Plastic & Rubber Gasket

Price: Contact

Plastic & Rubber Gaskets - PTFE Product - WOOJU GASPACK

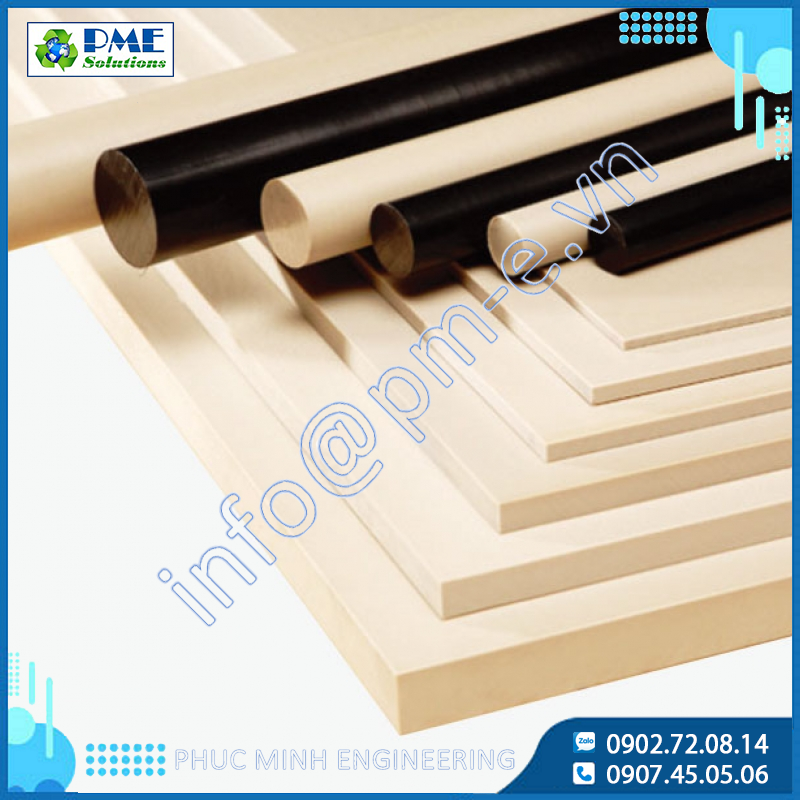

Plastic & Rubber Gaskets

PTFE Product

Characteristic

PTFE is a high polymer including fluorine atom. PTFE provides excellent chemical resistance, low friction, and wear resistance. Especially, this product is suitable to use in acid and alkali material because it has chemical and thermal resistance. lt manufactured as sheet, bar, and pipe, and possible to work various shapes. lt is available to combine with glass, graphite, carbon, bronze to prevent transformation by pressure, load, RPM (Revolutions per minute).

| Property | Method | Units | Specification |

|---|---|---|---|

| Specific Gravity | ASTM D 792 | 2,180 ~ 2,230 | |

| Tensile Strength | ASTM D 792 | Mpa | 20 |

| Elongation | ASTM D 792 | % | 250 ~ 350 |

| Hardness | ASTM D 792 | Shore D | 55 ~ 60 |

| Deformation Underload (14N/mm2, 24h at 23℃) |

ASTM D 792 | % | 11 ~ 13 |

| Volume Resistivity | ASTM D 792 | Ωcm | 10 |

| Service Temperature | ℃ | -20/+260 |

.jpg)

| Section Style |

|---|

| Wj4000(Pure PTFE Sheet) |

| Wj4005(Pure PTFE Rod) |

| Wj4008(PTFE Pipe) |

| Wj4010(PTFE Gasket) |

| Wj4010S(PTFE Serration Gasket) |

| Wj4020(PTFE Special Product) |

Wj 4010 - R-PTFE

(Reinforced Polytetrafluoroethylene)

RTFE (Reinforced PTFE) is compounded with different filler materials (Glass, Carbon, Graphite, Bronze, etc.) and PTFE to enhance mechanical properties

Wj 4010-G Glass filled PTFE

Characteristic

Glass is th most commonly used filler in PTFE. Glass is used as a PTFE filler as it offers much improved compression and wear properties.

Strengths and Weakness

| Strengths | - Wear resistance - Improved hardness - Lower thermal expansion and deformation under load - Non-conductive |

|---|---|

| Weakness | - Higher coefficient of friction - Abrasive filler unsuitable for some applications - Resistance to gas permeation is reduced |

Wj 4010-CA Carbon filled PTFE

Characteristic

Carbon filled PTFE benefits from improved compressive strength, reduced deformation under heavy loads, and better wear resistance than pure PTFE. Because carbon is conductive, it is suitable for applications which require higher thermal conductivity than PTFE alone and also becomes static dissipative due to its electrical conductivity.

Strengths and Weakness

| Strengths | - Good thermal and electrical conductivity - Good chemical resistance - Improved wear resistance under load and permanent deformation - Good performance in damp conditions |

|---|---|

| Weakness | - High percentage fillers mean low elongation - Conductivity can be a problem |

Wj 4010-GR Graphite filled PTFE

Characteristic

Graphite filled PTFE provides some similar benefits to 'normal' carbon filled PTFE but without the greatly improved wear resistance. Graphite lowers the coefficient of friction and friction and Graphite filled PTFE has excellent self- lubricating properties.

Strengths and Weakness

| Strengths | - Good chemical compatibility - Good thermal conductivity - Low coefficient of friction and low permeability - Excellent wear resistance properties, especially to soft metals - Improved wear resistance under load and permanent deformation |

|---|---|

| Weakness | - Lower compressive strength - Not be used in extremely dry and vacuum applications |

Wj 4010-BR Bronze filled PTFE

Characteristic

f your application demands good thermal and electrical conductivity, bronze filled PTFE may be ideal. Adding bronze to PTFE also improves wear resistance. However, bronze attenuates the non-stick properties and chemical inertness of the PTFE, so you should consider whether these are important for particular situation.

Strengths and Weakness

| Strengths | - Extremely hard-wearing materia - Very heavy - high specific gravity - Good thermal and electrically conductivity - The best wear properties of any filled PTFE - Great deformation strengths |

|---|---|

| Weakness | - Not suitable for electrical applications - Not ideal to work with chemicals |

Related projects

.png)