Other Devices

Check Valves

CK Series

Check valves for steam and other fluids

Disc and spring construction assures stable performance with installation in either vertical or horizontal pipelines. TLV CK series check valves are ideal for nearly all types of fluid processes with their high sealing performance in both vertical and horizontal piping and their rapid open-close mechanism.

CK Series Check Valves Pamphlet (198 KB)

Benefits and Features

- Small valve-opening pressure differential.

- Select between a metal valve seat or a soft valve seat for use with steam, water or air.

- Available in sizes up to 4 inch on some models.

- All stainless steel construction (CK3M/CK3T/CK3R also available in brass or bronze).

-

Reliably Prevents Backflow

-

Check valves utilize a mechanical sealing mechanism to prevent backflow.

-

By providing a tight seal, backflow is safely avoided.

-

-

Easy to Use

-

Compact design.

-

There are no restrictions on installation orientation (horizontal, vertical).

-

After the valve has closed, it opens again at the slightest pressure differential.

-

-

Long Service Life

-

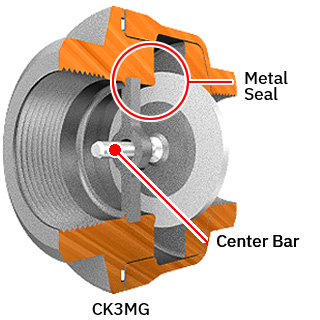

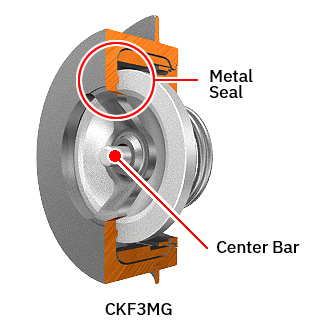

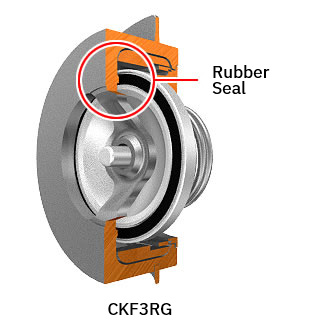

TLV’s unique center-guided disc (CK3MG, CKF3MG, CKF3RG) offers greater durability.

-

Application Areas

- Piping that requires backflow prevention.

- Locations where frequent opening and closing operation is expected.

Screwed Connection

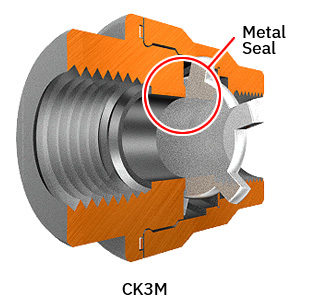

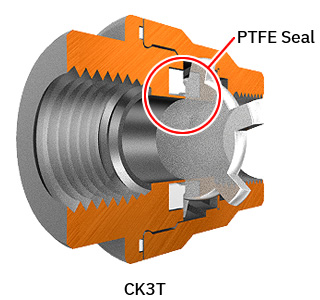

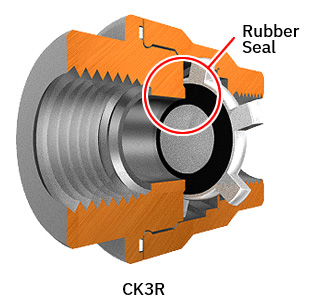

CK3M/CK3T/CK3R: Select among 3 types of sealing surfaces, depending on the temperature and fluid requirements

| Applicable Fluids | Max. Operating Temperature TMO (°C) | Sealing Surface | Model | Photo | Catalogue |

|---|---|---|---|---|---|

| Steam | 220℃ | Metal | CK3M |

|

|

| Steam, Hot water | 185℃ | PTFE | CK3T | ||

| Air, water, water | 90℃ | Nitrile Rubber (NBR) | CK3R |

|

|

|

CK3MG: Center-guided disc and large flow area ensure superior durability and capacity

| Applicable Fluids | Max. Operating Temperature TMO (°C) | Sealing Surface | Model | Photo | Specifications |

|---|---|---|---|---|---|

| Steam, hot water, water | 220℃ | Metal | CK3MG |

|

Specifications |

|

Wafer-construction (flangeless)

