92/38, No.12 Street, Quarter 18, Binh Hung Hoa Ward, Binh Tan District, Ho Chi Minh City, Vietnam.

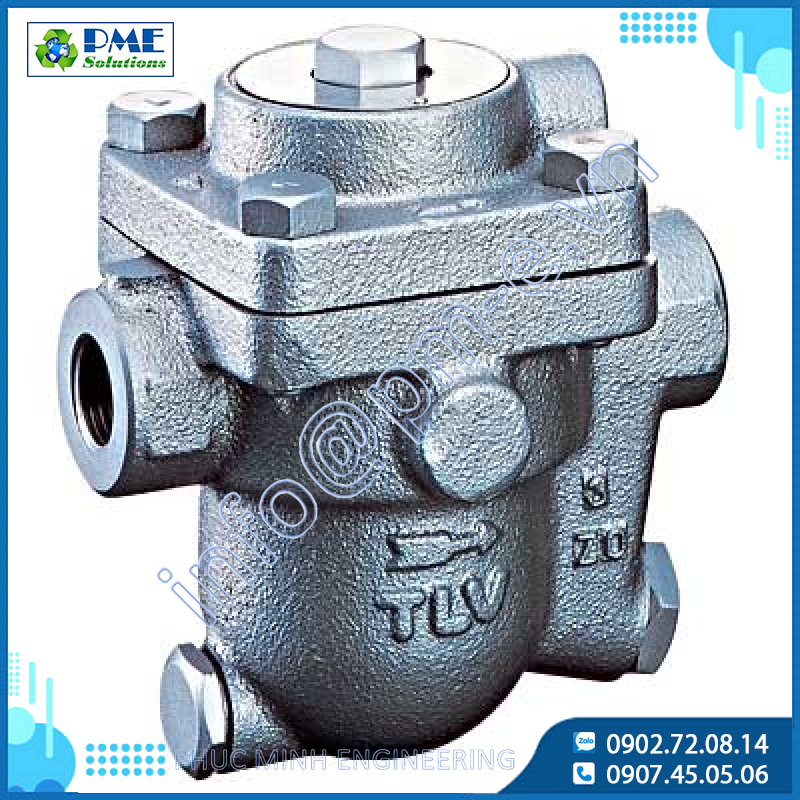

TLV Steam trap

Clean Steam Traps

SS Series

Free Float® steam traps for clean steam

Designed to allow complete condensate drainage and easy disassembly for cleaning.

Free Float® Steam Trap Series Pamphlet (1439 KB)

Benefits and Features

The interior of these steam traps is designed to prevent corrosion and bacterial growth.

- All components are made of stainless steel.

- Interior and exterior surfaces of the steam trap as well as the Free Float® itself are highly polished to produce smooth surfaces for improved resistance to bacterial growth.

- The clamp connection at the joint allows for easy disassembly and cleaning.

- A small built-in drain hole ensures complete condensate drainage to prevent the pooling of fluid.

Excellent Reliability

- The float rises and sinks as the flow of condensate fluctuates, opening the valve to discharge condensate and closing off the valve when steam enters. Free Float® design provides reliable operation.

Application Areas

Condensate removal from clean and pure steam.

- Bio industries

- Manufacture of pharmaceuticals

- Medical sterilizers

- Food production, etc.

Product Details

| Model | Photo | Connection | Body Material | PMO (MPaG) | TMO (°C) | Discharge Capacity (kg/h) |

Finishing | Specifications | |

|---|---|---|---|---|---|---|---|---|---|

| Internal | External | ||||||||

| SS3-E |  |

Clamp End | Stainless Steel (ASTM A351 Gr. CF3M) |

0.6 | 165 | 50 - 155 | 25μm Ra electro-polished | Specifications | |

| SS3-P | 0.8μm Ra buff-polished | 25μm Ra electro-polished | |||||||

| SS3-EP | Buff-polished then 0.4μm Ra electro-polished | ||||||||

| SS5-P |  |

170 - 500 | 0.8μmRa buff polished |

Bead-blasted and electro-polished | Specifications | ||||

- PMO = Maximum Operating Pressure

- TMO = Maximum Operating Temperature

Related projects

Category

Online support

Consulting - Quotation

Consulting-Technical

Consulting - Quotation

Consulting - Technical

Consulting - Quotation

Featured products

.png)