What Is an Industrial Valve? Types, Applications, and How It Works

What Is an Industrial Valve? Types, Applications, and How It Works

Industrial valves may seem like small components, but they play an essential role in the operation of countless modern piping systems. From large-scale manufacturing plants to residential water supply and drainage systems, industrial valves are always present, performing critical functions that help control fluid flow safely and efficiently.

So, what exactly is an industrial valve? What types are there? How do they operate, and in which industries are they commonly applied? Let’s explore these questions in detail with Phuc Minh Engineering in the article below.

What Is an Industrial Valve? Functions and Basic Types of Industrial Valves

Definition of Industrial Valve

An industrial valve is a specialized mechanical device installed directly on piping systems to control the flow of fluids. These fluids may include liquids such as water, oil, and chemicals; gases such as compressed air and gas; or even solid materials in powder or mixed granular form.

Core Functions of Industrial Valves:

-

Open/Close Flow: Allow or completely block the movement of fluid through the pipeline.

-

Flow Regulation: Control the volume of fluid passing through according to the system's technical requirements.

-

Pressure Adjustment: Maintain stable pressure within the pipeline, protecting other equipment from abnormal overpressure or pressure drops.

-

Flow Direction Switching: Distribute fluid to different pipeline branches, changing flow direction when necessary.

-

System Protection: Prevent incidents such as backflow or sudden pressure surges, ensuring safety and durability for the entire system.

Industrial valves play a vital role in helping systems operate stably, safely, and efficiently. Choosing the right type of valve for each application helps improve performance and extend the service life of both equipment and the entire piping system.

Popular Types of Industrial Valves – Classified by Function

Industrial valves are categorized into various types based on their function, structure, and operating method. Below is a basic classification according to function:

-

On/Off Valves

-

Ball Valve: Simple design, very fast open/close capability, suitable for bidirectional flow.

-

Gate Valve: Slow opening and closing, minimal pressure loss, commonly used for large-diameter piping systems.

-

Butterfly Valve: Compact structure, easy to install, flexible flow control.

-

Globe Valve: Offers precise flow regulation, capable of handling high pressure.

-

Knife Gate Valve: Suitable for fluids containing impurities such as sludge or sediment.

Summary of Lever-Operated Ball Valve Types

-

Gate Valve: Slow opening and closing, minimal pressure loss, commonly used for large-diameter pipelines. Learn more: What is a Gate Valve?

Gate valves

-

Butterfly Valve: Compact and lightweight, easy to install, provides flexible flow control. Learn more: What is a Butterfly Valve?

