VinVal Industrial Water Valves: Stainless Steel Globe Valves & Pipeline Solutions from PM-E

ndustrial pipeline systems are likened to the blood vessels of every factory, and industrial water valves are the vital "organs" that regulate the flow. Whether you are operating a water treatment, food processing, or chemical plant, choosing the right valve type and a reputable supplier is key to ensuring operational efficiency.

In this article, we will delve into industrial valve lines, specifically the VinVal brand distributed by PM-E, as well as the common fluids that systems typically handle.

I. What are Industrial Water Valves and their role in the system? Industrial Water Valves are mechanical devices used to close, open, regulate flow, or change the direction of the flow within a pipeline. Unlike common residential valves, industrial valves are designed to withstand high pressure, extreme temperatures, and corrosive working environments.

Their role is not limited to just "turning off the tap." In complex systems, valves help:

-

Protect pumps and measuring equipment.

-

Prevent backflow causing damage (check valves).

-

Precisely regulate flow to serve production processes (globe valves).

II. Common types of media in industry When mentioning "water valves," many people only think of clean water. However, in the industrial environment, the term "media" (fluid) covers a much broader scope. At PM-E, we provide VinVal valve solutions suitable for a wide variety of media:

-

Water This is the most common media, including clean water, cooling water, and wastewater. For wastewater containing impurities, gate valves or butterfly valves are often prioritized.

-

Steam and Gas In boilers or drying systems, valves must withstand very high temperatures and pressures. At this point, the valve manufacturing material plays a decisive role.

-

Chemicals and Solvents In the food or textile dyeing industries, media often have acidic or alkaline properties. This is where the stainless steel globe valve proves its effectiveness thanks to its excellent corrosion resistance.

III. VinVal Stainless Steel Globe Valve: The Durable Choice Among the products that PM-E supplies, the stainless steel globe valve from the VinVal brand is always a "best-seller" thanks to its superior characteristics.

Why Stainless Steel (Inox)? Stainless steel (usually 304 or 316) has strong oxidation resistance. This is particularly important when the valve must frequently contact water or chemicals. VinVal stainless steel globe valves not only ensure durability and long lifespan but also maintain brightness and are easy to clean, suitable for food factories requiring high hygiene safety.

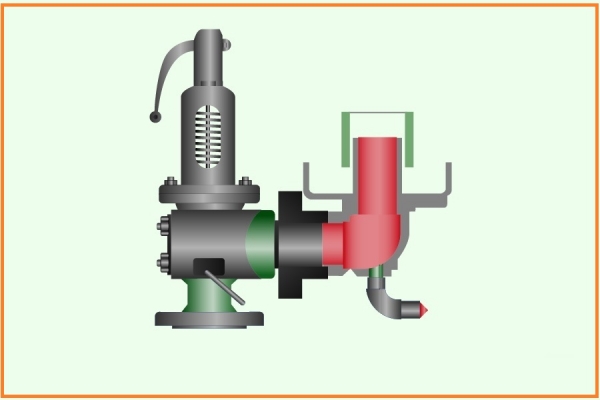

Precise Regulation Capability Unlike ball valves or gate valves used only for full open/close, the Globe Valve is specifically designed to regulate flow rate. The spherical or conical disc design helps operators precisely control the amount of media passing through the pipeline.

IV. Why choose PM-E as your VinVal valve supplier? The current industrial valve market is chaotic with many floating goods of poor quality. PM-E is proud to be a reputable unit specializing in distributing genuine products from VinVal.

Benefits of partnering with PM-E:

-

Diverse Variety: We supply all types of VinVal valves: from gate valves, butterfly valves, ball valves to globe valves, check valves...

-

In-depth Technical Advice: The PM-E team understands the technical characteristics of each type of valve used in water pipelines, helping you choose the right valve for the right media.

-

Stock Availability: Quickly responding to replacement, repair, or new installation needs for large projects.

V. Frequently Asked Questions (FAQ) Below are the questions that customers often send to PM-E when looking to buy industrial valves:

-

Can VinVal industrial water valves withstand chemicals? Yes. Especially the valve lines made from Inox 304 or 316 materials by VinVal have very good corrosion resistance, suitable for many industrial chemicals.

-

How to distinguish between a globe valve and a gate valve? A Gate Valve is typically used to fully open/close the flow and has low flow resistance when fully open. A Globe Valve has a directional flow design (Z-shape or bulbous), used for more precise flow regulation but causes a higher pressure drop.

-

Does PM-E support shipping valves to provinces? PM-E supports nationwide shipping. For large project orders, we have policies to support transportation and on-site installation consultation.

-

What is the average lifespan of a stainless steel globe valve? If maintained periodically and used within correct pressure/temperature parameters, VinVal stainless steel globe valves can operate durably for 5-10 years or more.

Choosing the right industrial water valve not only helps the system operate smoothly but also saves long-term maintenance costs. Contact PM-E immediately for advice on the most optimal VinVal valve solution for your factory.

Related News

Steam Energy-Saving Solutions for Factories | Phuc Minh Engineering

17/12/2025

Optimize your steam system with Phuc Minh Engineering. Reduce energy loss, increase boiler efficiency, and cut fuel costs by 10–30%. Contact us now.

Flow Measurement & Pressure Control Solutions.

17/12/2025

Solutions for measuring flow and controlling pressure in steam, air, water, oil, and chemical systems. Optimize operations – reduce losses – enhance safety. Contact Phuc Minh.

What Is a Pressure Reducing Valve? Structure – Working Principle – How to Select the Best PRV for Industrial Plants (2025)

17/12/2025

A Pressure Reducing Valve (PRV) is a device used to reduce high inlet pressure to a stable, lower outlet pressure, helping protect piping systems, instruments, and machinery while improving operational safety. PRVs are widely used in: Steam systems Compressed air, gas, nitrogen Clean water – process water – chilled water Oil, chemicals, and other industrial media

Safety Valve For Steam Systems: Structure, Operation Principles & Selection Guide 2025 | Phuc Minh Engineering

17/12/2025

Learn what a steam safety valve is, how it works, different types, and how to select the correct valve for boilers and pipelines. EN/ASME-standard valves from Phuc Minh Engineering.

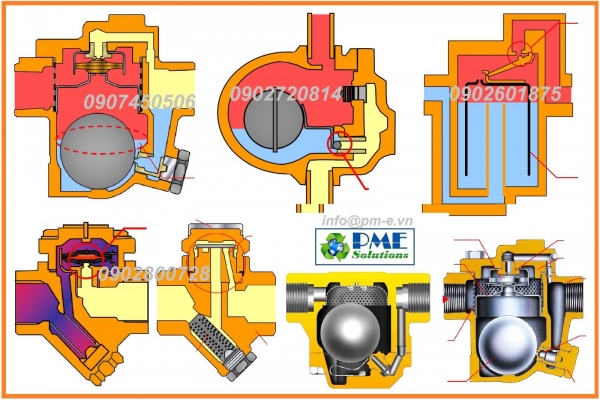

What Is a Steam Trap? Classification – Structure – How to Select the Right Trap for Steam Systems (2025 Guide) | Phuc Minh

17/12/2025

A steam trap is a device used to discharge condensate while retaining live steam inside pipelines or steam-using equipment. Its main functions include: Removing condensate at the right time Preventing steam loss Improving heat transfer efficiency Protecting equipment from water hammer Reducing boiler fuel consumption A steam trap acts like an “automatic valve” that distinguishes steam from condensate based on temperature, pressure, and density.

.png)