What is a Globe Valve?

Globe Valve is one of the most widely used types of industrial valves in piping systems, designed for shutting off, regulating, and controlling fluid flow. This valve is especially popular in steam systems thanks to its stable operation and excellent sealing performance. Currently, Phuc Minh is proud to be a trusted distributor of globe valves, offering customers competitive prices, a wide range of models and sizes, and a commitment to providing genuine, high-quality products.

What is a Globe Valve?

A globe valve, also known as a stop valve or steam valve, is an industrial device used to open/close or regulate fluid flow in pipelines. The name “globe valve” comes from the design of its disc, which is shaped similarly to a globe, allowing for precise flow control and enhanced leak prevention.

This is a type of linear control valve that allows users to adjust the degree of opening and closing at multiple levels, thereby determining how much liquid or gas flows through according to actual demand. Thanks to its flow-guiding design, the valve not only helps reduce system pressure but also enhances the circulation speed of the fluid.

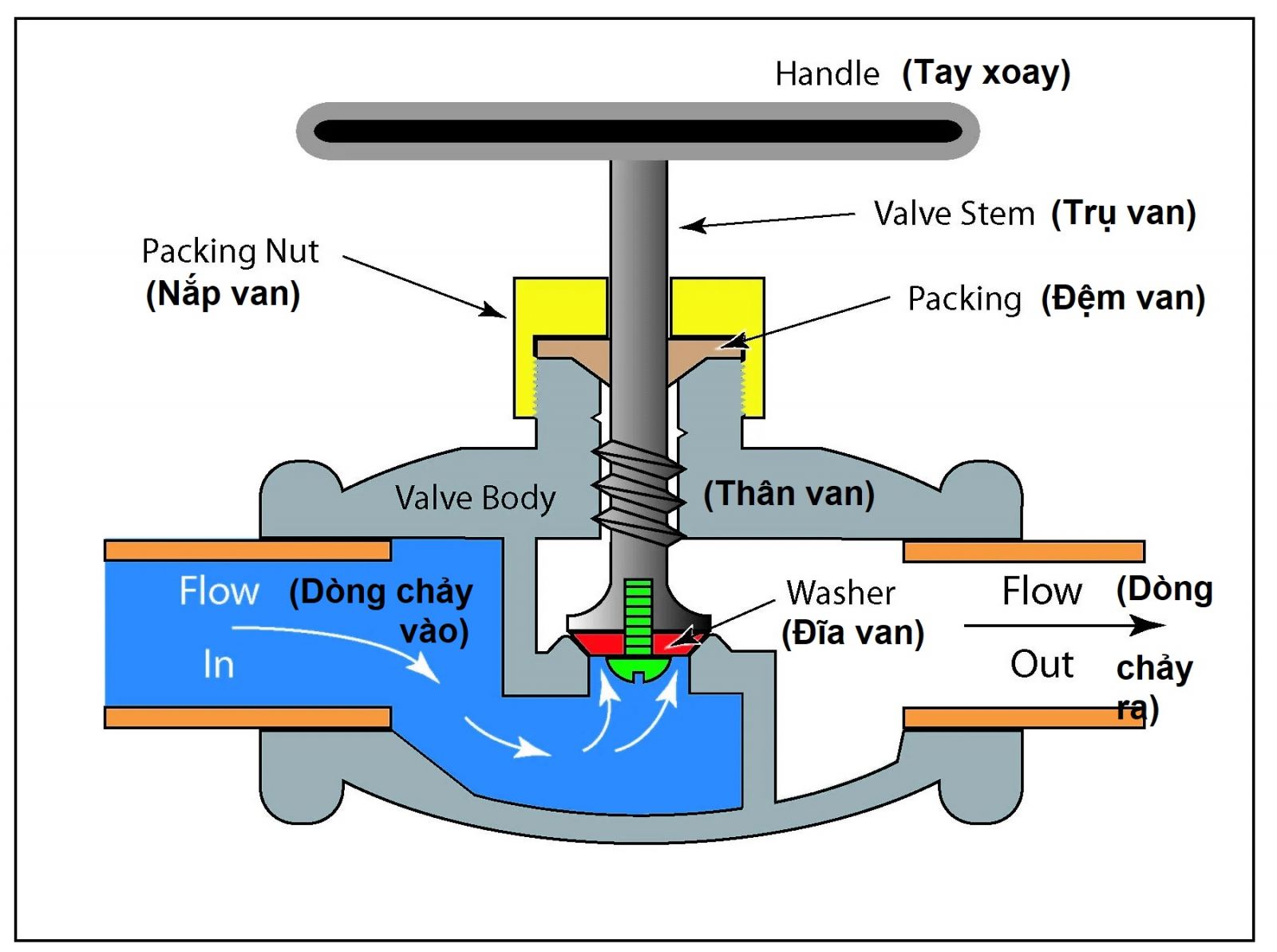

