Comprehensive Valve and Process Control Solutions for Key Industries

Comprehensive Valve and Process Control Solutions for Key Industries

1. Water Treatment Industry – Scale and Challenges

Water treatment is a vital sector, ensuring safe water supply for both residential and industrial use. As urbanization and industrialization accelerate, water treatment systems must meet increasingly stringent requirements:

-

Ensure output water quality meets national and international standards.

-

Maintain continuous, stable operation while minimizing unexpected downtime.

-

Optimize energy efficiency and reduce operational and maintenance costs.

-

Integrate monitoring and automation for enhanced remote control and management.

-

Comply with strict environmental protection regulations and carbon emission reduction goals.

Recommended Solutions: Specialized industrial valves, sensors, and process control devices supplied by Phuc Minh Engineering, tailored to meet the complex demands of modern water treatment plants.

2. Textile Dyeing Industry – Valve and Process Control Solutions

The textile dyeing industry is a key manufacturing sector facing specific challenges:

-

High energy consumption in heating, washing, dyeing, and drying processes.

-

Precise temperature and pressure control to ensure fabric quality.

-

Reliable system operation in harsh industrial environments.

-

Standard-compliant wastewater treatment to protect the environment.

Phuc Minh Valve Solutions: High-temperature, high-pressure resistant valves, precision control equipment, and automated systems designed to improve energy efficiency and system stability.

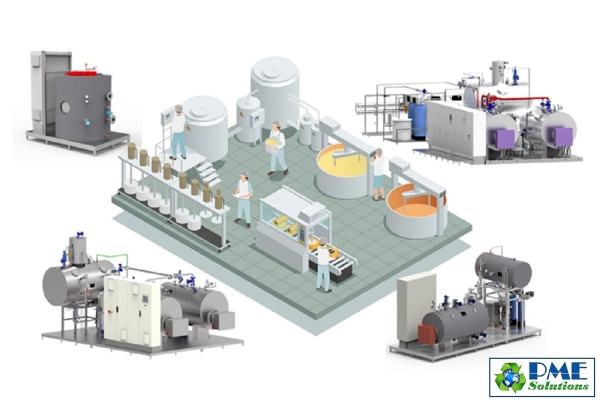

3. Instant Noodle Manufacturing Industry – Optimal Control Solutions

The instant noodle production industry requires continuous operation with strict food safety and process control standards:

-

Precise control of temperature and pressure in steaming, frying, and seasoning processes.

-

Optimization of steam and frying oil usage to reduce operating costs.

-

Ensuring system stability and accuracy in heat exchange and steam distribution.

-

Guaranteeing operational safety and minimizing pressure and temperature-related incidents.

Phuc Minh Offers:

-

Steam valves, pressure valves, and high-quality flow and pressure measurement devices.

-

Automated control solutions for continuous, stable production lines.

4. Chemical Industry – Specialized Solutions for Harsh Environments

The chemical industry operates in highly corrosive and hazardous conditions, requiring:

-

Accurate flow and level control of chemicals in tanks and pipelines.

-

Safe operation with minimal risk of chemical leaks.

-

High corrosion resistance to ensure equipment durability.

-

Advanced automation for monitoring and controlling processes safely and efficiently.

Phuc Minh’s Solutions: Corrosion-resistant specialty valves, liquid level sensors, and fully automated chemical flow and level control systems.

5. Fire Protection Systems (Fire Fighting) – High-Quality Valves

Phuc Minh Engineering supplies a wide range of UL/FM-certified fire protection valves, including:

-

Gate valves, butterfly valves, globe valves, angle valves, check valves, ball valves, and sprinkler heads.

-

High durability and reliability for commercial buildings, residential projects, industrial plants, and oil & gas facilities.

-

Compliance with international standards for fire protection systems.

6. HVAC Systems (Heating, Ventilation, Air Conditioning) – Complete Solutions

Phuc Minh provides high-quality HVAC products and solutions designed to optimize temperature, humidity, and air quality while saving energy:

-

Mechanical Valves: Butterfly valves, ball valves, gate valves, check valves made from stainless steel and ductile iron for durability and high performance.

-

Control Valves: Pneumatic and electric actuators for precise flow and pressure regulation.

