DIDTEK Steel Valves for Oil & Gas and General Industrial

DIDTEK Steel Valves for Oil & Gas and General Industrial

1. Company Overview

DIDTEK Valve Group, established in 1985, is one of China’s leading industrial valve manufacturers. The company is headquartered in Lin Yang Industrial Zone, Oubei Town, Yongjia County, Zhejiang Province. DIDTEK specializes in the design, production, and export of high-quality industrial valves, serving industries such as oil & gas, petrochemicals, power generation, marine, water treatment, and more.

.JPG)

2. Main Products

-

Gate Valves

-

Globe Valves

-

Ball Valves (Floating Ball Valves, Trunnion Mounted Ball Valves)

-

Butterfly Valves

-

Check Valves

-

Y-Strainer

-

Knife Gate Valves

-

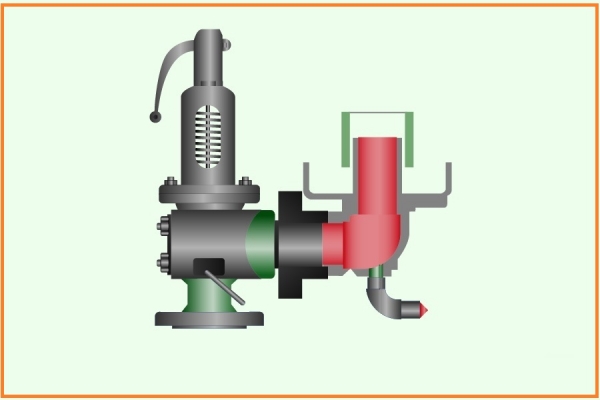

Safety Valves

-

Valves for high temperature, high pressure, and cryogenic applications

DIDTEK Steel Gate Valves

3. Key Strengths

-

Advanced CNC machining and production technologies.

-

Certified to international standards: API 6D, API 607/6FA, ISO 9001, CE PED, UKCA, EAC, ISO 15848...

-

100% product pressure testing and strict quality control before shipment.

-

Official warranty from 12 to 18 months depending on product category.

.jpg)

DIDTEK Steel Ball Valves

4. Typical Applications

-

Power plants, oil refineries, chemical plants.

-

HVAC systems, industrial water and wastewater systems.

-

LNG, CNG, industrial gases, offshore oil and gas facilities.

.jpg)

Didtek Steel Valves

5. Authorized Distributor in Vietnam

For the Vietnamese market, DIDTEK has officially appointed:

Phuc Minh Engineering Co., Ltd. (PME)

Authorized Distributor for DIDTEK Industrial Valves in Vietnam.

-

Phone/Zalo:

☎️ +84 902 720 814 – +84 907 450 506 -

Email:

📧 info@pm-e.vn -

Website:

🌐 www.pm-e.vn -

Office Address:

92/38, Street 12, KP18, Binh Hung Hoa Ward, Binh Tan District, Ho Chi Minh City, Vietnam -

Technical Support & Quotation Hotline: +84 907 450 506 (Mr. Duong)

.jpg)

DIDTEK Steel Ball Valves

6. Why Buy from the Official Distributor?

-

Guaranteed genuine DIDTEK products with full CO, CQ documentation.

-

Free technical consultation and valve selection support.

-

Official product warranty and after-sales technical assistance.

-

Competitive pricing through direct importation without intermediaries.

For catalog files, technical specifications in PDF, or quick quotations, please contact Phuc Minh Engineering directly!

(1).JPG)

Related News

VinVal Industrial Water Valves: Stainless Steel Globe Valves & Pipeline Solutions from PM-E

20/12/2025

Discover high-quality VinVal industrial water valves. PM-E specializes in providing stainless steel globe valves and diverse fluid control solutions for your pipeline systems.

Steam Energy-Saving Solutions for Factories | Phuc Minh Engineering

17/12/2025

Optimize your steam system with Phuc Minh Engineering. Reduce energy loss, increase boiler efficiency, and cut fuel costs by 10–30%. Contact us now.

Flow Measurement & Pressure Control Solutions.

17/12/2025

Solutions for measuring flow and controlling pressure in steam, air, water, oil, and chemical systems. Optimize operations – reduce losses – enhance safety. Contact Phuc Minh.

What Is a Pressure Reducing Valve? Structure – Working Principle – How to Select the Best PRV for Industrial Plants (2025)

17/12/2025

A Pressure Reducing Valve (PRV) is a device used to reduce high inlet pressure to a stable, lower outlet pressure, helping protect piping systems, instruments, and machinery while improving operational safety. PRVs are widely used in: Steam systems Compressed air, gas, nitrogen Clean water – process water – chilled water Oil, chemicals, and other industrial media

Safety Valve For Steam Systems: Structure, Operation Principles & Selection Guide 2025 | Phuc Minh Engineering

17/12/2025

Learn what a steam safety valve is, how it works, different types, and how to select the correct valve for boilers and pipelines. EN/ASME-standard valves from Phuc Minh Engineering.

.JPG)

.png)