The internal structure of the globe valve is quite unique. The valve body is divided into two chambers by a partition: the lower chamber serves as the inlet and the upper chamber as the outlet. These two sections are connected by a circular opening in the partition, which allows the fluid to pass through when the valve is open.

Due to its flexible flow regulation capability, the globe valve is widely applied in many industrial systems, especially hot water pipelines, steam lines, high-pressure compressed air systems, hot oil circulation, and other environments that require precise flow control.

In terms of size, this type of valve is generally large. The most common size is DN400, but in large-scale systems or those with high technical requirements, the size can reach up to DN1200.

Technical Specifications of Globe Valves

Each type of Globe Valve may vary in design and features, but below are the basic technical specifications for reference:

-

Body Material: Stainless steel, cast iron, brass, carbon steel, plastic, heat-resistant and anti-corrosion alloys.

-

Main Components: Stem, body, bonnet, disc, actuator, sealing gasket.

-

Size Range: DN15 – DN1200.

-

Connection Types: Threaded, flanged, welded.

-

Operation Methods: Handwheel, electric actuator, pneumatic actuator.

-

Working Temperature: -20°C to 450°C.

-

Connection Standards: ANSI, DIN, BS, JIS, etc.

-

Application Media: Water, oil & gas, compressed air, steam, chemicals.

-

Pressure Rating: PN16 – PN25 (or higher depending on product line).