-

Flow Meters: For accurate water and gas flow monitoring.

-

Pressure and Temperature Gauges: For system monitoring, adjustment, and safety.

Sourced from leading international brands: VYC (Spain), Nacional (Spain), Ritag (Germany), KSPC (Korea), Yamamoto (Japan), Conval (USA), OCV (USA), Boscarol (Italy), Kunkle (USA), Gasso (Spain), etc.

Phuc Minh Engineering is committed to providing optimal, energy-efficient HVAC solutions for all projects.

Related News

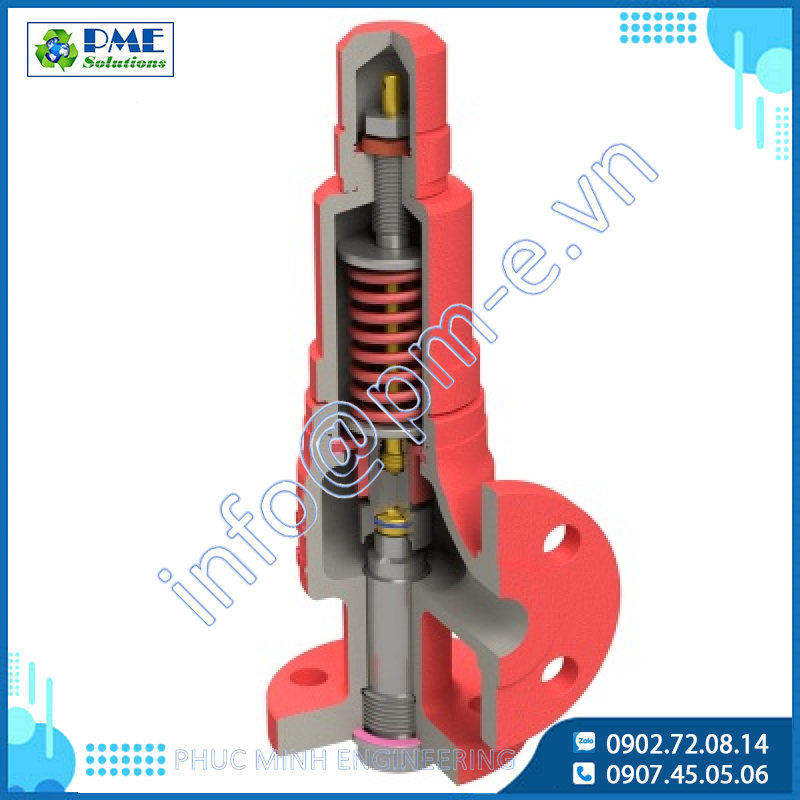

What is a Globe Valve?

19/09/2025

Globe Valve is one of the most widely used types of industrial valves in piping systems, designed for shutting off, regulating, and controlling fluid flow. This valve is especially popular in steam systems thanks to its stable operation and excellent sealing performance. Currently, Phuc Minh is proud to be a trusted distributor of globe valves, offering customers competitive prices, a wide range of models and sizes, and a commitment to providing genuine, high-quality products.

Globe Valve – Phuc Minh Engineering

19/09/2025

Globe valve is one of the most common types of industrial valves, widely used to stop, regulate, and control the flow of liquids and gases in piping systems. In particular, globe valves are extensively applied in steam, hot oil, high-pressure compressed air, chemicals, and heavy industrial systems.

Industrial Valves for Food, Beverage, and Edible Oil | Phuc Minh

19/09/2025

Supplying high-quality stainless steel industrial valves for the food, beverage, and edible oil industries. Certified products with CO-CQ, competitive prices.

Industrial Valves for Chemical Plants, Oil Refineries, and Petroleum | Phuc Minh

17/09/2025

Phuc Minh Engineering – Trusted supplier of industrial valves for chemical plants, oil refineries, and petroleum systems. Genuine products with CO-CQ, competitive prices.

Applications of Industrial Valves in Steam and Boiler Systems | Phuc Minh Engineering

17/09/2025

The role of industrial valves in steam and boiler systems In factories using steam and boiler systems, safety control and energy efficiency are critical. Industrial valves play a vital role in:

.png)