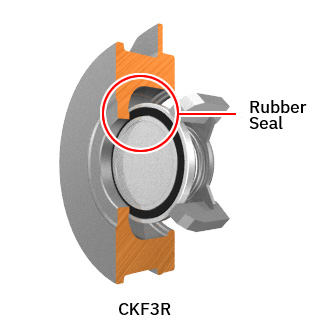

CKF3M/CKF3R: Compact stainless steel check valves

| Applicable Fluids | Max. Operating Temperature TMO (°C) | Sealing Surface | Model | Photo | Specifications |

|---|---|---|---|---|---|

| Steam, hot water, water | 350℃ | Metal | CKF3M |

|

Specifications |

| Air, water, water | 150℃ | Fluorine Rubber (FPM) | CKF3R |

|

|

CKF3MG/CKF3RG: Center-guided disc and large flow area ensure superior durability and capacity

| Applicable Fluids | Max. Operating Temperature TMO (°C) | Sealing Surface | Model | Photo | Specifications |

|---|---|---|---|---|---|

| Steam, hot water, water | 350℃ | Metal | CKF3MG |

|

Specifications |

| Air, water, water | 150℃ | Fluorine Rubber (FPM) | CKF3RG |

.jpg)

|

|

Product Details

| Model | Photo | Connection | Body Material | Applicable Fluids | PMO (MPaG) | Min. Opening Differential Pressure (MPa)* | TMO (°C) | Sealing Surface Material | Catalogue | Manual |

|---|---|---|---|---|---|---|---|---|---|---|

| CK3M |

|

Screwed | Brass (C3604) |

Steam | 1.0 | 0.002 | 220 | Metal | Specifications | Manual |

| Bronze (CAC407) |

||||||||||

| Stainless Steel (ASTM A351 Gr.CF8) |

2.1 | |||||||||

| CK3T | Screwed | Brass (C3604) |

Steam Hot water |

1.0 | 0.002 | 185 | PTFE | |||

| Bronze (CAC407) |

||||||||||

| Stainless Steel (ASTM A351 Gr.CF8) |

1.6 | |||||||||

| CK3R | Screwed | Brass (C3604) |

Air Hot water Water |

1.0 | 0.002 | 90 | NBR | |||

| Bronze (CAC407) |

||||||||||

| Stainless Steel (ASTM A351 Gr.CF8) |

1.6 | |||||||||

| CK3MG |

|

Screwed | Stainless Steel (ASTM A351 Gr.CF8) |

Steam Hot water Water |

2.1 | 0.001 | 220 | Metal | Specifications | Manual |

| CKF3M |

|

Wafer | Stainless Steel (ASTM A351 Gr.CF8) |

Steam Hot water Water |

3.0 | 0.002 | 350 | Metal | Specifications | Manual |

| CKF3R | Wafer | Stainless Steel (ASTM A351 Gr.CF8) |

Air Hot water Water |

1.6 | 0.002 | 150 | FPM | |||

| CKF3MG |

|

Wafer | Stainless Steel (ASTM A351 Gr.CF8) |

Steam Hot water Water |

3.0 | 0.001 | 350 | Metal | Specifications | Manual |

| CKF3RG | Wafer | Stainless Steel (ASTM A351 Gr.CF8) |

Air Hot water Water |

1.6 | 0.001 | 150 | FPM |

- PMO = Maximum Operating Pressure

- TMO = Maximum Operating Temperature

- The latest version of each product's instruction manual can be found on this page.

*When the valve has remained closed for a long period of time, the valve and the valve seat may stick, increasing the necessary minimum opening differential pressure.

Related projects

.png)