Technical corner

What is a pressure reducing valve? Structure, Operating Principle, Adjustment and Classification of Pressure Reducing Valves.

02/10/2024

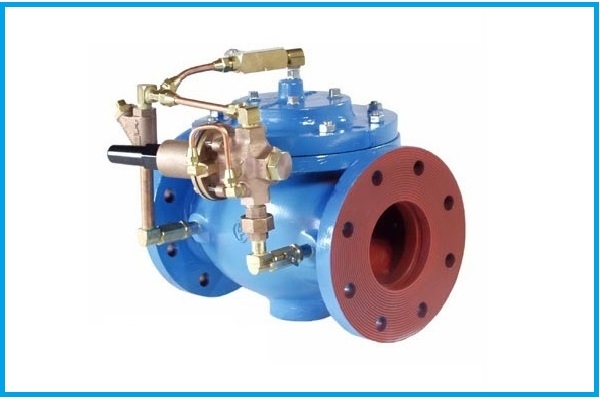

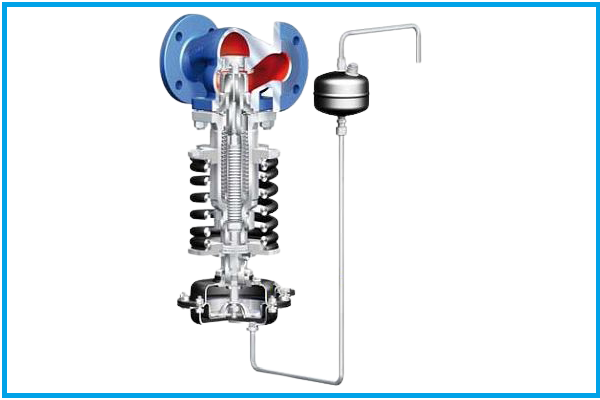

Pressure Reducing Valve is also known as pressure regulator, pressure stabilizer, pressure regulating valve, etc. It is a type of industrial valve installed on the pipeline, with the function of reducing pressure and stabilizing output pressure, so that the output pressure is always smaller than the input pressure of the system, helping fluids to be easily transmitted to different devices. but the pressure is not too different.

Benefits, Functions, and Applications of "Pressure Reducing Valves" / "Pressure Regulating Valves

02/10/2024

Pressure reducing valves, also known as pressure regulating valves, are critical devices in industrial piping systems that help control and maintain safe pressure levels, protecting equipment from damage due to overpressure. Below is a detailed analysis of the benefits, functions, and applications of pressure reducing valves.

Benefits and uses of safety valves

02/10/2024

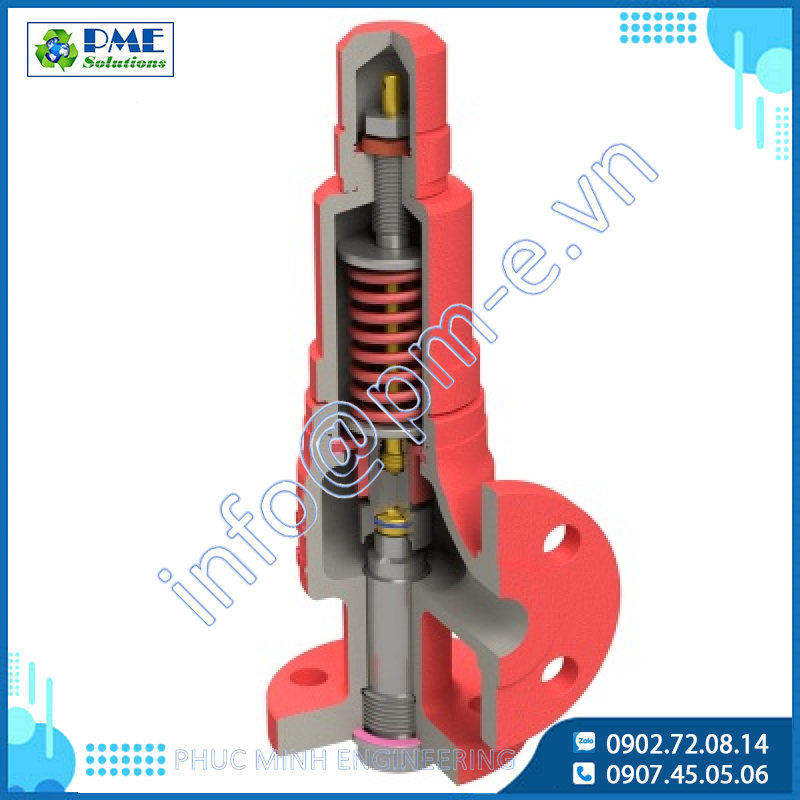

Safety valves are essential devices in industrial systems, designed to protect equipment and ensure operator safety. Below is a detailed analysis of the benefits and applications of safety valves.

.png)