Plastic & Rubber Gasket

Price: Contact

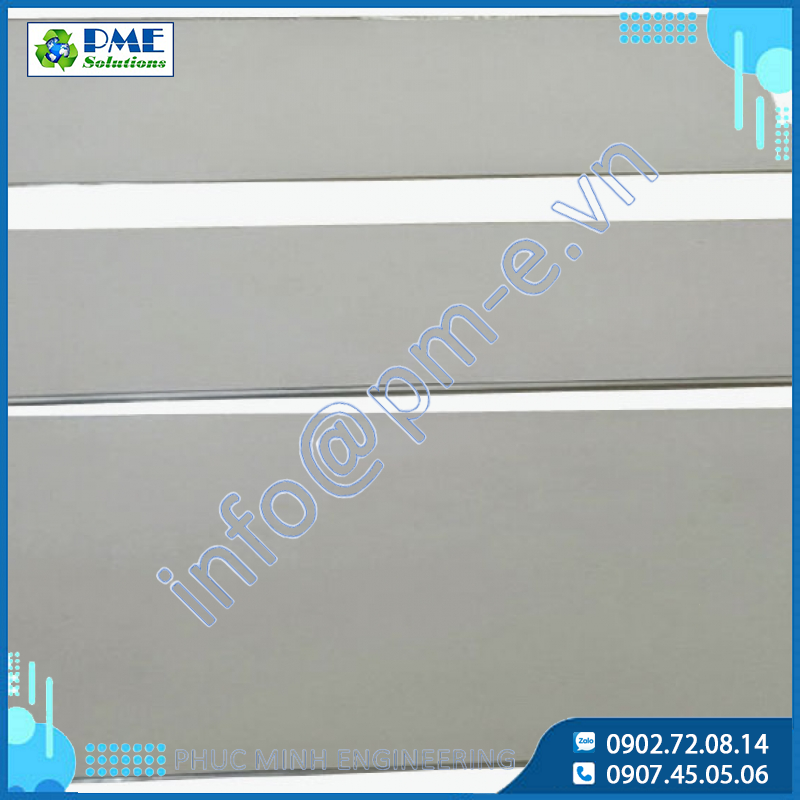

Wj 4600 PTFE Sliding Plate - WOOJU GASPACK

Wj 4600

PTFE Sliding Plate

Characteristic

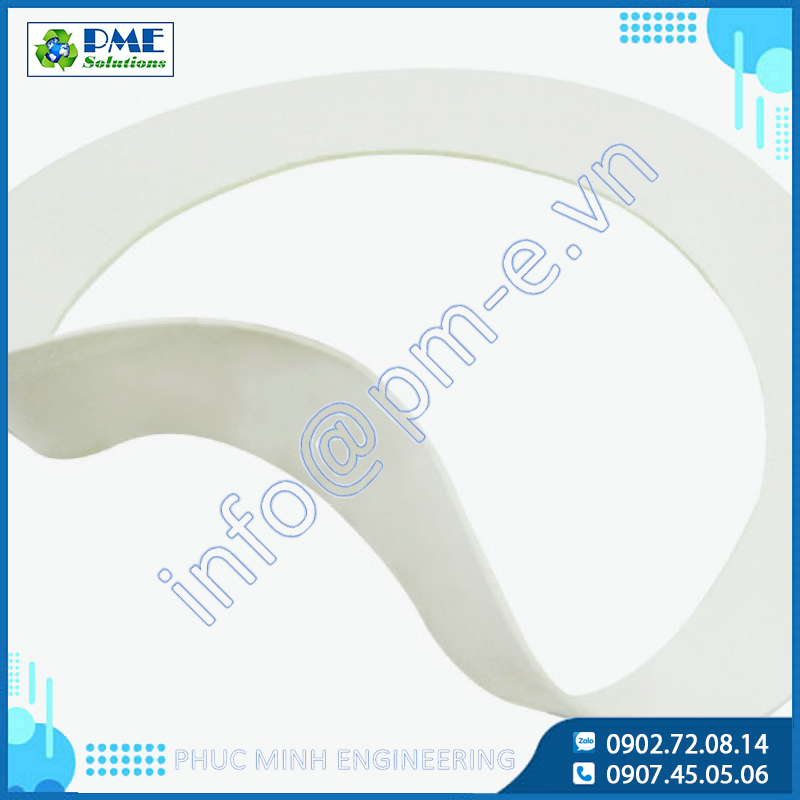

PTFE Sliding Plate is used to enhance the durability of facilities by absorbing various environmental changes, vibration and impacts. It is used as a cushioning materials for steel structures, piping bridges, ship drying equipment, and equipment other than fresh water plants.

Outline

Sliding Plate is bearing plate float to slide smooth such as may be part of the expansion joints of bridges, pipe, and other mechanical or structural engineering application when equipment is floating by temperature, vibration, earthquake, and other impact.

Application

A large size pipe, boiler, a heat exchanger, a bridge of highway, a bridge of railroad, pipe in vessel, etc.

