92/38, No.12 Street, Quarter 18, Binh Hung Hoa Ward, Binh Tan District, Ho Chi Minh City, Vietnam.

System Products

Vacuum Steam Heating Systems - VM-H Series

Price: Contact

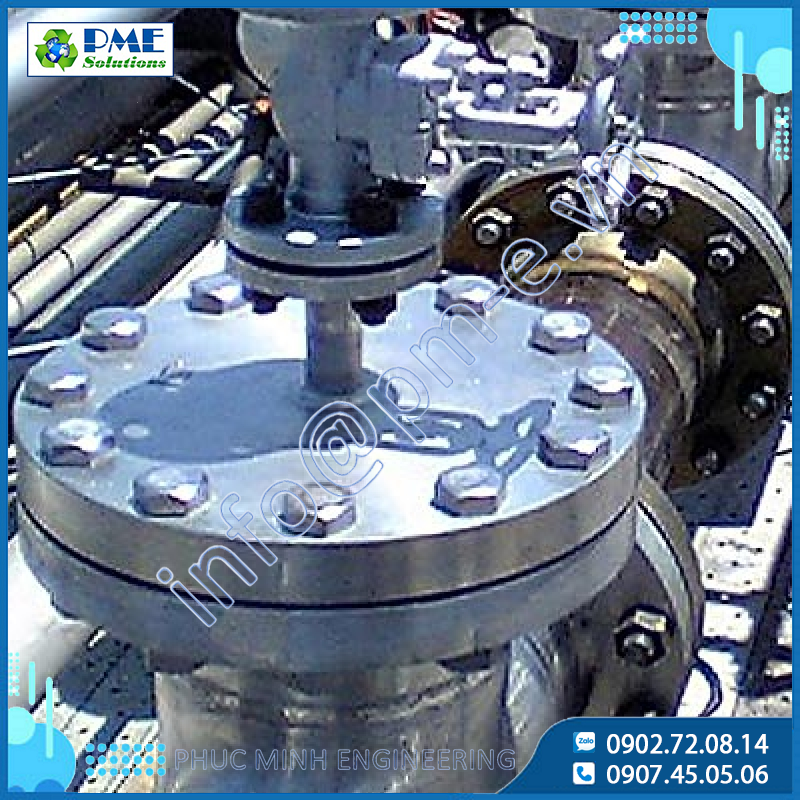

Vacuum Steam Heating Systems

VM-H Series

VACUUMIZER

An innovative heating method that utilizes vacuum steam for heating under 100 °C, and an innovative cooling method that utilizes vacuum technology for cooling.

Compact, but powerful: The TLV Vacuumizer combines high-efficiency vacuum creation, condensate recovery and accurate low pressure steam control. The result is a versatile solution for your steam heating needs which offers improved product quality and productivity

Benefits and Features

Vacuum Steam Heating System

- Steam heating below 100 ºC yields improved product quality and productivity.

- Uses saturated steam below atmospheric pressure as the heating source

- Heating by means of steam heat enables even heating of the equipment

- Steam is supplied precisely at the set temperature using desuperheat system

- Compared to heating with hot water, there is a great reduction in the time required for start-up and setting modifications

- Steam systems requires less space than hot water systems.

- Energy Conservation: The latent heat in the steam is used for heating, thereby greatly increasing the amount of heat per unit and allowing for low-cost heating using small amounts of steam

- Environmentally Friendly: The buffer tank used for hot water systems, and which creates great clouds of vapor, is not used

Vacuum Vaporization Cooling System

- This innovative cooling system utilizes the evaporative heat from the vaporization of water for cooling which allows for even cooling.

- Energy Conservation: Utilizes less water for cooling than conventional cold water circulation systems

Vacuum Steam Heating and Cooling System

- This system makes possible both heating and cooling using vacuum steam below 100 °C.

- The system switches quickly between heating and cooling.

- It combines the strengths of both a vacuum steam heating system and a vacuum vaporization cooling system.

Application Areas

Single equipment production processes and pilot plants - Package type: VM3HPN

- Jacketed reaction tanks (Capacity up to 10m3)

- Heating kettles, concentration kettles, cultivation kettles, dryers, kneading kettles, emulsification kettles, etc.

Multi-equipment product processes and pilot plants - Package type: VM4HP

- Jacketed reaction tanks(Capacity per one unit: up to 7m3)

- Shell and tube type heat exchangers, hot air dryers, roll heaters, etc.

Engineering Type

- Jacketed reaction tanks

- Shell and tube type heat exchangers

- Roll heaters, etc.

Product Details

| Model | Photo | Type | Vacuum Steam Temperature Range | Max. Vacuum Steam Capacity | Max. Heating Energy | Supply steam temp. accuracy | Catalogue |

|---|---|---|---|---|---|---|---|

| VM3HPN |

|

System Package | 30℃ - 150℃ | 4500kg/h | 2600kW(2240Mcal/h) | Set temp. ±1℃ | Specifications |

| VM4HPN(*1) |

|

||||||

| VM |

|

Engineered package |

- *1: VM4HPN's control panel is an option.

Related projects

Category

Online support

Consulting - Quotation

Consulting-Technical

Consulting - Quotation

Consulting - Technical

Consulting - Quotation

Featured products

.png)