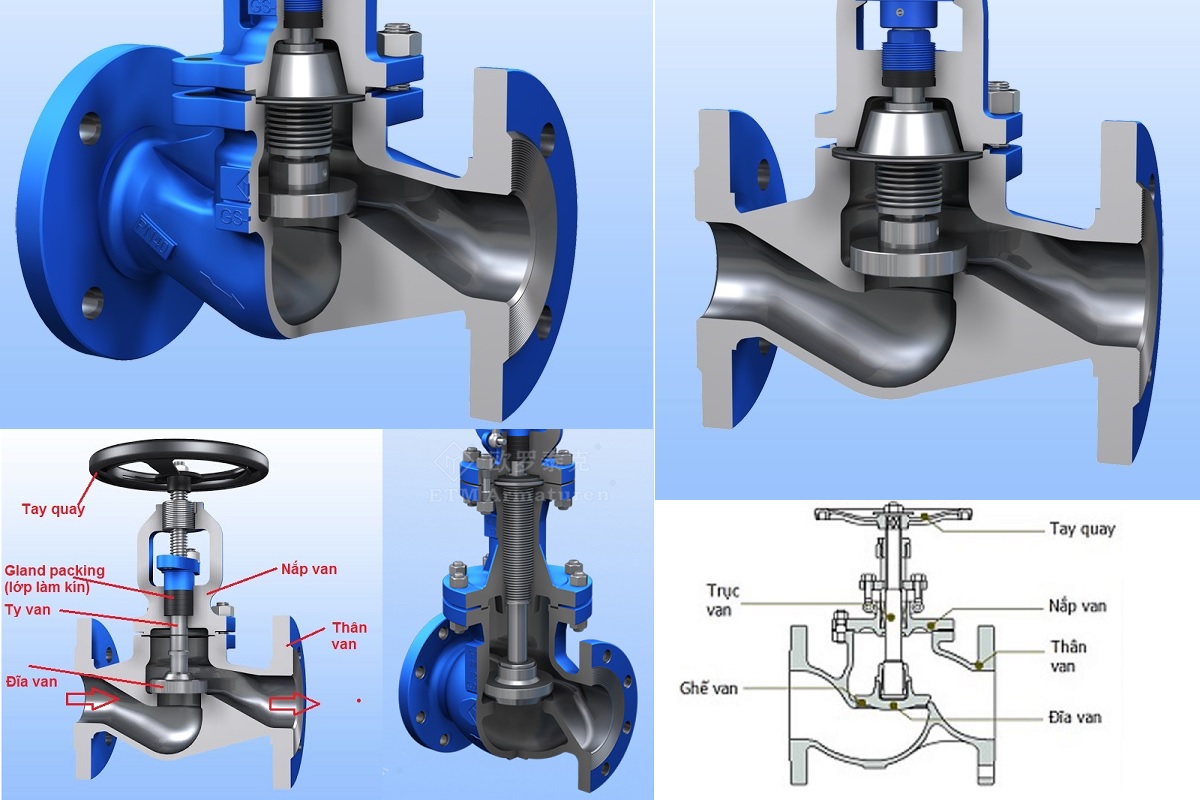

Basic Structure of a Globe Valve

Globe valves come in various models, shapes, and designs to meet different application requirements. However, to ensure stable and safe operation, a globe valve typically consists of the following main components:

Valve Body

The valve body is the most important part, serving as the main pressure-containing shell of the fluid and protecting all internal components. It also acts as the passage for the flow.

The body is usually made of stainless steel or plastic for corrosion resistance, and from steel or cast iron when used in high-temperature and high-pressure environments.

To enhance tightness, the valve seat is often equipped with an elastic sealing material (such as rubber). This helps minimize leakage when debris adheres to the valve seat surface, as the elastic layer can fill small gaps.

Port Types

-

Two-way globe valve: The most common type, used to direct and control flow in one direction.

-

Three-way globe valve: Less commonly used, typically applied in specialized systems where flow needs to be split into multiple directions or where different fluids need to be mixed.

Disc

The disc is a crucial component of the globe valve. It moves up and down under the action of the handwheel to open, close, or regulate the flow of fluid in the pipeline. Depending on the application, the globe valve disc can have various shapes such as conical or flat disc, ensuring suitability for different operating requirements.

The disc is typically made of hard alloys with excellent resistance to heat, pressure, and corrosion. Since it comes into direct contact with the fluid, the disc must possess high durability to ensure long service life.

Bonnet

The bonnet is the upper cover of the globe valve. It prevents fluid from leaking or backflowing during operation and enhances the structural strength of the valve when subjected to high pressure or high-velocity flow that may cause vibrations.

Additionally, the bonnet is designed for easy removal, allowing convenient installation of accessories, maintenance, or repair. It is usually made from the same material as the valve body and connected securely by bolts or threads.

Stem

The stem connects the handwheel to the disc, transmitting force and ensuring synchronized movement of the components. When the operator turns the handwheel, torque is transferred through the stem to the disc, thereby precisely opening or closing the valve.

Since it must withstand frequent mechanical force, the stem is typically made of durable hard alloys with high resistance to corrosion and elevated temperatures. One end of the stem is usually threaded for easy assembly with other components of the globe valve.

Actuator

Globe valves can be equipped with various types of actuators depending on operational requirements and investment levels. Common actuator types include:

-

Handwheel: manually operated, safe, easy to use, and low-cost.

-

Electric actuator: automates the opening and closing process, suitable for systems requiring remote operation, though it comes with higher investment and maintenance costs.

-

Pneumatic actuator: operates using air pressure, commonly applied in industrial environments that demand quick and precise opening and closing.

