Industrial Valves – Effective Flow Control Solutions | Phuc Minh Engineering Co., Ltd.

Industrial Valves – Effective Flow Control Solutions | Phuc Minh Engineering Co., Ltd.

What is an industrial valve?

Industrial valves are essential mechanical devices in piping systems, responsible for regulating, opening/closing, and controlling the flow and pressure of liquids, gases, or steam. They are widely applied in many industries:

-

Chemical plants, refineries, oil & gas

-

Steam systems, boilers, heaters

-

Food, beverage, cooking oil, palm oil

-

Water treatment, HVAC, heavy industry

Common types of industrial valves

At Phuc Minh Engineering Co., Ltd., we supply a wide range of genuine industrial valves to meet all production requirements:

1. Globe Valve

-

Accurate flow regulation

-

High temperature and pressure resistance

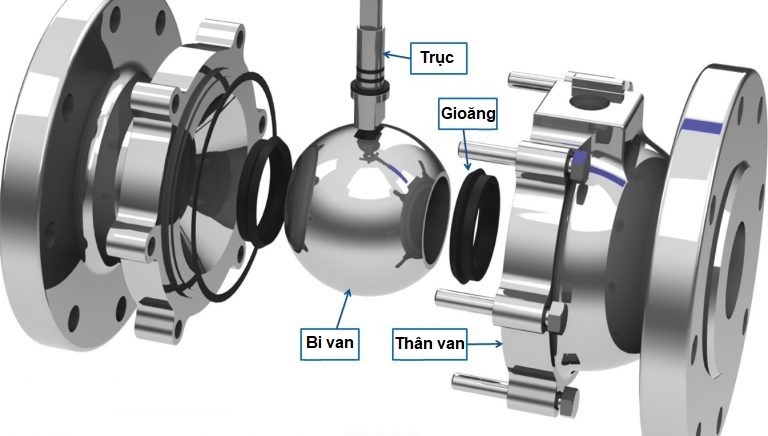

2. Ball Valve

-

Quick open/close

-

High tightness, easy maintenance

.jpg)