Butterfly Valve

-

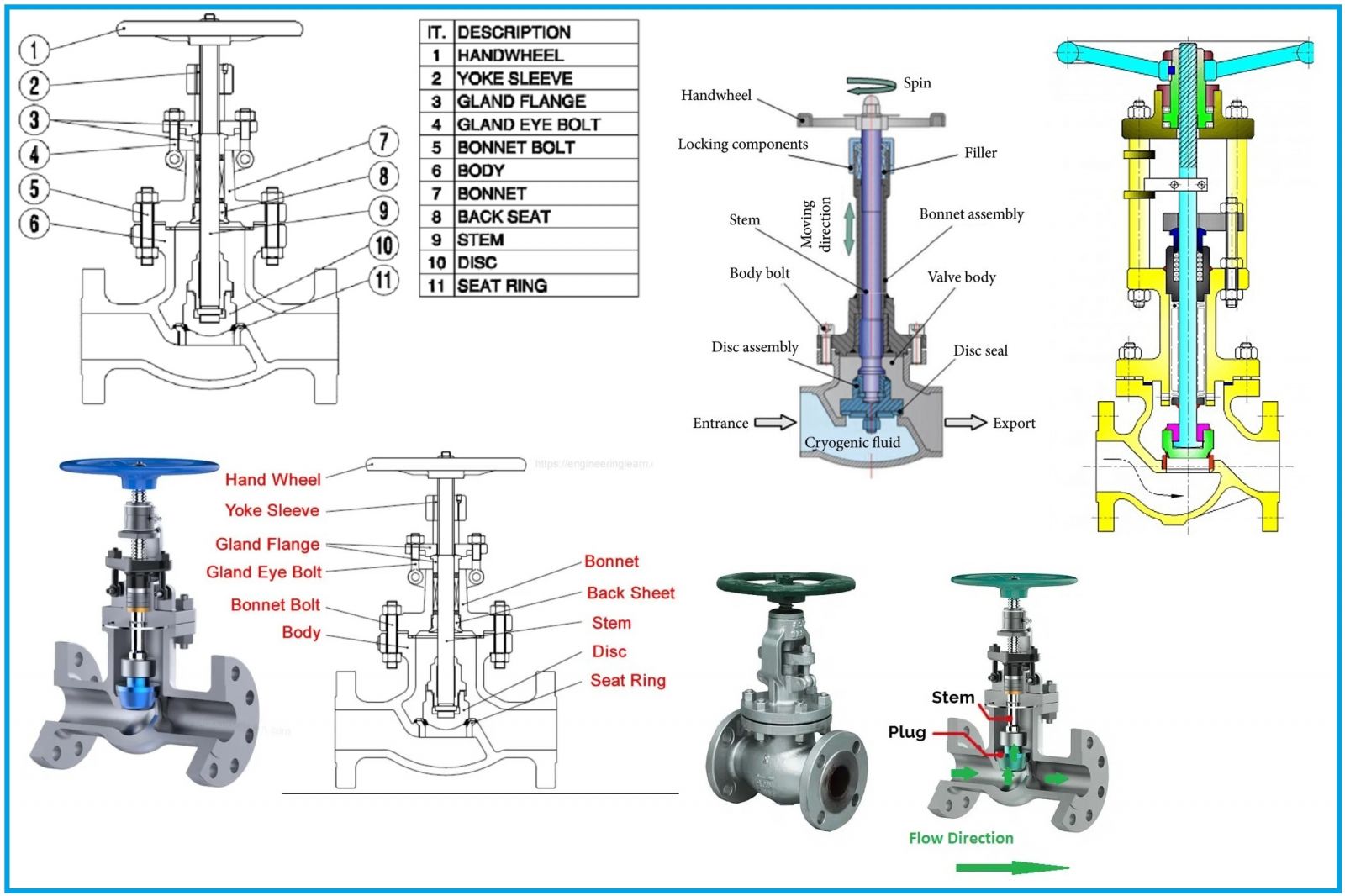

Globe Valve: Precise flow regulation, capable of withstanding high pressure. Learn more: What is a Globe Valve?

Globe valves

-

Knife Gate Valve: Designed for fluids containing impurities, sludge, or slurry. View product.

Regulating Valve

- Needle Valve: Provides highly precise flow control, commonly used for small flow rates. View product.

-

Angle Valve: Regulates flow and changes the direction of the fluid. View product.

