Korea Industrial Valve?

What Is an Industrial Valve? Classification, Applications, and Operating Principles – Phuc Minh Engineering

Industrial valves play a crucial role in ensuring the smooth operation of modern pipeline systems, from large-scale manufacturing plants to daily water supply systems. They help control flow, regulate pressure, and protect equipment, contributing to safe and efficient system operation.

In this article, Phuc Minh Engineering—a leading distributor of genuine industrial valves in Vietnam—will help you better understand industrial valves: their definition, classification, operating principles, and real-world applications.

What Is an Industrial Valve?

An industrial valve is a mechanical device installed in pipelines to control the flow of fluids. Fluids can include liquids (water, oil, chemicals), gases (compressed air, gas), or even slurry and powder.

Main Functions of Industrial Valves:

-

Fully open/close fluid flow

-

Regulate fluid flow rate

-

Adjust system pressure, protect equipment

-

Switch flow direction

-

Prevent incidents such as overpressure or backflow

Phuc Minh Engineering offers expert consultation on selecting the right valve to optimize system efficiency, reduce operating costs, and extend equipment lifespan.

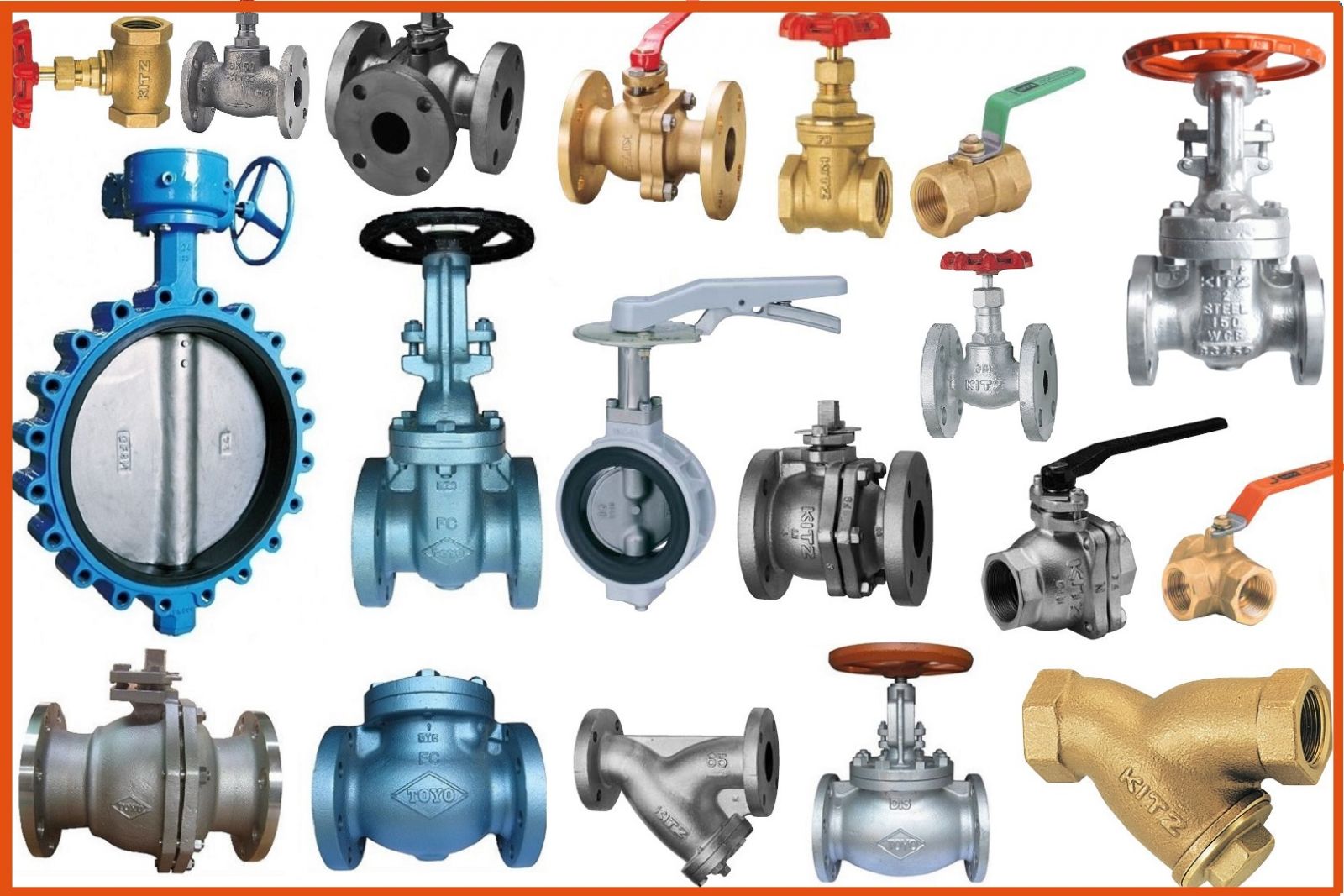

Classification of Industrial Valves

By Function:

-

Shut-off valves: Ball valves, gate valves, butterfly valves, globe valves, knife gate valves

-

Flow control valves: Needle valves, angle valves

-

Safety valves: Safety valves, pressure reducing valves, relief valves, check valves

