10 Most Important Industrial Equipment in Factories

10 Most Important Industrial Equipment in Factories

Modern industrial factories rely on a range of equipment to maintain high performance and ensure continuous operation. Below is a detailed description of the 10 most important types of industrial equipment, including their functions, applications, advantages, and disadvantages.

Industrial Pumps

Description: Industrial pumps are used to move liquids, including water, chemicals, oil, and various other fluids in industrial systems.

Function:

Pumping and distributing liquids.

Maintaining pressure in the system.

Assisting in fluid and chemical processing operations.

Advantages:

High efficiency and good durability.

Diverse types suitable for various applications.

Easy to maintain and repair.

Disadvantages:

High initial investment cost.

Requires regular maintenance to maintain performance.

High energy consumption.

Applications:

Oil and gas industry.

Water and wastewater treatment.

Food and beverage industry.

Chemical industry.

Air Compressors

Description: Air compressors are mechanical devices used to increase the pressure of air by reducing its volume.

Function:

Providing compressed air for industrial tools and equipment.

Maintaining air pressure in systems.

Supporting production and processing operations.

Advantages:

High compression efficiency.

Long lifespan and durability.

Various power and size options.

Disadvantages:

High energy consumption.

Requires regular maintenance.

Can produce noise and vibrations.

Applications:

Manufacturing industry.

Construction industry.

Food and beverage industry.

Oil and gas and chemical industries.

Boilers

Description: Boilers are devices that use thermal energy to produce steam or hot water for industrial processes.

Function:

Producing steam for industrial processes.

Providing heat for heating systems.

Supporting production processes that require a large amount of heat.

Advantages:

High efficiency and quick steam production.

Diverse designs suitable for various applications.

High durability and easy maintenance.

Disadvantages:

High investment and operating costs.

Requires regular maintenance and inspection.

Safety risks if not operated properly.

Applications:

Food and beverage industry.

Textile industry.

Paper and pulp industry.

Chemical and oil and gas industries.

Heat Exchangers

Description: Heat exchangers are devices used to transfer heat between two or more fluids without them coming into direct contact.

Function:

Transferring heat between fluids.

Increasing energy efficiency in systems.

Used in cooling and heating processes.

Advantages:

High heat transfer efficiency.

Flexible and diverse designs.

Easy to maintain and clean.

Disadvantages:

Can become clogged if the fluids contain particulates.

High initial investment cost.

Requires regular inspection and maintenance.

Applications:

Oil and gas and chemical industries.

Food and beverage industry.

Energy industry.

HVAC (heating, ventilation, and air conditioning) systems.

Wastewater Treatment Systems

Description: Wastewater treatment systems are a collection of equipment and technologies used to clean industrial wastewater before discharging it into the environment or reusing it.

Function:

Treating and removing contaminants from wastewater.

Ensuring wastewater meets environmental safety standards.

Reusing water after treatment.

Advantages:

Protecting the environment and water resources.

Increasing water usage efficiency in industry.

Reducing wastewater treatment costs.

Disadvantages:

High investment and operating costs.

Requires advanced technical and technological expertise.

Needs continuous maintenance and operation.

Applications:

Food and beverage industry.

Chemical and pharmaceutical industries.

Textile and dyeing industry.

Paper and pulp industry.

Automated Control Systems

Description: Automated control systems are a collection of electronic devices and software used to monitor and control industrial production processes automatically.

Function:

Monitoring and controlling production processes.

Automating processes to increase efficiency.

Collecting and analyzing production data.

Advantages:

Increasing the accuracy and efficiency of production processes.

Reducing human errors.

Optimizing costs and productivity.

Disadvantages:

High initial investment cost.

Requires skilled personnel to operate and maintain.

Dependence on electricity and IT systems.

Applications:

Manufacturing industry.

Food and beverage industry.

Chemical and pharmaceutical industries.

Electronics and automation industry.

CNC Machining Tools

Description: CNC (Computer Numerical Control) machining tools are automated mechanical devices that use computer programs to control machining processes.

Function:

Precisely machining components.

Creating complex and diverse products.

Increasing productivity and reducing machining time.

Advantages:

High precision and uniformity.

Ability to machine complex components.

Minimizing human errors.

Disadvantages:

High initial investment cost.

Requires skilled technicians to operate and program.

Requires regular maintenance and inspection.

Applications:

Manufacturing industry.

Automotive and aerospace industries.

Electronics and telecommunications industries.

Medical and dental industries.

Conveyor Systems

Description: Conveyor systems are mechanical devices used to transport goods and materials within industrial factories.

Function:

Transporting materials and products from one point to another.

Increasing transportation efficiency and reducing production time.

Reducing labor costs and increasing safety.

Advantages:

Increasing productivity and transportation efficiency.

Reducing labor costs and production time.

Easy to integrate into existing production processes.

Disadvantages:

High initial investment cost.

Requires ample installation space.

Needs regular maintenance.

Applications:

Food and beverage industry.

Warehousing and logistics industry.

Electronics manufacturing industry.