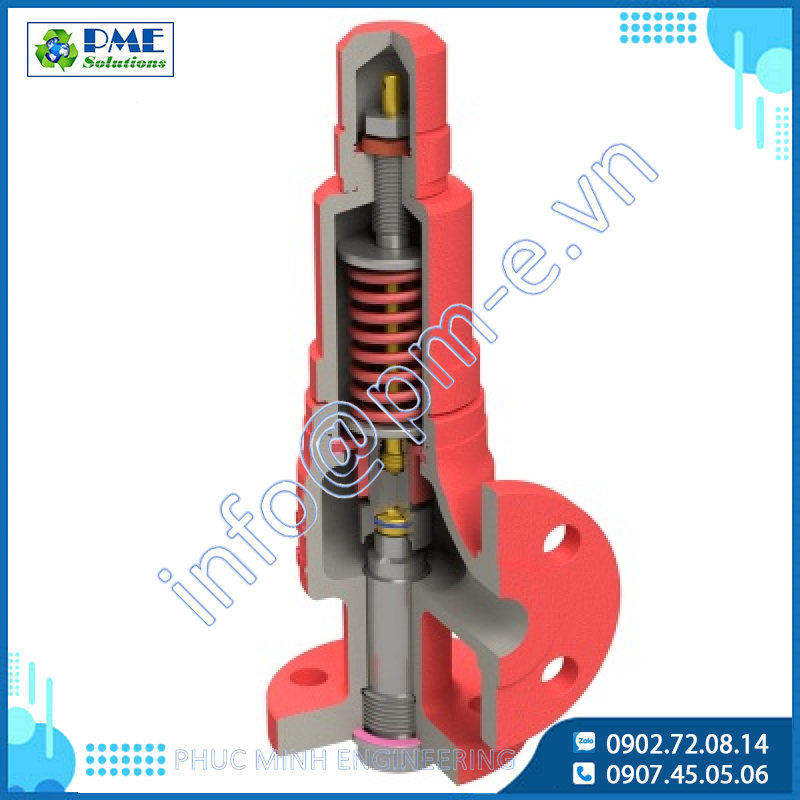

Safety Valve

-

Safety Valve: Releases pressure when it exceeds the allowable limit, protecting the system. Learn more: What is a Safety Valve?

.jpg)

-

Pressure Reducing Valve: Lowers pressure to the required level, maintaining stable system pressure. Learn more: What is a Pressure Reducing Valve?

-

Pressure Relief Valve: Releases excess pressure from the system. View product.

- Check Valve: Allows fluid to flow in only one direction, preventing backflow. View product.

Specialty Valves

-

Y-Strainer: Removes impurities from the fluid. View product.

-

Drain Bottom Valve: Discharges sediment, sludge, and debris accumulated at the bottom of tanks or pipelines. View product.

Industrial Valve Classification by Structure

-

Gate Valve (Slide Gate Valve): Uses a gate or disc moving up and down to control the opening and closing of flow in the pipeline.

-

Globe Valve: The valve disc moves upward or downward to adjust liquid flow according to operational needs.

-

Butterfly Valve: The valve disc rotates around its axis to open, close, or regulate the amount of fluid passing through.

-

Ball Valve: Contains a perforated ball inside that rotates to either allow or block fluid flow.

-

Swing Check Valve: The disc tilts horizontally to allow one-way fluid flow and prevents backflow.

-

Lift Check Valve (Butterfly Check Valve): The disc moves vertically; should not be installed horizontally to maintain proper backflow prevention function.

-

Needle Valve: Similar to a globe valve but with a needle-shaped conical disc, offering highly precise flow regulation.

-

Diaphragm Valve: Utilizes a flexible diaphragm to open or close the flow by lifting or pressing the diaphragm up or down.

-

Knife Gate Valve: Features a blade-like disc sliding up and down to control flow, ideal for fluids containing impurities.

Industrial Valve Classification by Material

Stainless Steel Valves:

- Advantages: Corrosion resistance, high durability, capable of withstanding high temperature and pressure environments, ensures food-grade hygiene.

- Applications: Commonly used in food and beverage, pharmaceutical, potable water, and industrial chemical systems.

Popular stainless steel types: 304 stainless steel, 316 stainless steel, and 316L stainless steel depending on technical requirements and safety standards.

Steel Valves:

Advantages:

- High strength and durability, capable of withstanding very high pressure and temperature conditions.

Applications:

- Widely used in industries such as oil & gas, energy, and heavy industry.

Common Steel Types:

- Carbon steel, alloy steel, and other specialized steel grades depending on system requirements.

Brass and Bronze Valves:

Advantages:

Corrosion-resistant, excellent thermal conductivity, easy to machine and fabricate.

Applications:

Used in pneumatic systems, air conditioning, gas pipelines, and related applications.

Common Copper Alloys:

Brass (yellow copper), bronze (red copper), and other copper-based materials depending on usage requirements.