3. Gate Valve

-

Suitable for large pipeline systems

-

Ideal for liquids, steam, oil

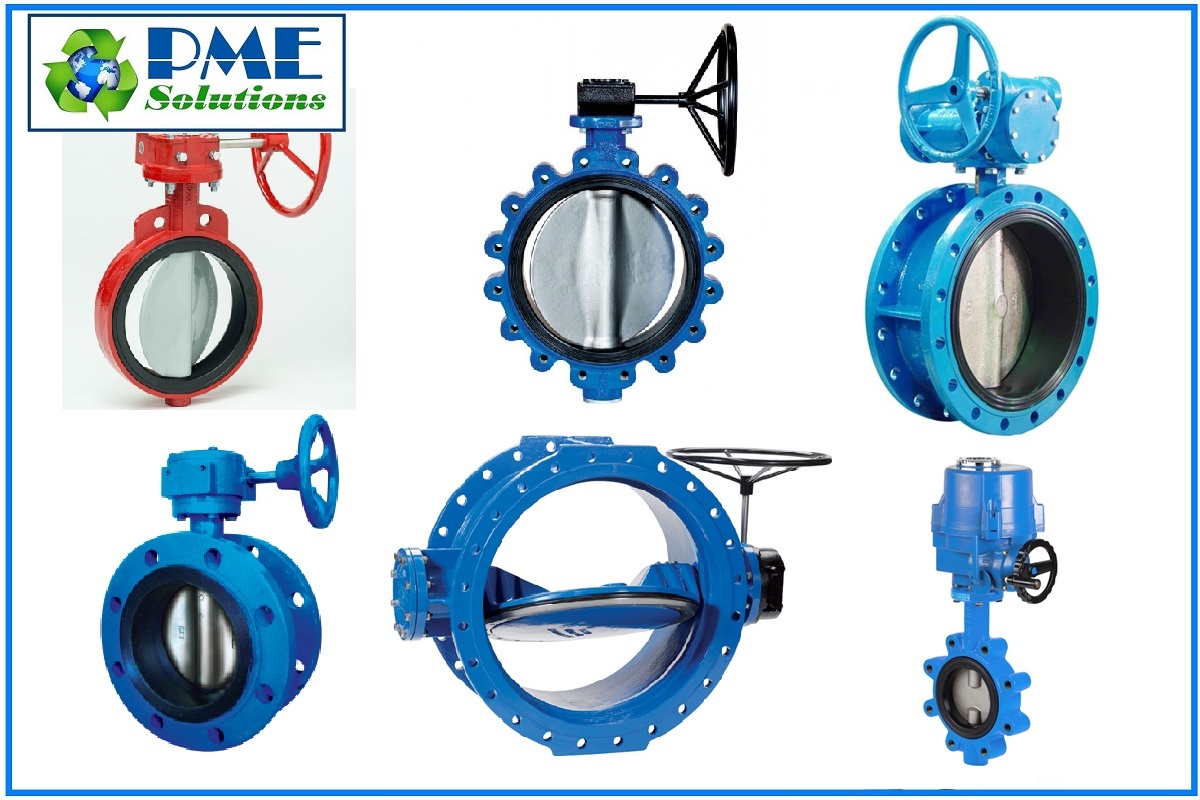

4. Butterfly Valve

-

Lightweight, space-saving

-

Cost-effective, easy to operate

5. Check Valve

-

Prevents backflow

-

Protects pumps and piping systems

.jpg)

6. Safety Valve

-

Protects system equipment and pipelines under preset pressure

-

Prevents pipe/device rupture due to overpressure, extends system and equipment lifespan

.jpg)

7. Breather Valve

-

Protect fuel and chemical storage tanks from overpressure and vacuum,...

-

Prevent tank rupture, explosion, or deformation...

