Operation Process of a Pump

Operation Process of a Pump

Pumps are vital components in numerous industrial systems, used for moving fluids such as water, chemicals, oil, and other liquids. Understanding how a pump operates is essential for ensuring efficient and reliable performance. Below is a detailed description of the operation process of a typical industrial pump, including its main components and steps involved in its operation.

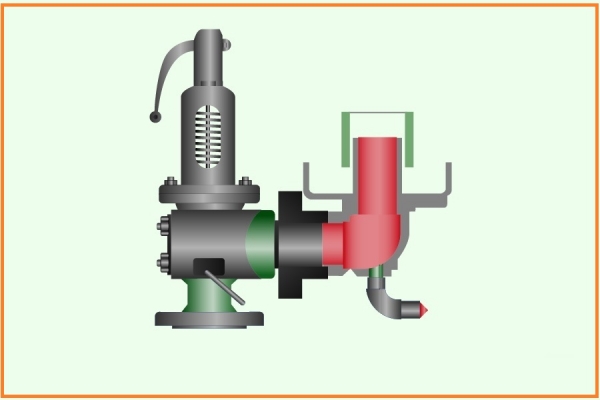

1. Basic Components of a Pump

Main Components:

- Pump Housing (Casing): The outer shell that contains all internal components and directs the flow of the fluid.

- Impeller: A rotating part that transfers energy to the fluid.

- Shaft: Connects the impeller to the motor and transmits the rotational energy.

- Motor: Provides the power to rotate the impeller.

- Suction Inlet: The point where the fluid enters the pump.

- Discharge Outlet: The point where the fluid exits the pump.

- Seals and Bearings: Prevent leaks and support the rotating shaft.

2. Operating Principle of a Pump

Operation Process:

-

Fluid Entry (Suction):

- Initial State: The pump is filled with the fluid to prime it, ensuring there is no air inside.

- Suction Inlet: Fluid enters the pump through the suction inlet, driven by atmospheric pressure or another driving force.

-

Impeller Rotation:

- Motor Activation: The motor powers the pump, causing the shaft and impeller to rotate.

- Centrifugal Force: In centrifugal pumps, the rotating impeller creates centrifugal force, pushing the fluid outward from the center of the impeller to the edges.

-

Energy Transfer:

- Kinetic Energy: As the impeller rotates, it imparts kinetic energy to the fluid, increasing its velocity.

- Pressure Increase: The high-velocity fluid is directed to the pump casing, where its kinetic energy is converted into pressure energy.

-

Fluid Movement (Discharge):

- Flow Direction: The casing directs the pressurized fluid towards the discharge outlet.

- Fluid Exit: The fluid exits the pump through the discharge outlet, moving towards its intended destination within the system.

-

Continuous Operation:

- Cycle Repetition: The process of fluid entry, energy transfer, and discharge continues as long as the pump is in operation.

- System Control: Flow rate and pressure can be regulated using control valves and speed adjustments of the motor.

3. Types of Pumps and Their Operation

Centrifugal Pump:

- Operation: Uses an impeller to create centrifugal force to move the fluid.

- Applications: Water supply, irrigation, chemical processing.

Positive Displacement Pump:

- Operation: Traps a fixed amount of fluid and forces it through the discharge pipe.

- Applications: Hydraulic systems, oil and gas transfer, food processing.

Diaphragm Pump:

- Operation: Uses a diaphragm to create a vacuum that draws fluid into the chamber, then pushes it out.

- Applications: Chemical handling, slurry pumping, pharmaceuticals.

Gear Pump:

- Operation: Uses meshing gears to pump fluid by displacement.

- Applications: Lubrication systems, chemical mixing, fuel transfer.

4. Advantages and Disadvantages of Pumps

Advantages:

- Versatility: Suitable for a wide range of fluids and applications.

- Efficiency: High efficiency in transferring energy to the fluid.

- Reliability: Durable and capable of operating under various conditions.

Disadvantages:

- Initial Cost: High initial investment for high-quality pumps.

- Maintenance: Requires regular maintenance to prevent wear and tear.

- Energy Consumption: Can consume significant energy, especially in large systems.

5. Applications of Pumps

Water Supply and Irrigation:

- Pumping water for domestic and agricultural use.

Chemical Processing:

- Handling and transferring chemicals in industrial processes.

Oil and Gas Industry:

- Transferring crude oil, natural gas, and refined products.

Food and Beverage Industry:

- Pumping liquids and semi-liquids in food production.

HVAC Systems:

- Circulating water and other fluids in heating, ventilation, and air conditioning systems.

Conclusion

Understanding the operation process of a pump is crucial for maintaining its efficiency and reliability in various industrial applications. By comprehensively grasping how pumps work, operators can ensure optimal performance, reduce downtime, and extend the lifespan of these essential components in industrial systems.

Related News

VinVal Industrial Water Valves: Stainless Steel Globe Valves & Pipeline Solutions from PM-E

20/12/2025

Discover high-quality VinVal industrial water valves. PM-E specializes in providing stainless steel globe valves and diverse fluid control solutions for your pipeline systems.

Steam Energy-Saving Solutions for Factories | Phuc Minh Engineering

17/12/2025

Optimize your steam system with Phuc Minh Engineering. Reduce energy loss, increase boiler efficiency, and cut fuel costs by 10–30%. Contact us now.

Flow Measurement & Pressure Control Solutions.

17/12/2025

Solutions for measuring flow and controlling pressure in steam, air, water, oil, and chemical systems. Optimize operations – reduce losses – enhance safety. Contact Phuc Minh.

What Is a Pressure Reducing Valve? Structure – Working Principle – How to Select the Best PRV for Industrial Plants (2025)

17/12/2025

A Pressure Reducing Valve (PRV) is a device used to reduce high inlet pressure to a stable, lower outlet pressure, helping protect piping systems, instruments, and machinery while improving operational safety. PRVs are widely used in: Steam systems Compressed air, gas, nitrogen Clean water – process water – chilled water Oil, chemicals, and other industrial media

Safety Valve For Steam Systems: Structure, Operation Principles & Selection Guide 2025 | Phuc Minh Engineering

17/12/2025

Learn what a steam safety valve is, how it works, different types, and how to select the correct valve for boilers and pipelines. EN/ASME-standard valves from Phuc Minh Engineering.

.png)