Plastic Valves:

Advantages:

Corrosion-resistant, lightweight, cost-effective.

Applications:

Widely used in wastewater treatment systems, irrigation systems, and chemical processing.

Common Plastic Types:

PVC (Polyvinyl Chloride), UPVC (Unplasticized PVC), CPVC (Chlorinated PVC), PVDF (Polyvinylidene Fluoride), and others depending on chemical resistance and temperature requirements.

Classification by Operating Mechanism

Manual Operated Valves (Hand-Operated Valves):

Advantages:

- Simple design, easy to operate, low cost, suitable for systems that do not require automation.

Disadvantages:

- Slower opening/closing time, cannot be integrated into automated control systems.

Common Types:

- Lever-operated valves, handwheel-operated valves, gear-operated valves, wheel-handle valves, and similar manual control designs.

Automatic Control Industrial Valves

Advantages:

- Fast opening/closing speed, highly precise flow and pressure control, easily integrated into industrial automation systems.

Disadvantages:

- More complex structure compared to manual valves, higher investment and maintenance costs.

Common Types of Automatic Control Valves:

-

Pneumatic Control Valves: Operated using compressed air pressure to control the valve’s opening and closing mechanism.

-

Electric Control Valves: Use electric motors to perform opening, closing, or adjusting the valve’s opening angle.

-

Hydraulic Control Valves: Utilize hydraulic oil pressure to operate the valve, suitable for systems requiring high torque and demanding working conditions.

Practical Applications of Industrial Valves in Manufacturing and Residential Sectors

Industrial valves today are widely applied across various industries—from manufacturing, food processing, and chemicals to residential systems—playing a key role in ensuring stable, safe, and efficient system operations.

Applications in the Clean Water Industry

-

Water Supply Systems: Gate valves, butterfly valves, and control valves are installed to regulate flow and pressure in municipal and industrial water supply networks, ensuring continuous water delivery for both living and production needs.

-

Wastewater Treatment: Check valves, knife gate valves, and diaphragm valves control flow direction, prevent backflow, and protect water resources and the environment.

-

Irrigation Systems: Solenoid valves, control valves, and ball valves are integrated into automated irrigation systems, saving water and improving agricultural productivity.

Applications in the Oil & Gas Industry

-

Exploration: Safety valves and high-pressure gate valves are used on drilling rigs to control oil and gas flow, ensuring maximum safety.

-

Transportation: High-pressure, corrosion-resistant ball valves and globe valves are installed on pipelines transporting oil and gas under harsh conditions.

-

Processing: Control valves and needle valves precisely manage flow and pressure in refineries and petrochemical plants.

Applications in the Food Industry

-

Production & Processing: Butterfly valves, stainless steel ball valves, and diaphragm valves ensure food safety and hygiene, preventing contamination during production.

-

Mixing & Blending: Check valves and mixing valves help accurately mix ingredients, maintaining product quality.

-

Packaging: Solenoid valves and pneumatic valves automate packaging processes, boosting productivity.

Applications in the Chemical Industry

-

Production Processes: Globe valves, ball valves, and control valves regulate flow, temperature, and pressure, ensuring chemical safety.

-

Chemical Mixing: Mixing valves and proportioning valves ensure precise chemical dosing.

-

Chemical Transportation: Safety valves and check valves protect systems from leaks and contamination risks.

Applications in Fire Protection Systems

-

Fire Water Supply: Gate valves and butterfly valves control water flow to sprinklers and fire hoses.

-

Fire Alarm Systems: Alarm valves and fire check valves send early signals and prevent fire spread.

Applications in HVAC (Heating, Ventilation, and Air Conditioning)

-

Temperature Control: 3-way valves and temperature control valves adjust room temperature and humidity in buildings and factories.

-

Ventilation: Butterfly valves and air control valves regulate airflow, ensuring a clean and ventilated environment.

Applications in Other Industrial Sectors

-

Pharmaceuticals: Diaphragm valves and stainless steel ball valves are used in medicine production lines requiring strict hygiene and precision.

