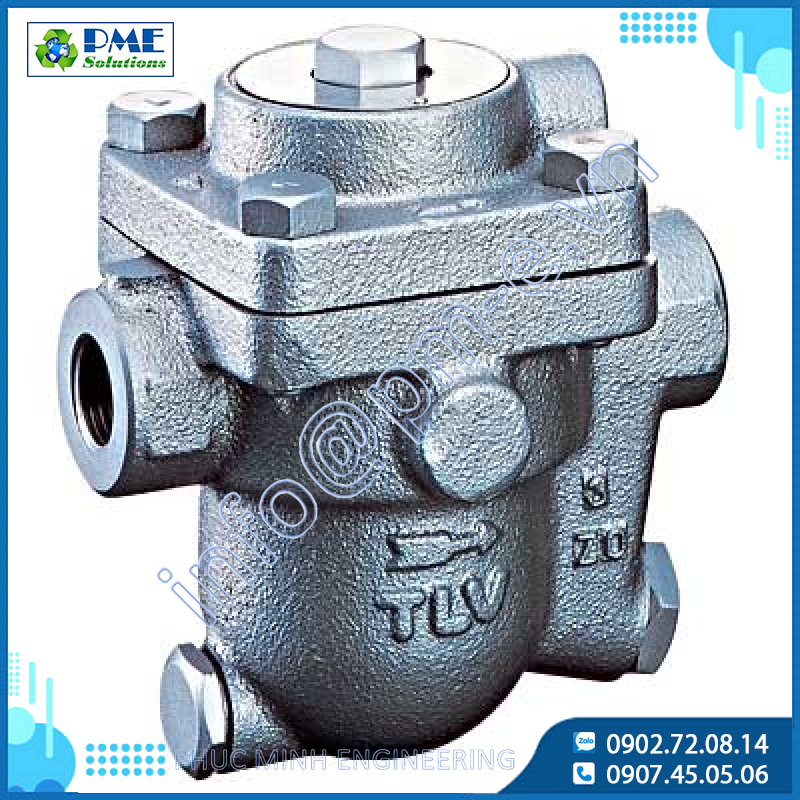

TLV Steam trap

Price: Contact

Free Float® Steam Traps (Low Pressure)

JX Series/FJ32 Series

Free Float® Steam Traps for Process Use

JX series steam traps can be installed on various types of equipment that uses steam as a heat source. The series covers a wide range of condensate loads, from the 100’s of kg/h to several 10’s of tons/h, making this TLV's most widely used series of steam traps.

In addition to offering compact size, continuous discharge of condensate, and large condensate discharge capacities, these steam traps are equipped with an X-element air-vent that provides a powerful automatic blow-out function. All these qualities gathered in one trap make the JX series ideal for steam-using equipment.

Free Float® Steam Trap Series Pamphlet (1439 KB)

J3S-X S Series Pamphlet (383 KB)

Benefits and Features

Improved Efficiency of Heating Equipment

- The Free Float® rises and sinks as the flow of condensate fluctuates, opening the valve to discharge condensate and closing off the valve when steam enters.

- The built-in X-element (model names including 'X') functions as an air vent, discharging both cool and hot air. As a result, the steam chamber inside the equipment contains only steam, which allows the equipment to achieve optimized heating performance.

Long Service Life, Excellent Durability

- The spherical Free Float® rotates during operation, allowing any point on its surface to act as the valve seal and thus ensuring long service life.

- Stainless steel models also available for increased durability.

Protects Equipment

- Fail Open' Design: The X-element is designed to fail open so that the valve remains open even in the event of failure.

Application Areas

Especially suitable for steam processes.

-

Heat exchangers, reactor kettles, vulcanizing pans, jacketed kettles, roller heat exchangers, cylinder dryers, etc.

Product Details

| Model | Photo | Connection | Body Material | PMO (MPaG) | TMO (°C) | Discharge Capacity (kg/h) | Specification |

|---|---|---|---|---|---|---|---|

| J3S-X |

|

Screwed | Cast Stainless Steel (ASTM A351 Gr.CF8) | 2.1 | 220 | 760 | Specifications |

| Flanged | |||||||

| J3S-X S1/S2 |

|

Screwed | Cast Stainless Steel | 1.4 | 220 | 600 | Specifications |

| Flanged | |||||||

| J3X |

|

Screwed | Ductile Cast Iron (FCD450) | 2.1 | 220 | 710 | Specifications |

| JF3X | Flanged | ||||||

| J5S-X |

|

Screwed | Cast Stainless Steel (ASTM A351 Gr.CF8) | 2.1 | 220 | 1020 | Specifications |

| Flanged | |||||||

| J5X |

|

Screwed | Ductile Cast Iron (FCD450) | 2.1 | 220 | 1040 | Specifications |

| JF5X | Flanged | Ductile Cast Iron Cast Iron (Sizes 32, 40, 50mm) |

|||||

| J6S-X |

|

Screwed | Cast Stainless Steel (ASTM A351 Gr.CF8) | 2.1 | 220 | 3530 | Specifications |

| J7.2X |

|

Flanged | Cast Iron (FCV400) | 1.6 | 220 | 9000 | Specifications |

| J7.5X |

|

Flanged | Cast Iron (FC250) | 1.6 | 220 | 15600 | Specifications |

| J7X |

|

Flanged | Cast Iron (FCV400) | 1.6 | 220 | 4000 | Specifications |

| J8X |

|

Flanged | Cast Iron (FC250) | 1.6 | 220 | 25000 | Specifications |

| FJ32-X QuickTrap® |

|

Universal flange | Stainless Steel | 3.2 | 240 | 670 | Specifications |

| FJ32-B QuickTrap® | 350 | 450 | Specifications |

- PMO = Maximum Operating Pressure

- TMO = Maximum Operating Temperature

Related projects

.png)