92/38, No.12 Street, Quarter 18, Binh Hung Hoa Ward, Binh Tan District, Ho Chi Minh City, Vietnam.

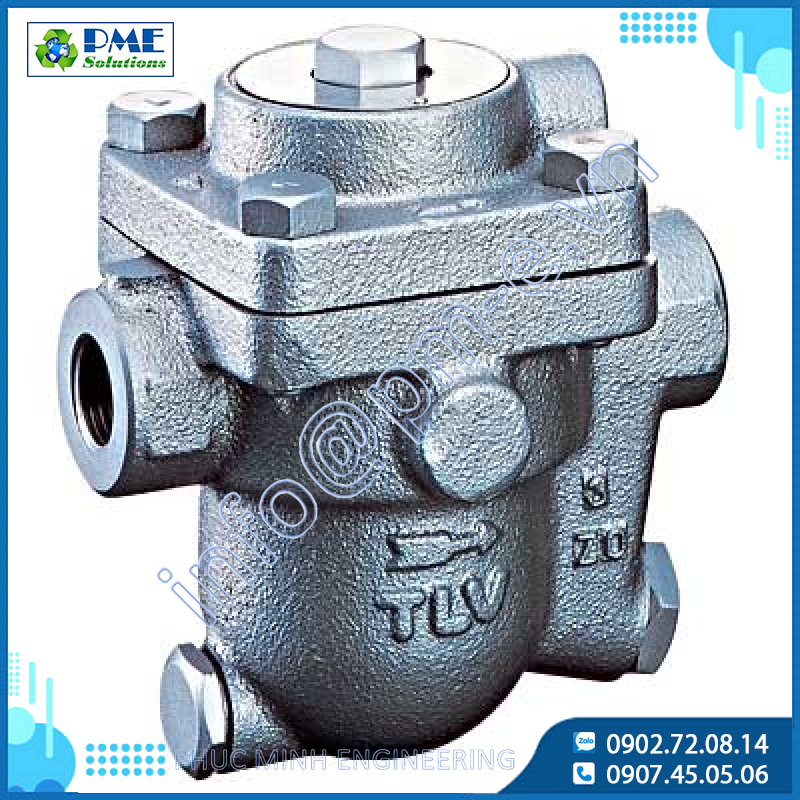

TLV Steam trap

PowerDyne® Disc-Type Steam Traps - P Series/HR Series/FP46UC

Price: Contact

PowerDyne® Disc-Type Steam Traps

P Series/HR Series/FP46UC

Pure performance for steam mains and tracers

Thermodynamic disc traps are valued for their compact size, versatility, and wide pressure range, but have you ever wondered how to improve their overall performance and extend their service life?

The TLV PowerDyne® series steam traps are designed to reduce product Life Cycle Cost. This includes reduced costs related to purchasing, installation, maintenance, and steam loss.

QuickTrap® Series Pamphlet (864 KB)

Benefits and Features

From Low Pressures to Super-high Pressures (26 MPa)

- Only at TLV, a line of thermodynamic (disc) steam traps has been developed that offers traps to cover the complete range of pressures used in the industrial world.

Energy Conservation

- Disc steam trap operation may suffer if the trap is exposed to cold air and rain. In order to prevent wasteful leakage of steam, TLV has developed an air-jacketed pressure chamber model, and for even greater insulation, a steam-jacketed pressure chamber model. The high-precision machined disc valve and valve seat offer excellent sealing properties, preventing wasteful discharge of steam.

Improved Productivity (Bimetal Type Automatic Air Venting Feature)

- Productivity is impaired if the large amounts of cold condensate and air inside the system are not discharged as soon as the equipment is started up. With the exception of models P21S, HR150A and HR260A, all models have an integral bimetal type automatic air venting feature. The valve is fully open when temperatures are low, allowing for the rapid discharge of cold condensate and air.

Easy Maintenance

- The valve and valve seat of all models (except for the P21S) are a single, modular unit, allowing for easy and economical maintenance when replacement is necessary due to wear, etc. For model FP46UC, both the module valve seat and the entire trap can be replaced inline.

Application Areas

-

Steam main lines, heat exchangers, jacketed kettles, room heating, tracers, coils, etc.

Product Details

| Model | Photo | Connection | Body Material | PMO (MPaG) | Minimum Operating Pressure (MPaG) | TMO (°C) | Discharge Capacity (kg/h) | Specification |

|---|---|---|---|---|---|---|---|---|

| P21S ver.C |

|

Screwed | Stainless Steel (ASTM A743 Gr.CA40) | 2.1 | Horizontal 0.025 Vertical 0.04 |

425 | 385 | Specification |

| P46S |

|

Screwed | Stainless Steel (ASTM A743 Gr.CA40) | 4.6* | 0.03 | 425 | 480 | Specification |

| P46SRN |

|

Screwed | Carbon Steel (ASTM A105) or Stainless Steel (ASTM A182 Gr.F304) | 4.6 | 0.03 | 425 | 740 | Specification |

| Socket Welded | ||||||||

| Flanged | Carbon Steel (ASTM A105) | |||||||

| P46SRM |

|

Screwed | Carbon Steel (ASTM A105) or Stainless Steel (ASTM A182 Gr.F304) | 4.6 | 0.03 | 425 | 1360 | Specification |

| Socket Welded | ||||||||

| Flanged | Carbon Steel (ASTM A105) | |||||||

| P46SRW |

|

Screwed | Carbon Steel (ASTM A216 Gr.WCB) | 4.6 | 0.03 | 425 | 2520 | Specification |

| Socket Welded | ||||||||

| Flanged | ||||||||

| P46UC-Y |

|

Two-Bolt Universal Flange | Cast Stainless Steel (ASTM A351 Gr.CF8) | 4.6 | 0.03 | 425 | 740 | Specification |

| P65SRN |

|

Screwed | Carbon (ASTM A105) or Stainless Steel (ASTM A182 Gr.F304) | 6.5 | 0.03 | 425 | 470 | Specification |

| Socket Welded | ||||||||

| Flanged | Carbon Steel (ASTM A105) | |||||||

| HR80A |

|

Socket Welded | Alloy Steel (ASTM A182 F22 Cl.3) | 8.0 | 0.8 | 475 | 190 | Specification |

| Flanged | ||||||||

| HR150A |

|

Socket Welded | Alloy Steel (ASTM A182 F22 Cl.3) | 15 | 1.6 | 550 | 220 | Specification |

| Flanged | ||||||||

| HR260A |

|

Socket Welded | Alloy Steel (ASTM A182 F22 Cl.3) | 26 | 1.6 | 550 | 230 | Specification |

| FP46UC |

|

Screwed | Stainless Steel (ASTM A351 Gr.CF8) | 4.6 | 0.03 | 425 | 740 | Specification |

| Socket Welded | ||||||||

| Flanged | ||||||||

| FP46UN |

|

Union | Stainless Steel (ASTM A351 Gr.CF8) | 4.6 | 0.03 | 400 | 740 | Specification |

| Pipe End |

- PMO = Maximum Operating Pressure

- TMO = Maximum Operating Temperature

Related projects

Category

Online support

Consulting - Quotation

Consulting-Technical

Consulting - Quotation

Consulting - Technical

Consulting - Quotation

Featured products

.png)