All these actuators are directly connected to the valve stem, transmitting torque to the disc to perform opening, closing, or throttling functions. In practice, the handwheel remains the most popular choice due to its simplicity, durability, and cost-effectiveness.

Sealing Gasket

The sealing gasket plays a crucial role in preventing fluid leakage to the outside, ensuring stable system operation. It is typically made from high-performance materials resistant to heat and high pressure, such as special rubber, PTFE, or graphite.

During operation, solid particles may accumulate on the bonnet or disc, creating gaps and reducing tightness. The gasket is designed to absorb and fill these gaps, maintaining optimal sealing performance.

To ensure reliable performance and prevent leakage, sealing gaskets should be inspected, maintained, and replaced periodically.

Để đảm bảo hiệu quả hoạt động và tránh rò rỉ, gioăng làm kín cần được kiểm tra, bảo dưỡng và thay thế định kỳ.

Operating Principle of the Globe Valve

The operating mechanism of a globe valve is quite similar to many other industrial valves, primarily relying on the coordination of three main components: the handwheel – valve stem – valve disc. The working principle can be explained in the following steps:

Closed Position: When the valve disc is positioned in the middle of the valve body, it forms a partition that divides the body into two separate chambers, completely blocking the flow of the fluid.

Opening the Valve: The operator turns the handwheel (clockwise or counterclockwise). This movement generates a torque acting on the valve stem, which transmits the force to the valve disc. As the disc moves away from the partition, a gap is created, allowing the fluid to flow freely. With its characteristic design, the globe valve not only regulates flow but also helps reduce pressure and increase the fluid velocity.

Closing the Valve: By turning the handwheel in the opposite direction, the valve stem pushes the disc down, gradually forming a barrier to block the fluid. Because the fluid pressure is usually high, this process requires a strong and steady force to ensure the disc fits tightly against the seat, maintaining a perfect seal and returning the valve to the closed position.

Common Types of Globe Valves Today

The industrial valve market is very diverse, with globe valves manufactured in various designs, materials, and price ranges. Choosing the right type depends on the actual requirements of the system and the investment budget. Below are the most commonly used globe valves, classified based on their connection methods:

1. Classification by Connection Type

Globe valves come with several connection types, with the three most common being: flanged globe valves, threaded globe valves, and welded globe valves. Each type has its own advantages, making it easier for users to select based on system design and intended use.

2. Flanged Globe Valve

-

Commonly used in large piping systems (DN50 and above).

-

Both ends of the valve are flanged, allowing easy direct installation onto the pipeline.

-

Common materials: stainless steel, steel, ductile iron, etc., providing high pressure resistance, corrosion protection, and suitability for high-temperature environments.

-

Flanges comply with international standards such as ANSI, JIS, BS, DIN, and are usually combined with sealing gaskets to prevent fluid leakage.

3. Threaded Globe Valve

-

Suitable for smaller pipelines (under DN50).

-

Most effective in medium to low-pressure environments (typically below PN16).

-

Made from a variety of materials: stainless steel, steel, copper, plastic, etc.

-

Can be used in specialized environments such as hot oil, compressed air, dilute acids, or low-corrosive solutions.

Welded Globe Valve

A welded globe valve is a type of valve that uses a fixed weld to directly connect the valve body to the pipeline. This connection method is typically applied in small-diameter piping systems that operate under high pressure (from 40 bar or more), where flanged connections cannot ensure a tight seal at such pressure levels.

The main advantage of the welded connection is its absolute sturdiness, which allows the valve to operate stably while minimizing the risk of leakage or cracking at the joint.

Typically, these valves are made from heat-resistant and pressure-resistant steel, making them suitable for harsh working environments such as high-pressure steam boilers, industrial pneumatic systems, or equipment operating at high temperatures.

Classification by structure

Based on their design, globe valves are divided into four main types: Tee (straight-through) globe valves, angle globe valves, Y-pattern globe valves, and ball-type globe valves.

Tee Globe Valve (saddle type)

This is the most common and widely used design today.

Operation mechanism: when the handwheel is turned, the valve disc moves vertically, perpendicular to the flow within the pipe.