-

Cement Industry: Gate valves and butterfly valves handle abrasive materials in raw material transport systems.

-

Paper Industry: Globe valves and control valves manage liquid flow in paper production processes.

-

Textile Industry: Solenoid valves and pneumatic valves support automation in dyeing and fabric finishing equipment.

Phuc Minh Engineering specializes in supplying genuine industrial valves tailored to each specific application across the industries mentioned above.

Please contact us for expert consultation and support in selecting the optimal valve solutions for your system.

Operating Principles of Common Industrial Valves

Understanding how each type of valve operates helps ensure proper selection, efficient operation, and easier maintenance of your system. Below are the basic operating principles of several commonly used valve types:

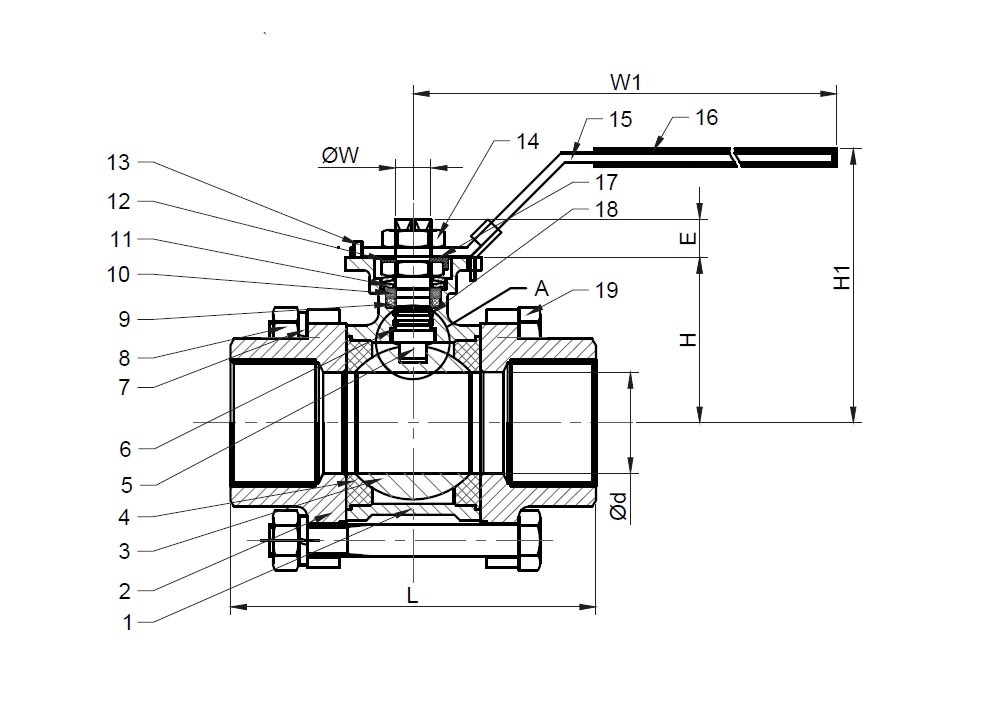

Ball Valve

Structure: Includes valve body, a perforated ball (ball with a hole through it), valve seat, valve stem, and handle or lever.

Operating Principle:

When the handle or lever is turned, the ball inside rotates.

-

If the hole in the ball aligns with the pipeline, the fluid flows through.

-

If the hole is perpendicular to the pipeline, flow is blocked.

Key Advantages:

-

Quick opening and closing

-

Simple design, minimal leakage

Common Applications:

-

Suitable for on/off control in systems where fast operation is needed.

Operating Principle of Ball Valves

When the handle or lever is turned, the valve stem rotates the internal ball.

-

When the hole inside the ball aligns with the pipeline, fluid is allowed to flow through.

-

When the hole is turned perpendicular to the pipeline, the flow is completely blocked.

Advantages:

-

Fast open/close operation.

-

Simple structure, minimizes leakage.

