Engineering Plastics

What Are Engineering Plastics?

Engineering plastics are plastic materials that exhibit superior mechanical and thermal properties compared to commodity plastics. This material class can operate at temperatures of more than 150°C and hold tight tolerances and intricate geometrics, making it suitable for specialty industrial applications.

Our range of engineering plastics include:

-

PVC Sheets, Rods, Curtain Strips

-

PP, PE, PC, Sheets & Rods

-

Polyacetal, Nylon Rods

-

Nylon Rods & Sheets

-

POM Rods & Sheets

-

Acrylic Sheets

What are the Different Types of Engineering Plastics?

-

PVC Rigid Sheets & Rods: PVC Rigid Sheets & Rods offer high-impact strength, excellent thermal and electrical insulation, and easy fabrication. Industries utilise them in fabricating tanks and trunkings for corrosive environments, and their weathering properties make them suitable for use in process industries, construction, laboratories, and cladding.

-

PP (Polypropylene): PP materials have good chemical resistance and is ideal for various applications, including fabricating tanks, workbenches, and jigs used in chemically corrosive environments.

-

PE (Polyethylene): PE material exhibits non-toxic properties, chemical inertness, and excellent elongation. With impressive weldability, this material is ideal for fabricating chemical tanks, equipment, fittings, chopping blocks, and food equipment.

-

Polycarbonate (PC) Flat Sheets: PC flat sheets are known for their high-impact resistance, acoustical insulation, weather resistance, and lightweight properties. With its ease of installation and fabrication, these sheets are suitable for applications requiring transparency and safety as an alternative to glass.

-

Cast Polyamides (Nylon) PA6C & POM: Cast nylons are generally accepted as the primary engineering polymer, suitable for virtually any plain bearing application. Modifying the conditions of polymerisation allows for the customisation of mechanical properties to suit specific applications.

-

Polyoxymethylene - Polyacetals (POM): Polyacetals have excellent sliding and wear properties, striking a perfect balance of mechanical strength, toughness, and rigidity. With minimal moisture absorption, Polyacetals maintain consistent physical properties across changing environments. Ideal for close-tolerance mechanical parts, POM showcases excellent dimensional stability for reliable performance.

-

Acrylic Sheets: Acrylic sheets are transparent, lightweight, and durable plastic materials known for their strength, stiffness, and optical clarity. These characteristics make them durable substitutes for glass. These thermoplastic materials can be easily melted down, moulded into any shape, and reheated without degradation.

What are the Advantages of Engineering Plastics?

-

High Strength-to-Weight Ratio: Engineering plastics are stronger and more durable than other plastic materials while remaining relatively lightweight. This is crucial in situations where weight reduction is necessary without compromising structural integrity.

-

Chemical Resistance: The materials' resistance allows them to withstand exposure to various chemicals, acids, and solvents. This property makes engineering plastics suitable for industries with high exposure to harsh substances, such as electronics, aerospace, and automotive sectors.

-

Thermal Stability: With their exceptional thermal stability, engineered plastics can endure high or low temperatures without losing their mechanical properties or suffering serious degradation.

-

Design Flexibility: The molecular structure of engineering plastics facilitates easy customisation and moulding into complex shapes, enabling the creation of intricate and innovative designs that may be unattainable with other materials.

Why Choose Our Engineering Plastics

As a trusted provider of industrial-grade plastics, We ensures that our clients get:

Superior Quality

We offer high-quality products that can are suitable for different applications. Our products are sourced from trusted manufacturers to ensure every product we deliver to clients is durable and reliable.

Extensive Range

We are committed to providing a one-stop solution for clients across different industries. Our products encompass various materials, such as PVC, nylon, acrylic, and PTFE to ensure we can cater to our client’s specific requirements.

Expert Advice

In addition to our products, we actively provide industry-leading advice to our clients, assisting them in determining which products and materials best suit their needs. Our team is prepared to assist you from product inquiries and up to after-sales support.

Related News

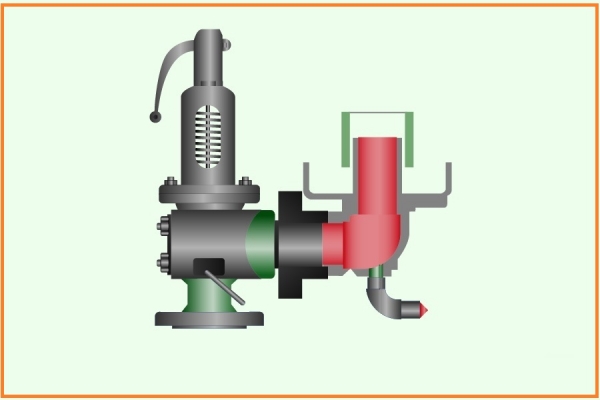

VinVal Industrial Water Valves: Stainless Steel Globe Valves & Pipeline Solutions from PM-E

20/12/2025

Discover high-quality VinVal industrial water valves. PM-E specializes in providing stainless steel globe valves and diverse fluid control solutions for your pipeline systems.

Steam Energy-Saving Solutions for Factories | Phuc Minh Engineering

17/12/2025

Optimize your steam system with Phuc Minh Engineering. Reduce energy loss, increase boiler efficiency, and cut fuel costs by 10–30%. Contact us now.

Flow Measurement & Pressure Control Solutions.

17/12/2025

Solutions for measuring flow and controlling pressure in steam, air, water, oil, and chemical systems. Optimize operations – reduce losses – enhance safety. Contact Phuc Minh.

What Is a Pressure Reducing Valve? Structure – Working Principle – How to Select the Best PRV for Industrial Plants (2025)

17/12/2025

A Pressure Reducing Valve (PRV) is a device used to reduce high inlet pressure to a stable, lower outlet pressure, helping protect piping systems, instruments, and machinery while improving operational safety. PRVs are widely used in: Steam systems Compressed air, gas, nitrogen Clean water – process water – chilled water Oil, chemicals, and other industrial media

Safety Valve For Steam Systems: Structure, Operation Principles & Selection Guide 2025 | Phuc Minh Engineering

17/12/2025

Learn what a steam safety valve is, how it works, different types, and how to select the correct valve for boilers and pipelines. EN/ASME-standard valves from Phuc Minh Engineering.

.png)