Advantages: it can withstand high flow pressures, reduces pressure drop, and is highly effective in regulating and controlling flow.

Because of these benefits, Tee globe valves are often the top choice in many industrial systems that require stability and safety.

Y-Pattern Globe Valve

This type of valve is particularly valued for minimizing pressure drop, thanks to its stem and body being inclined at approximately 45° relative to the flow direction. This design reduces flow resistance to a minimum while also limiting wear during operation.

The Y-pattern globe valve is especially suitable for systems requiring stable pressure and flow. However, compared to other types, it occupies more installation space and typically involves higher investment costs than a Tee (straight-through) globe valve.

Ball-Type Globe Valve

Ball-type globe valves are commonly used in medium- and small-diameter piping systems, with two main connection types: threaded and flanged.

They are usually made from durable materials such as stainless steel, cast iron, bronze, or steel, making them suitable for harsh operating conditions, including clean water, wastewater, compressed air, steam, chemicals, corrosive solutions, and high-pressure or high-temperature environments.

Advantages of ball-type globe valves include a wide range of sizes and designs, ease of installation, removal, and maintenance, and relatively reasonable pricing compared to many other globe valve types.

Angle Globe Valve

Unlike conventional globe valves, angle globe valves feature a special design with the inlet and outlet ports positioned at a 90° angle, allowing the flow to change direction within the valve body. This reduces flow pressure significantly, making it ideal for systems that require directional changes in fluid flow.

However, due to their unique design, angle globe valves are less common, often harder to install within systems, and generally have higher costs compared to standard globe valves.

Classification by Operation Method

In addition to manual handwheel operation, globe valves today are also available with electric or pneumatic actuators to meet industrial automation needs.

Handwheel-Operated Globe Valve

This is the traditional and most widely used operation method across various systems. The operator simply turns the handwheel, transmitting torque to the valve stem, which moves the disc up or down to open, close, or regulate flow as required.

The advantages of this method are its simple construction, ease of operation, low cost, and convenience for installation, maintenance, and repair. For these reasons, handwheel-operated globe valves remain the preferred choice in many practical applications.

Electric Actuated Globe Valve

Unlike manual operation, electric control offers a high level of automation, improving operational efficiency and reducing human labor.

This type of valve operates using an electric motor, which transmits force to the valve stem to open or close the valve disc. The power supply can be 24V, 220V, or 380V, depending on the system.

A major advantage of electric globe valves is remote control. With just a button or switch, the operator can simultaneously control multiple devices in a production line, saving significant time and effort.

Additionally, for hazardous, high-up, or hard-to-reach locations, electrically actuated globe valves are an ideal choice. However, this type of valve is relatively expensive and is typically suitable for modern systems with a high degree of automation.