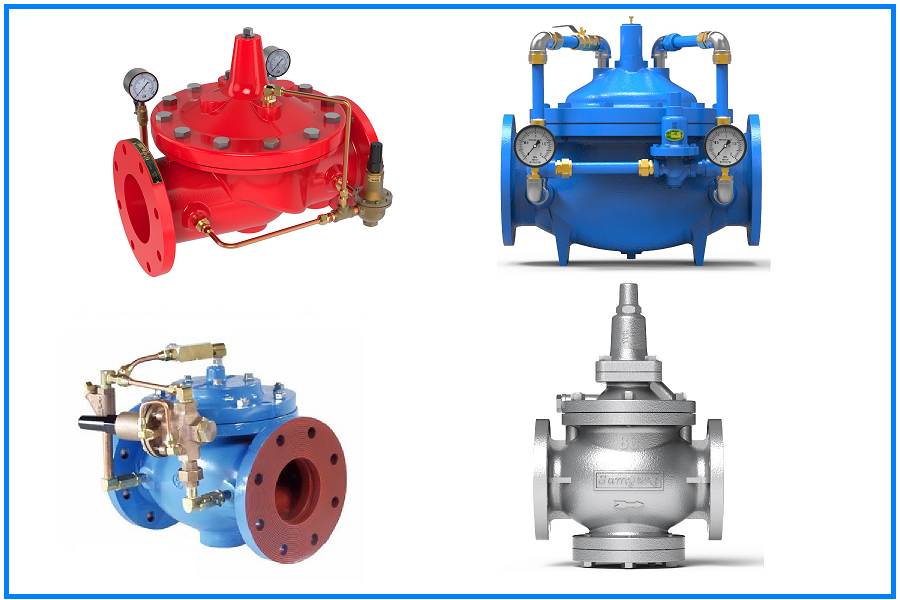

8. Pressure Reducing Valve

-

Maintains stable pressure

-

Prevents incidents, increases system lifespan

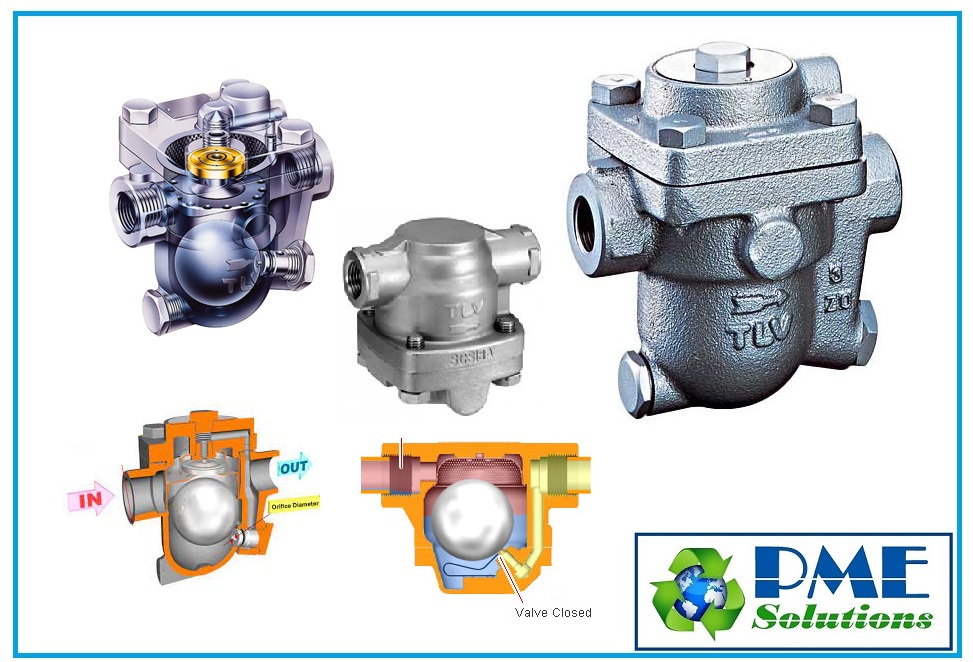

9. Steam Trap

-

Discharges air & condensate in steam systems

-

Helps maintain stable steam system temperature

👉 See more product details at: www.pm-e.vn

Why choose Phuc Minh Engineering Co., Ltd.?

✅ Trusted industrial valve supplier since 2017

✅ Genuine products with full certificates (CO, CQ)

✅ Experienced engineers provide on-site consultation

✅ 24/7 technical support via Zalo

✅ Competitive prices, fast nationwide delivery

Practical applications of Phuc Minh industrial valves

🔹 Steam systems in thermal power plants, textile, paper mills

🔹 Pipelines for oil & gas, chemicals, LPG, compressed air, cooking oil, palm oil...

🔹 Food, beverage, cooking oil, brewery production lines...

🔹 Chemical plants, wastewater treatment, refineries...

Contact Information

For the best quotation and consultation on suitable industrial valves, please contact:

📍 Phuc Minh Engineering Co., Ltd.

Address: 92/38 Street No.12, KP18, Binh Hung Hoa Ward, HCMC

Tel: 028.3535.2125 – Fax: 028.3535.0254

📲 Zalo for pricing support: 0902.720.814

📲 Zalo for technical support: 0907.450.506

🌐 Website: www.pm-e.vn

Related News

inVal Industrial Valves: Stainless Steel Gate Valve Solution for Chemicals

20/12/2025

Discover VinVal industrial valve lines, especially specialized stainless steel gate valves. Learn how to select the most effective valve for corrosive chemicals

VinVal Industrial Water Valves: Stainless Steel Globe Valves & Pipeline Solutions from PM-E

20/12/2025

Discover high-quality VinVal industrial water valves. PM-E specializes in providing stainless steel globe valves and diverse fluid control solutions for your pipeline systems.

Steam Energy-Saving Solutions for Factories | Phuc Minh Engineering

17/12/2025

Optimize your steam system with Phuc Minh Engineering. Reduce energy loss, increase boiler efficiency, and cut fuel costs by 10–30%. Contact us now.

Flow Measurement & Pressure Control Solutions.

17/12/2025

Solutions for measuring flow and controlling pressure in steam, air, water, oil, and chemical systems. Optimize operations – reduce losses – enhance safety. Contact Phuc Minh.

What Is a Pressure Reducing Valve? Structure – Working Principle – How to Select the Best PRV for Industrial Plants (2025)

17/12/2025

A Pressure Reducing Valve (PRV) is a device used to reduce high inlet pressure to a stable, lower outlet pressure, helping protect piping systems, instruments, and machinery while improving operational safety. PRVs are widely used in: Steam systems Compressed air, gas, nitrogen Clean water – process water – chilled water Oil, chemicals, and other industrial media

.png)