Overview of Yamamoto Pressure Gauge Manufacturer from Japan

Yamamoto is a leading Japanese manufacturer specializing in pressure gauges and other pressure measurement devices. With decades of experience and a commitment to quality, Yamamoto has established a strong position in the international market.

History and Mission

Founded in the mid-20th century, Yamamoto has continuously grown over the years. With a mission to provide precise and durable pressure measurement devices, Yamamoto always prioritizes customer satisfaction and product quality. The company focuses on developing advanced technologies to meet the stringent demands of the market.

Main Products

Yamamoto offers a wide range of pressure measurement products, including:

- Mechanical Pressure Gauges: These products are designed with high durability and absolute accuracy, suitable for industrial and commercial applications.

- Digital Pressure Gauges: These devices offer modern features such as digital displays and the ability to connect with remote monitoring and control systems.

- Pressure Sensors: Yamamoto's pressure sensors are widely used in various industries for monitoring and controlling production processes.

- Measurement Accessories: In addition to its main products, Yamamoto also provides a range of accessories like valves, connectors, and protective devices to ensure measurement systems operate efficiently and safely.

Quality and Innovation

Yamamoto is renowned for its commitment to product quality. Each product undergoes rigorous testing before reaching customers. The company also invests heavily in research and development to stay at the forefront of new technology applications, ensuring its products meet the highest industry standards.

Market and Customers

Yamamoto serves a wide range of customers, from heavy industries like oil and gas and chemicals to lighter industries such as food and beverages. Yamamoto's products are trusted in many countries due to their reliability and high performance.

Commitment and Future

Yamamoto is committed to continuous improvement to meet the growing demands of the global market. The company always listens to feedback from customers and partners to refine its products and services. In the future, Yamamoto plans to expand its market reach and continue developing advanced pressure measurement products, contributing to the efficiency and safety of various industries.

Conclusion

With decades of experience in the pressure measurement field, Yamamoto has established itself as a leading manufacturer in Japan and globally. The combination of product quality, advanced technology, and strong customer commitment has made Yamamoto a trusted name in the industry.

Related News

VinVal Industrial Water Valves: Stainless Steel Globe Valves & Pipeline Solutions from PM-E

20/12/2025

Discover high-quality VinVal industrial water valves. PM-E specializes in providing stainless steel globe valves and diverse fluid control solutions for your pipeline systems.

Steam Energy-Saving Solutions for Factories | Phuc Minh Engineering

17/12/2025

Optimize your steam system with Phuc Minh Engineering. Reduce energy loss, increase boiler efficiency, and cut fuel costs by 10–30%. Contact us now.

Flow Measurement & Pressure Control Solutions.

17/12/2025

Solutions for measuring flow and controlling pressure in steam, air, water, oil, and chemical systems. Optimize operations – reduce losses – enhance safety. Contact Phuc Minh.

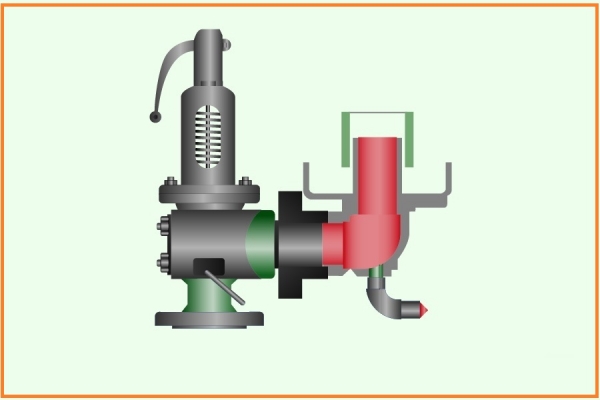

What Is a Pressure Reducing Valve? Structure – Working Principle – How to Select the Best PRV for Industrial Plants (2025)

17/12/2025

A Pressure Reducing Valve (PRV) is a device used to reduce high inlet pressure to a stable, lower outlet pressure, helping protect piping systems, instruments, and machinery while improving operational safety. PRVs are widely used in: Steam systems Compressed air, gas, nitrogen Clean water – process water – chilled water Oil, chemicals, and other industrial media

Safety Valve For Steam Systems: Structure, Operation Principles & Selection Guide 2025 | Phuc Minh Engineering

17/12/2025

Learn what a steam safety valve is, how it works, different types, and how to select the correct valve for boilers and pipelines. EN/ASME-standard valves from Phuc Minh Engineering.

.png)