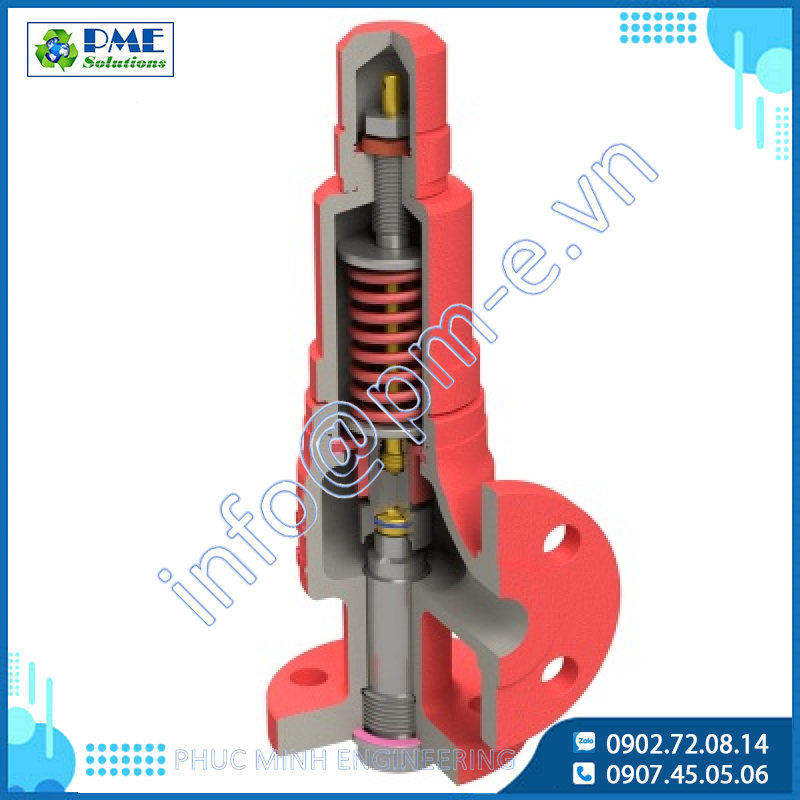

Pneumatic Actuated Globe Valve

Pneumatic globe valves are operated by an actuator using compressed air. When air is supplied, the cylinder generates force on the valve stem, moving the disc up or down to open or close the flow.

This type of valve is notable for safety, fast operation, ease of maintenance, and lower investment cost compared to electric valves. Therefore, pneumatic globe valves are commonly used in steam systems, fluid pipelines, or production lines requiring rapid opening and closing.

Material Classification

Globe valves are manufactured from various materials to meet diverse operational needs and budget requirements.

Stainless Steel Globe Valve

Primarily made from stainless steel 304 or 316, this type of valve is the most expensive among all materials but offers exceptional durability and performance.

Key advantages of stainless steel include corrosion resistance, high temperature and pressure tolerance, chemical resistance, and protection against oxidation in outdoor environments. As a result, stainless steel globe valves have a long service life and maintain stable operation over extended periods.

Cast Iron Globe Valve

Cast iron globe valves are usually made from ductile iron or solid cast iron. This type of valve is popular in the market due to its reasonable price and ease of use. However, its pressure and temperature resistance are only moderate, so it is typically applied in ordinary water or steam systems. With proper periodic maintenance, cast iron globe valves can still operate reliably and have a long service life.

Bronze Globe Valve

Bronze globe valves are generally compact in size, have good heat resistance, and are commonly used in residential systems. However, their limitation lies in corrosion resistance, making them suitable only for domestic water systems or low- to medium-pressure gas lines.

Advantages and Disadvantages of Globe Valves

Globe valves are considered essential and highly valuable in many industrial sectors due to their outstanding features:

Advantages:

-

Highly effective in stopping, regulating, and controlling fluid flow, regarded as one of the most reliable valve types.

-

Available in various materials (stainless steel, cast iron, bronze, plastic, steel, etc.) and designs, suitable for diverse systems and budgets.

-

Easy to install, remove, maintain, and repair.

-

Can operate well in harsh environments: high temperature, high pressure, and certain materials resistant to chemicals and outdoor oxidation.

-

Quick opening/closing, easy operation, minimizing fluid leakage.

-

Valve disc has strong corrosion resistance, particularly effective in flow control positions.

-

Supports multiple control methods: manual handwheel, electric, or pneumatic automation.

Disadvantages:

-

Depending on the material, some valves have limited corrosion and pressure resistance.

-

Investment cost varies significantly among materials (e.g., stainless steel is much more expensive than cast iron or bronze).

Although globe valves offer many advantages, they also have some limitations that customers should consider before choosing:

-

For large-sized valves, opening and closing can be difficult due to strong flow pressure acting on the valve disc.

-

The outlet pressure often drops significantly compared to the inlet.

-

Pressure drop is higher than that of gate valves.

-

Heavier in weight compared to other valves of the same size and material.

-

The cost is generally higher than other industrial valves.

Applications of Globe Valves

Thanks to their effective flow regulation and control capabilities, globe valves are widely used across various industrial sectors, especially in steam and water systems. Typical applications include:

-

Used in industrial production lines, particularly in locations requiring throttling and flow adjustment.

