5 Common Mistakes in Installing Steam Traps That Factories Often Encounter

5 Common Mistakes in Installing Steam Traps That Factories Often Encounter

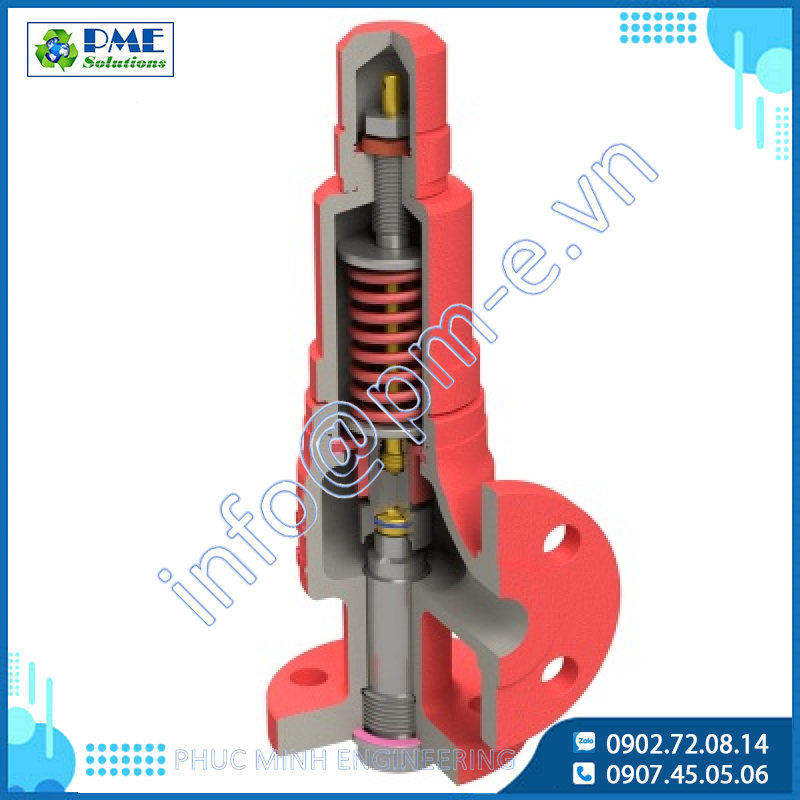

In industrial steam systems, the steam trap is a critical device that removes condensate and air while retaining live steam to maximize operational efficiency. However, many factories still experience steam loss, energy waste, or equipment damage due to improper installation of steam traps.

Here are the 5 most common mistakes that plant engineers and operators should avoid:

1. Choosing the Wrong Type of Steam Trap for the Application

Many factories select steam traps based on habit or by copying other systems, without considering actual factors such as flow rate, pressure, temperature, and the type of equipment using steam (e.g., heating, drying, heat exchangers).

Example mistake:

-

Using a float trap for a main steam line – not suitable because float traps cannot handle high condensate loads and pressure.

Recommendation:

-

Conduct a thorough system survey and select the correct trap: float, thermodynamic, inverted bucket, disc trap, etc., depending on the application.

2. Incorrect Installation Direction and Location

Steam traps are designed with a specific flow direction, but in reality, many factories install them backward or in improper positions. This causes the trap to malfunction or fail prematurely.

Signs of improper installation:

-

Trap does not discharge condensate, water accumulates, and abnormal pressure differences occur.

Recommendation:

-

Install traps in the correct flow direction and elevation.

-

Position them at the lowest point where condensate naturally collects.

3. Not Installing Accessories Such as Strainers and Bypass Valves

Some factories try to cut costs by skipping the installation of strainers, bypass valves, or isolation valves.

Consequences:

-

Dirt and debris clog the trap, preventing condensate discharge and reducing lifespan.

-

Maintenance becomes difficult, requiring a full system shutdown for replacement.

Recommendation:

-

Always install a strainer before the trap.

-

Install bypass and isolation valves for easy inspection and maintenance.

4. Using Too Few Traps or Grouping Multiple Condensate Points Into One Trap

Some technicians combine multiple condensate discharge points into one trap to save costs, leading to overload and ineffective condensate removal.

Consequences:

-

Water accumulation inside equipment causes rust, corrosion, and even water hammer risks.

Recommendation:

-

Install sufficient traps in appropriate locations.

-

Do not group multiple discharge points into a single trap unless carefully engineered.

5. No Regular Inspection and Replacement of Failed Steam Traps

Over time, steam traps can wear out, get stuck, or leak. Without inspection, live steam may continuously escape unnoticed.

Estimated losses:

-

A single failed trap can waste 10–50 kg of steam per hour, costing hundreds of millions VND per year.

Recommendation:

-

Plan routine inspections every 3–6 months.

-

Use inspection tools such as ultrasonic detectors or thermal sensors.

-

Replace faulty traps immediately to save energy.

Conclusion

Although small, steam traps play a major role in the efficiency and safety of a factory’s steam system. Incorrect selection, poor installation, or lack of maintenance can cause serious financial losses and safety risks.

👉 If you need free consultation on steam trap installation, inspection, or system optimization, please contact us.

Steam Trap Consultant & Supplier for Steam Systems – Phuc Minh

Phuc Minh Engineering Co., Ltd. specializes in supplying industrial valves and steam traps for steam systems and boilers in Vietnam. We are committed to:

-

Genuine products with full CO-CQ certification

-

Optimized solutions tailored for each factory

-

On-site technical support from experienced engineers

-

Fast delivery and competitive pricing

👉 Learn more about our products at: www.pm-e.vn

📍 Contact Information:

Phuc Minh Engineering Co., Ltd.

Address: 92/38, Street No. 12, Quarter 18, Binh Hung Hoa Ward, Ho Chi Minh City

Tel: +84 28 3535 2125 – Fax: +84 28 3535 0254

📲 Quotation via Zalo: 0902.720.814

📲 Technical support via Zalo: 0907.450.506

📧 Email: info@pm-e.vn

Related News

What is a Globe Valve?

19/09/2025

Globe Valve is one of the most widely used types of industrial valves in piping systems, designed for shutting off, regulating, and controlling fluid flow. This valve is especially popular in steam systems thanks to its stable operation and excellent sealing performance. Currently, Phuc Minh is proud to be a trusted distributor of globe valves, offering customers competitive prices, a wide range of models and sizes, and a commitment to providing genuine, high-quality products.

Globe Valve – Phuc Minh Engineering

19/09/2025

Globe valve is one of the most common types of industrial valves, widely used to stop, regulate, and control the flow of liquids and gases in piping systems. In particular, globe valves are extensively applied in steam, hot oil, high-pressure compressed air, chemicals, and heavy industrial systems.

Industrial Valves for Food, Beverage, and Edible Oil | Phuc Minh

19/09/2025

Supplying high-quality stainless steel industrial valves for the food, beverage, and edible oil industries. Certified products with CO-CQ, competitive prices.

Industrial Valves for Chemical Plants, Oil Refineries, and Petroleum | Phuc Minh

17/09/2025

Phuc Minh Engineering – Trusted supplier of industrial valves for chemical plants, oil refineries, and petroleum systems. Genuine products with CO-CQ, competitive prices.

Applications of Industrial Valves in Steam and Boiler Systems | Phuc Minh Engineering

17/09/2025

The role of industrial valves in steam and boiler systems In factories using steam and boiler systems, safety control and energy efficiency are critical. Industrial valves play a vital role in:

.png)