92/38, No.12 Street, Quarter 18, Binh Hung Hoa Ward, Binh Tan District, Ho Chi Minh City, Vietnam.

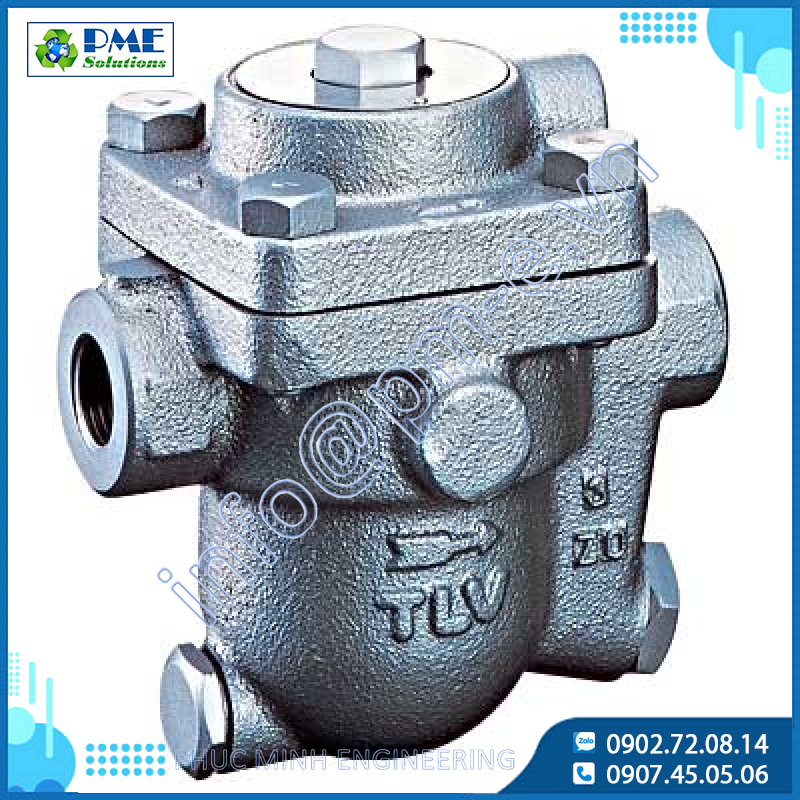

TLV Steam trap

Steam Trap Stations QS10 Series

Price: Contact

Steam Trap Stations

QS10 Series

Compact All Stainless Steel Steam Trap Station

Compact, reliable steam trap station for steam mains, tracers, and light processes. QuickStation enables condensate drainage from a wide range of applications, and inline replacement of universal flange steam traps in minutes.

QuickStation™ Pamphlet (756 KB)

Benefits and Features

- Simple trap selection and installationSteam traps can be installed in minutes, minimizing production downtime and with TLV's range of precision-engineered steam traps, allowing your process equipment to perform at optimal conditions.

- By making trap installation, replacement, and maintenance simple, costly steam trap problems can be rectified quickly, preventing energy loss and improving energy efficiency.

- Compact, reliable, all-in-one design

- QuickStation™ is of stainless steel construction for durability and corrosion resistance.

- Each QuickStation™ includes isolation valves, an integral strainer to help prevent equipment damage or production issues due to entrained material, and a check valve to prevent backflow.

- Compatible with the ideal steam trap for your application

- QuickStation™ is compatible with various steam trap units for condensate drainage from a wide range of applications, including light process use, tracers and steam mains.

- Flexible configuration for maximum reliability

- QuickStation™ is available with either single or double upstream/downstream isolation valves and multiple piping arrangements.

- QS10-B: one upstream and one downstream isolation valve

- QS10-D: two upstream and one downstream isolation valve

- QS10-T: tee fitting with two upstream and one downstream isolation valve.

- QS10-TD: tee fitting with two upstream and two downstream isolation valves.

- QuickStation™ is available with either single or double upstream/downstream isolation valves and multiple piping arrangements.

- Optional blowdown valve

- Elbow-type BD2 blowdown valve available for safer condensate blowdown and scale removal.

Application Areas

Simplifying installation and maintenance of steam trap and peripheral equipment.

Suitable for use where ease of steam trap installation and maintenance is critical, such as the pharmaceutical, food, and beverage industries, and for institutional use.

Product Details

| Model | Photo | Connection | Body Material | Overview | PMO (MPaG) | TMO (°C) | Specifications | Manual |

|---|---|---|---|---|---|---|---|---|

| QS10-B |

|

Screwed Socket Welded Flanged |

Cast Stainless Steel | One upstream and one downstream isolation valve | 1.0 | 185 | Specification | Manual |

| QS10-D |

|

Cast Stainless Steel | Two upstream and one downstream isolation valve | 1.0 | 185 | |||

| QS10-T |

|

Cast Stainless Steel | Tee fitting with two upstream and one downstream isolation valve | 1.0 | 185 | |||

| QS10-TD |

|

Cast Stainless Steel | Tee fitting with two upstream and two downstream isolation valves | 1.0 | 185 |

- PMO = Maximum Operating Pressure

- TMO = Maximum Operating Temperature

Related projects

Category

Online support

Consulting - Quotation

Consulting-Technical

Consulting - Quotation

Consulting - Technical

Consulting - Quotation

Featured products

.png)