-

Applied in the extraction, processing, and transport of fuels such as oil and gas.

-

Utilized in the chemical industry due to their tight sealing, minimizing chemical leakage.

-

Installed in water cooling systems.

-

Used for pumps, compressors, and other pressure equipment.

-

Applied in venting, condensation, and vent drainage systems.

-

Commonly found in water supply and drainage sectors as well as industrial piping systems.

Some Notes When Choosing a Globe Valve

To ensure stable and long-lasting system operation, selecting the right type of globe valve is extremely important. The appropriate choice guarantees safety, optimizes performance, and extends the equipment’s lifespan. Key considerations include:

Based on working conditions:

-

Chemical environments → choose a plastic globe valve.

-

High temperature/pressure environments → choose a steel globe valve.

-

Systems with corrosive substances → choose a stainless steel globe valve.

-

Standard applications → choose a cast iron globe valve.

Based on size:

Select a valve according to the pipe diameter and system scale to ensure safe and efficient operation.

Based on origin:

Currently, the market offers many imported valves from countries such as South Korea, Japan, Malaysia, China, and Europe. Users can choose based on technical requirements and budget.

Globe Valve Maintenance Guide

To ensure the globe valve operates efficiently and has a long service life, regular maintenance is essential. Basic maintenance steps include:

-

Regularly inspect and service the valve to detect any faults or damage early.

-

Check the connection between the valve body and the pipeline for leaks or corrosion.

-

Verify the smooth operation of the handwheel.

-

Tighten bolts and nuts, and lubricate components to prevent rust and oxidation.

-

When removing the valve for inspection, the entire system must be shut down first. Failure to do so could result in high-pressure damage, posing a risk to the operator.

It can be affirmed that the globe valve is currently one of the most important industrial devices, widely applied across various sectors, and particularly prominent in steam systems. The product comes in a variety of designs, materials, and price ranges, allowing customers to easily choose according to their specific needs and investment budget.

Contact Information

If you need more detailed information about globe valves or wish to purchase genuine, high-quality products at competitive prices, please contact Phuc Minh Company via hotline: 0902 720 814 – 0907 450 506 – 0902 800 728 for dedicated consultation and prompt support.

📍 Phuc Minh Engineering Co., Ltd

Address: 92/38 Street No. 12, KP18, Binh Hung Hoa Ward, Ho Chi Minh City

Tel: 028.3535.2125 – Fax: 028.3535.0254

📲 Zalo Price Support: 0902.720.814

📲 Zalo Technical Support: 0907.450.506 or 0902.800.728

🌐 Website: www.pm-e.vn

Related News

Globe Valve – Phuc Minh Engineering

19/09/2025

Globe valve is one of the most common types of industrial valves, widely used to stop, regulate, and control the flow of liquids and gases in piping systems. In particular, globe valves are extensively applied in steam, hot oil, high-pressure compressed air, chemicals, and heavy industrial systems.

Industrial Valves for Food, Beverage, and Edible Oil | Phuc Minh

19/09/2025

Supplying high-quality stainless steel industrial valves for the food, beverage, and edible oil industries. Certified products with CO-CQ, competitive prices.

Industrial Valves for Chemical Plants, Oil Refineries, and Petroleum | Phuc Minh

17/09/2025

Phuc Minh Engineering – Trusted supplier of industrial valves for chemical plants, oil refineries, and petroleum systems. Genuine products with CO-CQ, competitive prices.

Applications of Industrial Valves in Steam and Boiler Systems | Phuc Minh Engineering

17/09/2025

The role of industrial valves in steam and boiler systems In factories using steam and boiler systems, safety control and energy efficiency are critical. Industrial valves play a vital role in:

Industrial Valves – Effective Flow Control Solutions | Phuc Minh Engineering Co., Ltd.

17/09/2025

What is an industrial valve? Industrial valves are essential mechanical devices in piping systems, responsible for regulating, opening/closing, and controlling the flow and pressure of liquids, gases, or steam. They are widely applied in many industries:

.png)