Boiler operating principles and safety protection

I. Operating principle of the boiler

1. What is a boiler system?

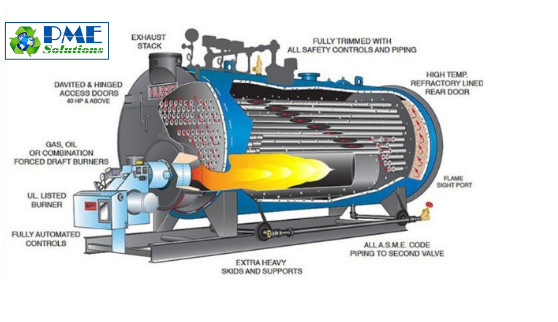

Industrial boiler systems, also known as steam boilers (Steam Boiler in English), use fuels such as coal, firewood, drums, oil, gas... to boil water to create high-temperature hot steam and great pressure. This amount of heat energy will be used to serve heat needs in many different areas.

2. Operating principle of industrial boiler?

When water is sucked or pumped circulated into storage tanks and boilers. At that time, the internal heater will burn the fuel to a maximum temperature of 20000C. Then, the heater stops burning and the water will begin to evaporate to form hot steam. The heat created will be sent through pipes to deliver heat to the devices that need it.

After a short time, when a lot of heat is released, the heat will gradually disappear and condense into water. The condensed water will continue to be returned to the boiler's water tank and this process will continue to circulate until the system is no longer needed.

3. The boiler's accompanying equipment

Water storage tank

Heat exchanger

Heating boilers

Air dryer

Dust filter cyclone

Cloth bag dust filter device

Electrostatic precipitator

Dust suppression tower

Dust suppression tank

Ash settling tank

In addition, industrial valves are indispensable equipment in boilers, specifically: safety valves, pressure reducing valves, one-way valves, gate valves, etc. The function of this device is to regulate pressure, ensuring The steam system operates safely and smoothly.

See more supplies for the steam industry ; Safe device

4. Why is it mandatory to have a safety valve in the boiler system?

The safety valve is the ultimate safety protection device. The boiler operates safely with no fire or explosion incidents occurring. If the pressure in the boiler exceeds the permissible limit for a long time, it can cause a fire or explosion, which can even cause serious damage to property and people.

The device is always equipped with a pull handle used to release water without having to wait for the set pressure. In this case, the steam safety valve will be like a regular relief valve. To help the entire system operate most effectively.

When installing the valve, it will be responsible for maintaining stable pressure in boiler equipment. This helps keep the entire system trouble-free and also improves work efficiency.

Phuc Minh we are currently the exclusive distributor of the following lines: Korean valves, Tozen valves, Taiwanese industrial valves.... If customers have needs, please contact the hotline for advice, support and accurate quotes.

PHUC MINH ENGINEERING COMPANY LIMITED

Hotline: +84902800728

Tel: +842835352125

Email: info@pm-e.vn

Website: www.pm-e.vn

Related News

inVal Industrial Valves: Stainless Steel Gate Valve Solution for Chemicals

20/12/2025

Discover VinVal industrial valve lines, especially specialized stainless steel gate valves. Learn how to select the most effective valve for corrosive chemicals

VinVal Industrial Water Valves: Stainless Steel Globe Valves & Pipeline Solutions from PM-E

20/12/2025

Discover high-quality VinVal industrial water valves. PM-E specializes in providing stainless steel globe valves and diverse fluid control solutions for your pipeline systems.

Steam Energy-Saving Solutions for Factories | Phuc Minh Engineering

17/12/2025

Optimize your steam system with Phuc Minh Engineering. Reduce energy loss, increase boiler efficiency, and cut fuel costs by 10–30%. Contact us now.

Flow Measurement & Pressure Control Solutions.

17/12/2025

Solutions for measuring flow and controlling pressure in steam, air, water, oil, and chemical systems. Optimize operations – reduce losses – enhance safety. Contact Phuc Minh.

What Is a Pressure Reducing Valve? Structure – Working Principle – How to Select the Best PRV for Industrial Plants (2025)

17/12/2025

A Pressure Reducing Valve (PRV) is a device used to reduce high inlet pressure to a stable, lower outlet pressure, helping protect piping systems, instruments, and machinery while improving operational safety. PRVs are widely used in: Steam systems Compressed air, gas, nitrogen Clean water – process water – chilled water Oil, chemicals, and other industrial media

.png)