92/38, No.12 Street, Quarter 18, Binh Hung Hoa Ward, Binh Tan District, Ho Chi Minh City, Vietnam.

System Products

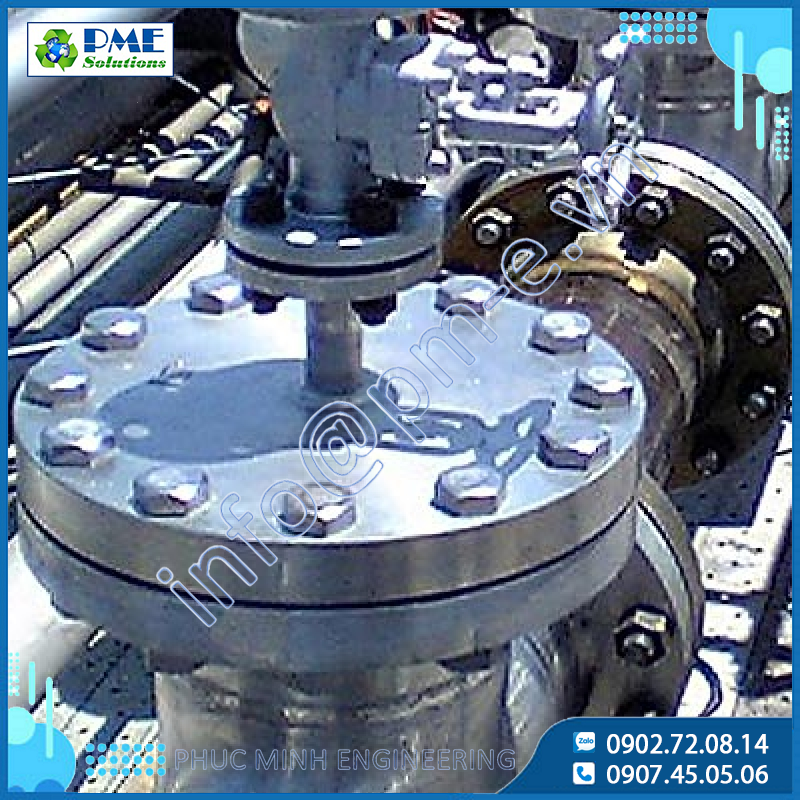

Vacuumizer (For Food and Beverage Plants) - VM2HU

Price: Contact

Vacuumizer (For Food and Beverage Plants)

Model VM2HU

High-precision low-temperature vacuum steam heating system.

Provides rapid start-up, uniform heating and accurate control of jacketed vessels, conical or cylinder dryers, and other process equipment.

Benefits and Features

- Package includes all necessary equipment including a control pane

- Easy-to-use touch panel

- Step heating control function enables shorter heating time

- Steam temperature control of ±1 °C ensures consistent production quality.

- Rapid vacuum generation function to enable shorter start-up times

- Built-in data logger

- Delivers heating temperature below 100 °C to improve manufactured quality of temperature sensitive products.

- Compared to hot water heating, temperature settings can be changed significantly faster.

- Packaged models facilitate piping installation.

Application Areas

Single equipment production processes and pilot plants.

- Jacketed reaction tanks (Capacity: up to 400 ℓ)

- Heating kettles, concentration kettles, cultivation kettles, dryers, kneading kettles, emulsification kettles, etc.

Product Details

| Model | Photo | Vacuum Steam Temperature Range |

Max. Vacuum Steam Capacity | Max. Heating Energy | Supply Steam Temperature Accuracy | Catalogue |

|---|---|---|---|---|---|---|

| VM2HU |

|

40℃1) - 110℃ | 390kg/h | 225kW (190Mcal/h) |

Set Temp ±1℃ | Specification |

1) Minimum steam temperature will be 25 °C above make up water temperature, e.g. steam temperature of 30 °C will require make up water at 5 °C

Related projects

Category

Online support

Consulting - Quotation

Consulting-Technical

Consulting - Quotation

Consulting - Technical

Consulting - Quotation

Featured products

.png)