92/38, No.12 Street, Quarter 18, Binh Hung Hoa Ward, Binh Tan District, Ho Chi Minh City, Vietnam.

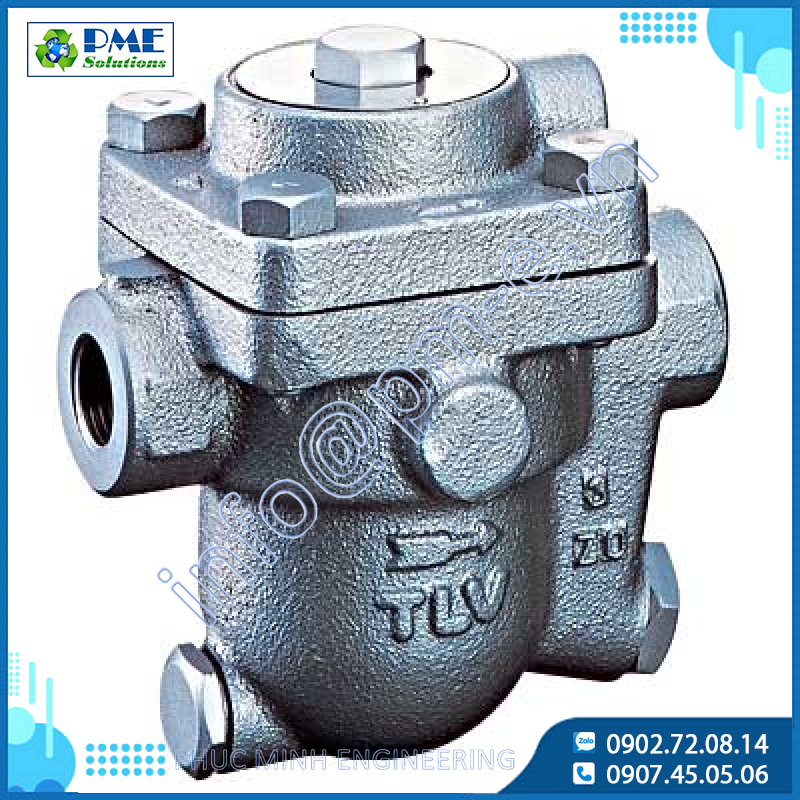

TLV Steam trap

Clean Steam Traps

LV6 Series

Stainless Steel Thermostatic Steam Trap for Pure and Clean Steam Systems

Balanced pressure thermostatic steam trap recommended for use in reactors, sterilizers and distribution lines in clean and pure steam systems.

Benefits and Features

The interior of these steam traps is designed to prevent corrosion and bacterial growth.

- All components are made of stainless steel.

- The X-element discharges hot air as well as low-temperature air and cold condensate. This encourages the inflow of steam, thereby reducing start-up times.

- Clamp connection at the joint allows for easy disassembly and cleaning.

Range of Products to Meet the Required Cleanliness Level

- Interior and exterior surfaces of the steam trap are available in three classes, natural machining, fine machining and buff-polishing. Models are also available with electro-polished surfaces for further improved to prevent bacterial growth.

Application Areas

Condensate removal from clean and pure steam.

- Bio industries

- Manufacture of pharmaceuticals

- Medical sterilizers

- Food production, etc.

Product Details

| Model | Photo | Connection | Body Material | PMO (MPaG) | TMO (°C) | Discharge Capacity (kg/h) | Finishing | X-element type | |

|---|---|---|---|---|---|---|---|---|---|

| Internal | External | ||||||||

| LV6-CE |

|

Clamp End / Tube End |

Stainless (AISI 316L) |

0.6 | 165 | 770 | Natural Machining | Natural Machining | Standard |

| LV6-SF | 0.8μm Ra Fine Machining |

1.2μm Ra Fine Machining |

Free-draining | ||||||

| LV6-P | 0.8μm Ra Buff Polished |

1.2μm Ra Buff Polished |

Free-draining (electro-polished) |

||||||

- PMO = Maximum Operating Pressure

- TMO = Maximum Operating Temperature

Related projects

Category

Online support

Consulting - Quotation

Consulting-Technical

Consulting - Quotation

Consulting - Technical

Consulting - Quotation

Featured products

.png)