Construction and materials industry.

Non-Destructive Testing Equipment

Description: Non-destructive testing (NDT) equipment is used to inspect and evaluate the quality of materials and products without damaging them.

Function:

Detecting defects in materials and products.

Evaluating the quality and durability of products.

Ensuring the safety and performance of equipment and structures.

Advantages:

Inspecting and evaluating without causing damage.

Detecting the smallest defects in materials.

Increasing product reliability and safety.

Disadvantages:

High investment and operating costs.

Requires skilled technicians to perform inspections.

Dependence on testing technology and equipment.

Applications:

Oil and gas and chemical industries.

Aerospace industry.

Metal and materials manufacturing industry.

Construction and mechanical industries.

Industrial Air Filtration Systems

Description: Industrial air filtration systems are devices used to remove dust, smoke, and pollutants from the air in factories and production facilities.

Function:

Filtering and removing dust and pollutants from the air.

Improving air quality and protecting worker health.

Ensuring compliance with environmental standards.

Advantages:

Improving the working environment and protecting worker health.

Increasing production efficiency by minimizing the impact of dust and pollution.

Easy to install and maintain.

Disadvantages:

High investment and operating costs.

Requires regular maintenance and filter replacement.

Filtration efficiency may decrease over time.

Applications:

Manufacturing industry.

Food and beverage industry.

Electronics manufacturing industry.

Pharmaceutical and chemical industries.

Conclusion

The industrial equipment mentioned above plays a crucial role in ensuring the efficient and continuous operation of factories. Selecting and using the right type of equipment suitable for technical requirements and working environments is essential to achieve high performance and ensure safety in production processes. We hope this article has provided valuable information to help you better understand important industrial equipment and their applications in practice.

Contact Info:

Phuc Minh Engineering Company Limited

Email: info@pm-e.vn

Tel: 028-3535.2125

Fax: 028-3535.0254

Web: pm-e.vn

Address: 92/38 Street 12, Quarter 18, Binh Hung Hoa Ward, Binh Tan District, Ho Chi Minh City.

Zalo: 0902720814 - 0907450506 - 0902800728 - 0979737351

Related News

FDA-Approved Rubber Gaskets – Safe Solutions for Food & Medical Applications

23/04/2025

FDA-Approved Rubber Gaskets – Safe Solutions for Food & Medical Applications Phuc Minh Engineering Co., Ltd. is proud to be one of the leading distributors in Vietnam of rubber gaskets for food and medical applications. Our products are made from high-quality materials and meet the strict FDA (U.S. Food and Drug Administration) standards – ensuring safety for direct contact with food and medical equipment.

HIGH-TEMPERATURE GASKETS – UP TO 1000°C WITH THERMa-PUR™ 4122 MATERIAL

23/04/2025

HIGH-TEMPERATURE GASKETS – UP TO 1000°C WITH THERMa-PUR™ 4122 MATERIAL In many heavy industries such as chemical processing, oil refining, cement, and power generation, sealing materials must endure extreme temperatures, high pressure, and harsh oxidative environments. Phuc Minh Engineering Co., Ltd. is proud to be a distributor of high-temperature gaskets rated up to 1000°C, combining Garlock’s advanced THERMa-PUR™ 4122 material with Corrugated Metal Gaskets (CMG) – delivering an optimal sealing solution for extreme industrial conditions.

Trusted Industrial Valve Distributor – Industry Leader

26/02/2025

With the continuous growth of Vietnam's economy, the demand for industrial valves and related technical solutions has significantly increased. In this article, we would like to introduce a reputable and leading industrial valve distributor in this field — Phuc Minh Engineering Co., Ltd.

Top 10 best water flow meter brands today

12/02/2025

Sensus water flow meter: Origin: Germany. Advantages: The product has high precision, durable design and stable operation in many different environmental conditions. Sensus clocks are certified by European CO, CQ, suitable for large-scale projects.

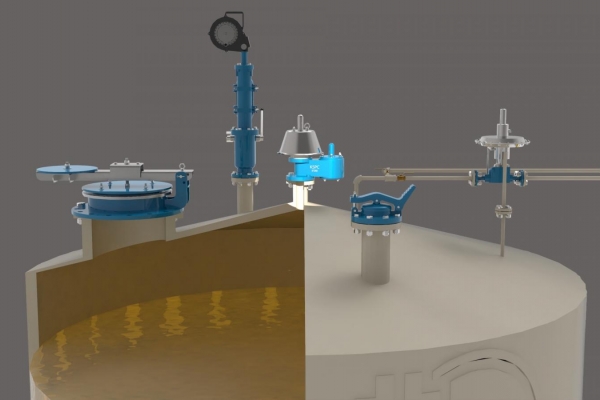

What Is a Breather Valve?

05/02/2025

A breather valve, also known as a pressure-vacuum relief valve (PVRV), is a safety device that protects storage tanks from explosion or collapse caused by pressure differences. It is typically installed on top of storage tanks for fuels, chemicals, LPG, or gases.

.png)