Limitations:

-

Not suitable for precise flow regulation; mainly used for fully open or fully closed positions.

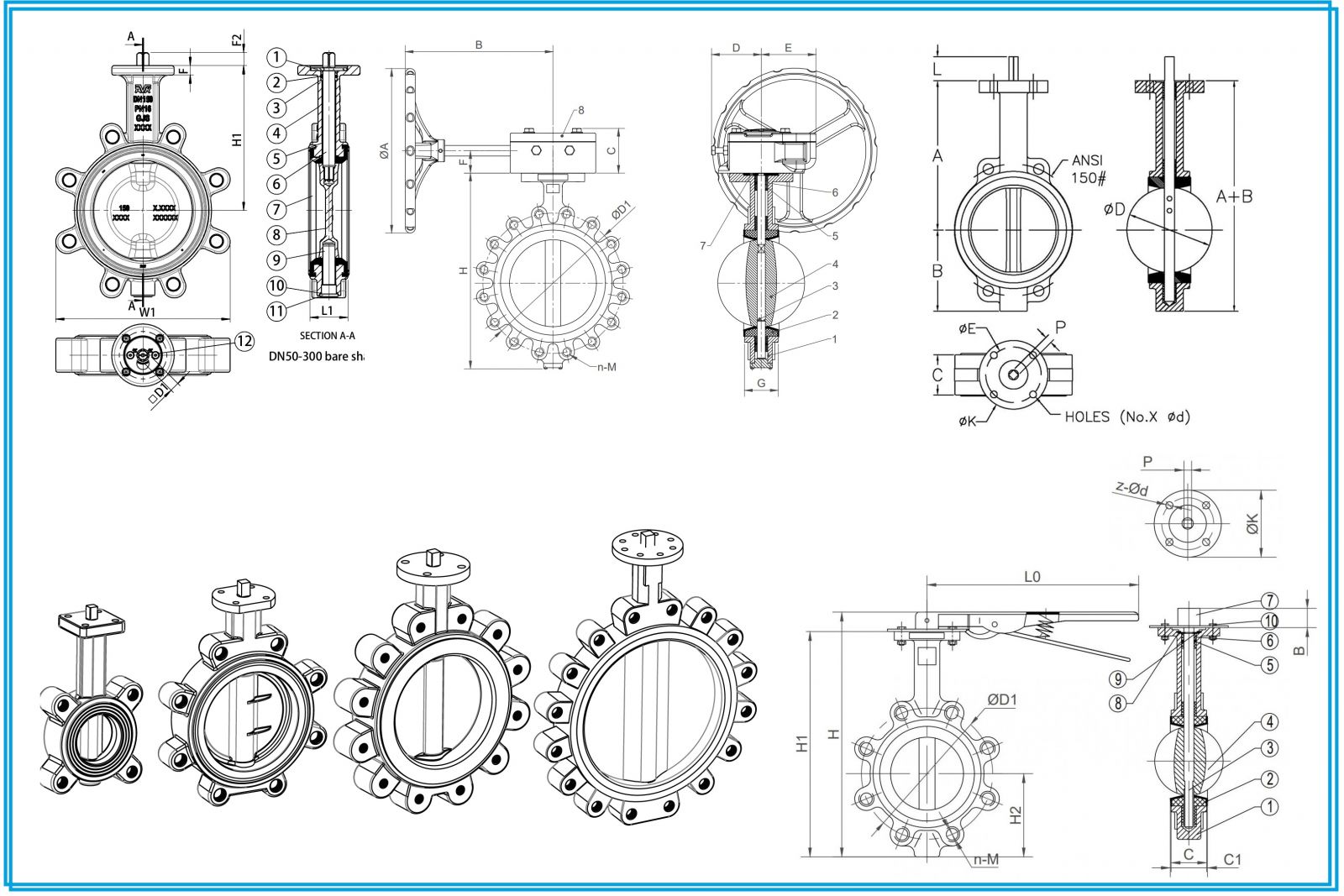

Butterfly Valve

Structure:

Includes valve body, valve disc, valve seat, valve stem, and handle or actuator.