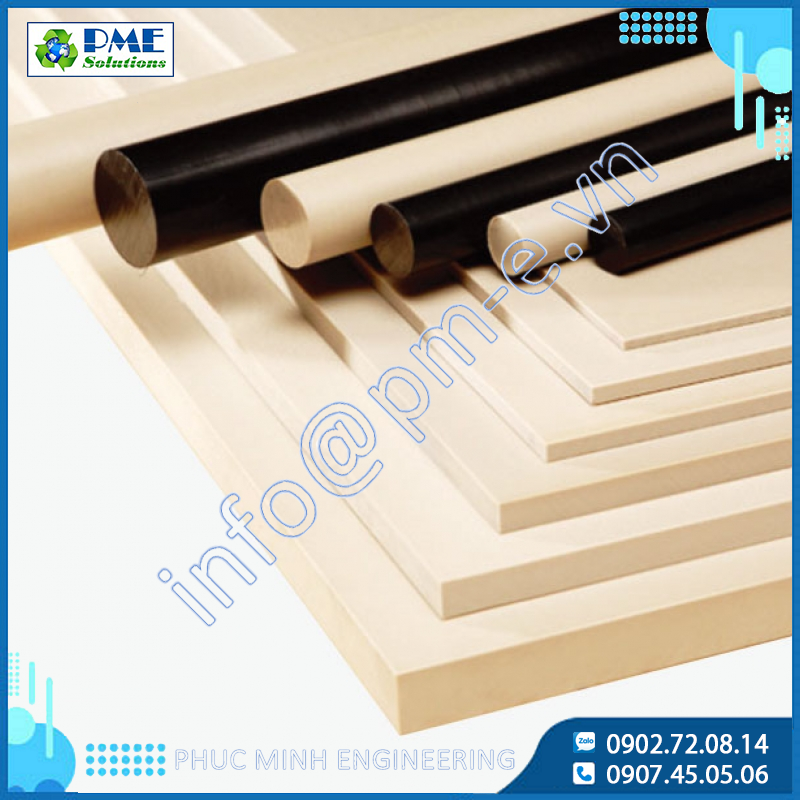

Type of sliding plate

Stainless Steel, Carbon Steel, Copper Alloy, etc.

Physical Properties

| Description | Unit | Test Method | Virgin PTFE | PTFE + CARBON 25% | PTFE + GLASS 25% |

|---|---|---|---|---|---|

| Mechanical Properties | MPa | JIS K 6891 | 46.1 | 16.7 | 18.6 |

| Tensile Strength | |||||

| Elongation | % | JIS K 6891 | 370 | 30 | 280 |

| Compressive Strength | MPa | 0.2% off set | 7.6 | 11.3 | 8.6 |

| 24℃ | |||||

| 1% strain | 5.4 | 10 | 8.3 | ||

| 24℃ | |||||

| 25% strain | 28 | 39.8 | 28.9 | ||

| 24℃ | |||||

| Total Deformation | % | ASTM D621 | 15.2 | 6.4 | 14 |

| 14.5 | 5.5 | 8.5 | |||

| Hardness | Tage D | Shore, 24℃ | 52 ~ 62 | 65 ~ 75 | 56 ~ 60 |

| Durometer | |||||

| Coefficient of Friction | Static | 0.22 | 0.29 | 0.26 | |

| Dynamic | 0.048 | 0.09 | 0.085 | ||

| Wear Factor | 2.0 x 10-4 | 2.0 x 10-4 | 1.0 x 10-4 | ||

| Physical Properties | 2.17 | 1.93 | 2.25 | ||

| Specific Gravity |

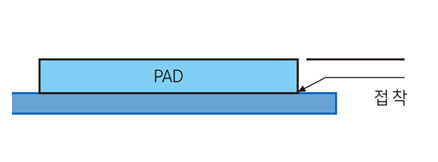

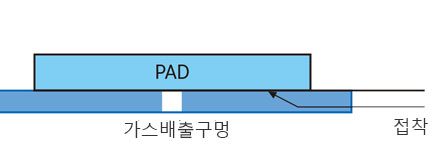

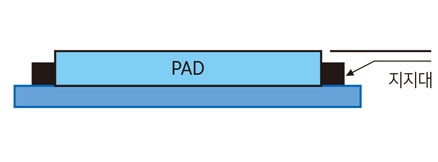

| kết cấu | lời giải thích |

|---|---|

|

Adhered to the metal plate by bonding(etching) onside of the PTFE plate is suitable for places where load is generally low and construction is simple |

|

It is suitable for application under heavy loads. There are no risk that PAD detached from others by loads because PAD is fixed in groove. |

|

PAD is fixed in frame weld and attach supporter to PAD. It is easy to construct and economical than above one, and expected above way s effectiveness. |

Life and wear coefficient

- For a typical sliding pad, pressure and sliding speed are important variables, but wear is also a variable.

- wear variable

- Basic variables: load, speed, time

- nature of motion (e.g. reciprocating, oscillating, rotating)

- Environmental conditions such as the presence of oil or water on the sliding pad surface

- Material of counterpart material, surface roughness

- R = K · P · V · T(Archard wear equation)

- R = wear in the radial direction cm

- K = wear coefficient cm3 . min/kg. m. h

- P = The load per unit area of the object in contact with the pad kg/cm2

- V = sliding speed m/min

Related projects

.png)