-

Special valves: Strainers, drain valves

By Structure:

-

Ball Valve: Uses a perforated ball to open/close flow

-

Butterfly Valve: Uses a rotating disc to regulate flow

-

Gate Valve: Uses a sliding gate to control flow

-

Globe Valve, Needle Valve, Diaphragm Valve, Disc Valve

By Material:

-

Stainless Steel Valves (304, 316, 316L): Corrosion-resistant, for food, pharmaceuticals, chemicals

-

Steel Valves: High durability, for oil & gas, heavy industries

-

Brass Valves: Corrosion-resistant, used in HVAC, compressed air

-

Plastic Valves (PVC, UPVC, CPVC): Lightweight, chemical-resistant, affordable

By Operation Method:

-

Manual Valves: Hand lever, handwheel

-

Automatic Valves: Electric, pneumatic, hydraulic actuators

Phuc Minh Engineering supplies a full range of industrial valves from trusted brands such as Kitz, Toyo, Samwoo, Wonil, Genebre, and Ayvaz.

Real-World Applications of Industrial Valves

-

Water Industry: Water supply, wastewater treatment, irrigation

-

Oil & Gas: Extraction, transportation, processing

-

Food Industry: Processing, packaging, manufacturing

-

Chemical Industry: Production, mixing, transportation

-

Fire Protection Systems: Water supply, alarm systems

-

HVAC Systems: Air conditioning, ventilation

-

Other Industries: Pharmaceuticals, cement, paper, textiles

Phuc Minh Engineering provides on-site surveys, technical consultation, and valve supply tailored to your specific factory or project requirements.

Basic Operating Principles of Popular Valves

-

Ball Valve: Rotates a perforated ball to open/close flow

-

Butterfly Valve: Rotates a disc to adjust flow area

-

Gate Valve: Raises/lowers a gate to allow or block flow

-

Globe Valve: Moves a disc up/down to precisely regulate flow

Why Choose Industrial Valves from Phuc Minh Engineering?

✅ 100% genuine products from Japan, Korea, Europe

✅ Competitive prices, official warranty

✅ Full CO/CQ certificates

✅ Professional and experienced technical team

✅ Nationwide delivery, installation support

Contact Phuc Minh Engineering for Consultation and Pricing

If you need advice on choosing the right industrial valve, accurate pricing, and optimal solutions for your system, please contact:

-

Phuc Minh Engineering Co., Ltd

-

Hotline: 090.28.007.28 - 0902.72.08.14 - 0907.45.05.06

-

Tel: 028.3535.2125

-

Fax: 028.3535.0254

-

Website: www.pm-e.vn

-

Email: info@pm-e.vn

Phuc Minh Engineering is committed to delivering comprehensive, high-quality, and reasonably priced industrial valve solutions for all industries.

Related News

VinVal Industrial Water Valves: Stainless Steel Globe Valves & Pipeline Solutions from PM-E

20/12/2025

Discover high-quality VinVal industrial water valves. PM-E specializes in providing stainless steel globe valves and diverse fluid control solutions for your pipeline systems.

Steam Energy-Saving Solutions for Factories | Phuc Minh Engineering

17/12/2025

Optimize your steam system with Phuc Minh Engineering. Reduce energy loss, increase boiler efficiency, and cut fuel costs by 10–30%. Contact us now.

Flow Measurement & Pressure Control Solutions.

17/12/2025

Solutions for measuring flow and controlling pressure in steam, air, water, oil, and chemical systems. Optimize operations – reduce losses – enhance safety. Contact Phuc Minh.

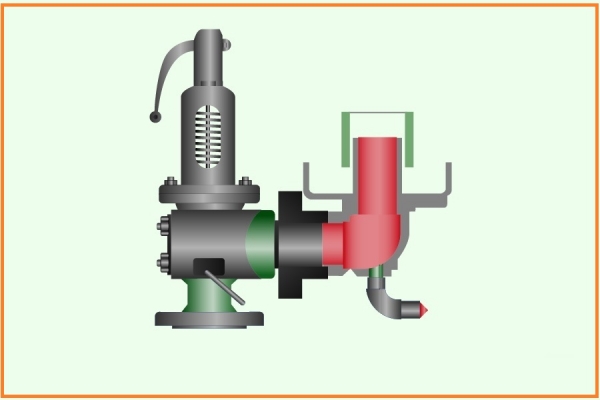

What Is a Pressure Reducing Valve? Structure – Working Principle – How to Select the Best PRV for Industrial Plants (2025)

17/12/2025

A Pressure Reducing Valve (PRV) is a device used to reduce high inlet pressure to a stable, lower outlet pressure, helping protect piping systems, instruments, and machinery while improving operational safety. PRVs are widely used in: Steam systems Compressed air, gas, nitrogen Clean water – process water – chilled water Oil, chemicals, and other industrial media

Safety Valve For Steam Systems: Structure, Operation Principles & Selection Guide 2025 | Phuc Minh Engineering

17/12/2025

Learn what a steam safety valve is, how it works, different types, and how to select the correct valve for boilers and pipelines. EN/ASME-standard valves from Phuc Minh Engineering.

.png)