Operating Principle:

When the handle or actuator rotates the valve stem, the disc rotates around its axis:

-

When the disc is parallel to the flow direction, fluid passes through freely.

-

When the disc is turned perpendicular to the flow, the valve blocks the fluid completely.

Advantages:

-

Compact, lightweight design.

-

Easy to install and operate.

-

Flexible flow control, suitable for throttling or full open/close applications.

Limitations:

-

Lower pressure and temperature resistance compared to gate valves or ball valves.

-

May cause more flow turbulence when partially open.

-

Operating Principle:

When the valve shaft is rotated, the disc attached to the shaft turns accordingly. This rotation changes the opening area inside the valve, allowing adjustment of the flow rate through the pipeline. -

When the disc is fully aligned with the flow direction, maximum flow is allowed.

-

When the disc is turned perpendicular to the flow, the valve blocks the flow entirely.

-

Advantages:

-

Compact and lightweight design, saving installation space.

-

Easy and quick to install.

-

Simple operation with flexible flow control, allowing precise adjustment based on system needs.

-

Disadvantages:

-

Lower pressure resistance compared to ball valves and gate valves.

-

Best suited for medium- or low-pressure systems rather than high-pressure applications.

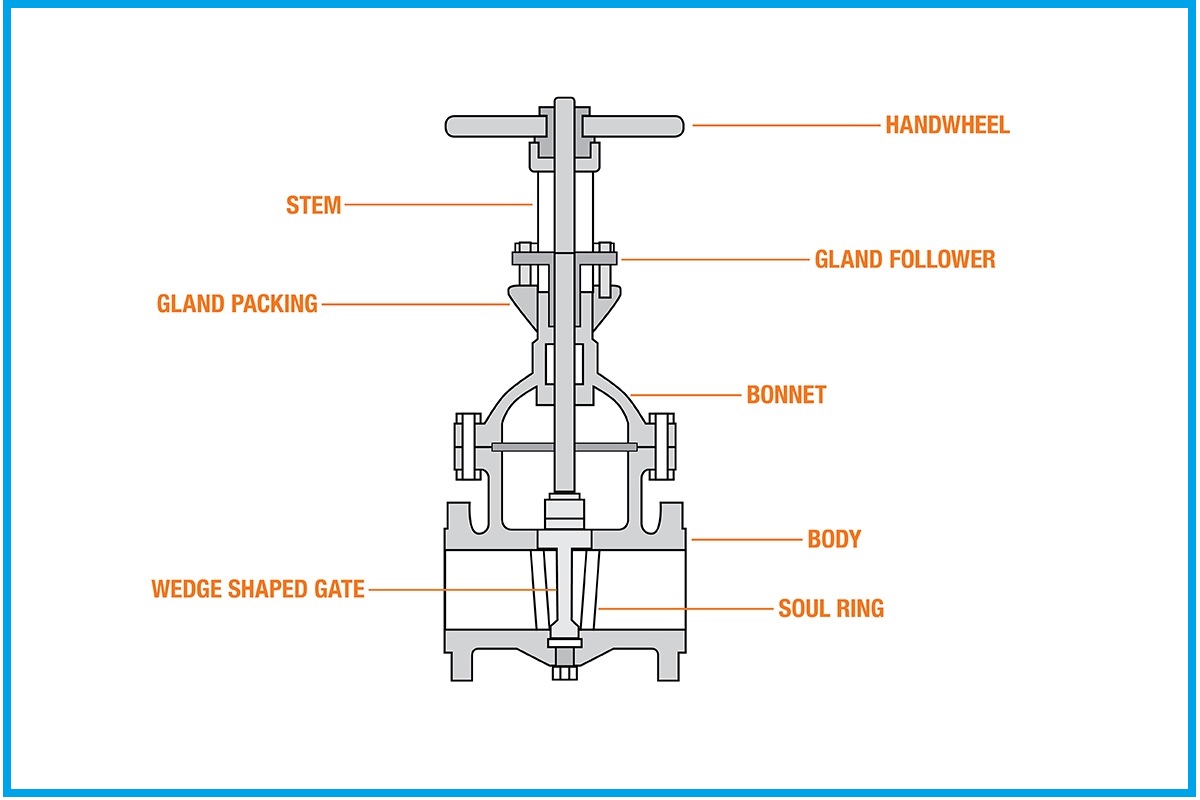

Gate Valve

-

Components: Includes valve body, gate/disc, valve seat, stem, and handwheel.

