inVal Industrial Valves: Stainless Steel Gate Valve Solution for Chemicals

In modern manufacturing plants, especially in the chemical, textile dyeing, or wastewater treatment industries, pipeline systems always face harsh challenges. Industrial valves are not merely open/close devices, but are "shields" protecting the safety of the entire operating process.

This article will introduce the VinVal brand in detail and deeply analyze common chemicals to help you choose the most suitable valve used for chemicals, especially the stainless steel gate valve line.

I. Introduction to the VinVal Brand

In the current industrial equipment market, VinVal has asserted its position as one of the reputable flow control solution providers.

The core strength of VinVal lies in material quality and precision in mechanical machining. VinVal products are designed to meet strict international standards such as JIS, DIN, ANSI. This ensures that every valve, when installed in the system, operates smoothly, minimizing leakage risks – a "vital" factor when operating toxic chemical systems.

VinVal's product range is very diverse, from butterfly valves, ball valves to stainless steel gate valves, serving many segments from domestic clean water to concentrated acid environments.

II. Common Chemicals Used in Industry and Their Impact

To choose the right valve used for chemicals, first, we need to clearly understand the "opponent" the valve must face. Not every valve can withstand every type of chemical. Below is the classification of common chemical groups and their impacts:

-

Acid Group

Strong inorganic acids such as Sulfuric Acid ($H_2SO_4$), Hydrochloric Acid ($HCl$), or Nitric Acid ($HNO_3$) are often used in metal pickling, fertilizer production, or water treatment.

-

Impact: Extremely fast metal corrosion. Cast iron or steel valves will often "evaporate" or rust severely after a short time of contact.

-

Solution: Must use Inox 304, 316, or high-grade plastics (UPVC, CPVC).

-

Alkali Group (Bases)

Typically Caustic Soda ($NaOH$), often used in paper, soap, and wastewater treatment industries.

-

Impact: Although less corrosive to metals than acids, they easily cause crystallization or damage common rubber sealing gaskets.

-

Solution: Pay attention to gasket material (should use Teflon/PTFE) alongside the stainless steel body.

-

Organic Solvents

Including gasoline, oil, alcohol, acetone...

-

Impact: Can cause swelling and deformation of rubber gaskets, leading to leakage.

III. VinVal Stainless Steel Gate Valve: The Optimal Solution for Chemicals

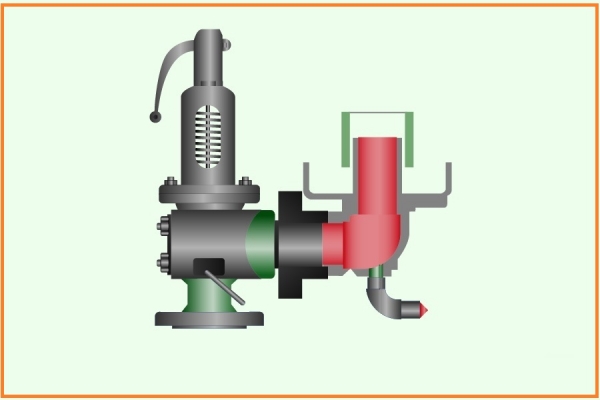

Among VinVal's product lines, the stainless steel gate valve is considered a "shining star" when applied in chemical environments.

Why choose VinVal Stainless Steel Gate Valve?

-

High-Grade Stainless Steel Material: VinVal uses solid cast Inox 304 (CF8) or Inox 316 (CF8M). Inox 316 contains Molybdenum which helps increase resistance to pitting and crevice corrosion in chloride (salt) and acid environments.

-

Optimized Flow Design: When fully open, the gate valve does not obstruct the flow, helping to maintain stable pressure and flow rate, avoiding chemical stagnation that causes sediment buildup at the valve.

-

PTFE Sealing Gasket: Unlike common rubber, VinVal equips PTFE (Teflon) gaskets capable of being inert to most chemicals and withstanding high temperatures.

If your system transports dilute acids, industrial wastewater, or corrosive solutions, VinVal's stainless steel gate valve is an economic and sustainable investment instead of constantly replacing cast iron valves.

IV. Notes When Installing and Operating Chemical Valves

Even if you own a good valve like VinVal, improper operation can still cause disaster.

-

Check Compatibility: Always cross-check chemical concentration and temperature with the valve's technical specifications.

-

Periodic Cleaning: For chemicals prone to crystallization, a regular pipeline flushing process is needed to prevent valve disc jamming.

-

Occupational Safety: When replacing or maintaining valves on chemical pipelines, it is mandatory to depressurize and wear full protective gear.

V. Frequently Asked Questions (FAQ)

-

Can VinVal stainless steel gate valves be used for hot concentrated acid?

For hot concentrated acids, even Inox 316 can be corroded. In this case, you should refer to VinVal's Lined Valve lines or more specialized materials like Inox 904L.

-

What is the difference between Inox 304 and 316 in industrial valves?

Inox 316 adds Molybdenum content (about 2-3%), helping it resist corrosion better than Inox 304, especially in marine environments (salt) and acidic chemicals. The cost of Inox 316 is also higher.

-

Can gate valves be used to regulate chemical flow?

No. Gate valves are designed for full Open/Close purposes (On/Off). If used for throttling (partially open), the valve disc will be quickly eroded by the chemical flow, causing valve failure. Globe Valves should be used for regulation.

-

Where to buy genuine VinVal valves?

You can directly contact authorized distributors or reputable industrial equipment agents to ensure buying genuine VinVal goods with a full warranty policy.

Related News

VinVal Industrial Water Valves: Stainless Steel Globe Valves & Pipeline Solutions from PM-E

20/12/2025

Discover high-quality VinVal industrial water valves. PM-E specializes in providing stainless steel globe valves and diverse fluid control solutions for your pipeline systems.

Steam Energy-Saving Solutions for Factories | Phuc Minh Engineering

17/12/2025

Optimize your steam system with Phuc Minh Engineering. Reduce energy loss, increase boiler efficiency, and cut fuel costs by 10–30%. Contact us now.

Flow Measurement & Pressure Control Solutions.

17/12/2025

Solutions for measuring flow and controlling pressure in steam, air, water, oil, and chemical systems. Optimize operations – reduce losses – enhance safety. Contact Phuc Minh.

What Is a Pressure Reducing Valve? Structure – Working Principle – How to Select the Best PRV for Industrial Plants (2025)

17/12/2025

A Pressure Reducing Valve (PRV) is a device used to reduce high inlet pressure to a stable, lower outlet pressure, helping protect piping systems, instruments, and machinery while improving operational safety. PRVs are widely used in: Steam systems Compressed air, gas, nitrogen Clean water – process water – chilled water Oil, chemicals, and other industrial media

Safety Valve For Steam Systems: Structure, Operation Principles & Selection Guide 2025 | Phuc Minh Engineering

17/12/2025

Learn what a steam safety valve is, how it works, different types, and how to select the correct valve for boilers and pipelines. EN/ASME-standard valves from Phuc Minh Engineering.

.png)