-

Operating Principle: When the handwheel is turned, the valve stem moves the gate up or down. Fully raising the gate allows fluid to flow freely through the pipeline; lowering it completely blocks the flow.

-

Advantages: Minimizes pressure loss, suitable for large pipeline systems with high flow rates.

-

Disadvantages: Slow opening and closing speed, not ideal for continuous flow regulation.

Globe Valve

Construction: Consists of a valve body, valve disc, valve seat, valve stem, and handwheel.

-

Operating Principle: Rotating the handwheel or handle causes the valve stem to move the disc up or down, thereby adjusting the flow area within the pipeline.

-

Advantages: Provides precise flow control and regulation, suitable for systems that require high-pressure handling.

-

Limitations: Compared to ball valves and gate valves, globe valves typically cause higher pressure loss due to their non-straight flow path design.

Industrial valves, with their wide variety of types and versatile applications, play an indispensable role in all modern piping systems. They contribute significantly to optimizing operational processes and improving efficiency across various industrial sectors. From controlling flow and regulating pressure to ensuring system safety, each type of valve delivers practical value, helping systems operate more reliably, durably, and efficiently.

Related articles:

We hope this article has provided you with valuable insights into industrial valves, making it easier for you to select and use the right products to optimize the performance and efficiency of your systems.

If you require in-depth consultation or are looking for high-quality industrial valve solutions that meet precise technical requirements, please contact Phuc Minh Engineering — a trusted importer and official distributor of industrial valves, measurement sensors, and control equipment, with over 18 years of experience in the Vietnamese market.

Phuc Minh Engineering is committed to providing:

-

On-site system surveys and assessments

-

Professional steam system design consultation, optimizing system operation

-

Energy-saving solutions for steam trap systems

-

SSOP solutions to optimize equipment management and operation

Get in touch with Phuc Minh Engineering for prompt, professional, and dedicated support!

Related News

What is a Globe Valve?

19/09/2025

Globe Valve is one of the most widely used types of industrial valves in piping systems, designed for shutting off, regulating, and controlling fluid flow. This valve is especially popular in steam systems thanks to its stable operation and excellent sealing performance. Currently, Phuc Minh is proud to be a trusted distributor of globe valves, offering customers competitive prices, a wide range of models and sizes, and a commitment to providing genuine, high-quality products.

Globe Valve – Phuc Minh Engineering

19/09/2025

Globe valve is one of the most common types of industrial valves, widely used to stop, regulate, and control the flow of liquids and gases in piping systems. In particular, globe valves are extensively applied in steam, hot oil, high-pressure compressed air, chemicals, and heavy industrial systems.

Industrial Valves for Food, Beverage, and Edible Oil | Phuc Minh

19/09/2025

Supplying high-quality stainless steel industrial valves for the food, beverage, and edible oil industries. Certified products with CO-CQ, competitive prices.

Industrial Valves for Chemical Plants, Oil Refineries, and Petroleum | Phuc Minh

17/09/2025

Phuc Minh Engineering – Trusted supplier of industrial valves for chemical plants, oil refineries, and petroleum systems. Genuine products with CO-CQ, competitive prices.

Applications of Industrial Valves in Steam and Boiler Systems | Phuc Minh Engineering

17/09/2025

The role of industrial valves in steam and boiler systems In factories using steam and boiler systems, safety control and energy efficiency are critical. Industrial valves play a vital role in:

.png)