DK VALVE Korea Cast Steel Valves

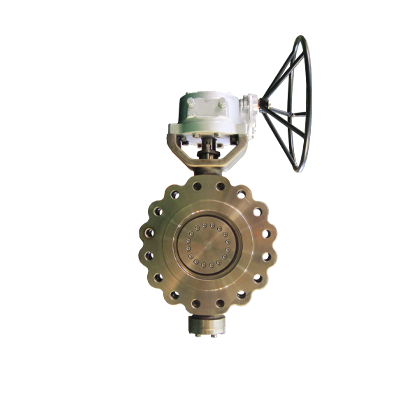

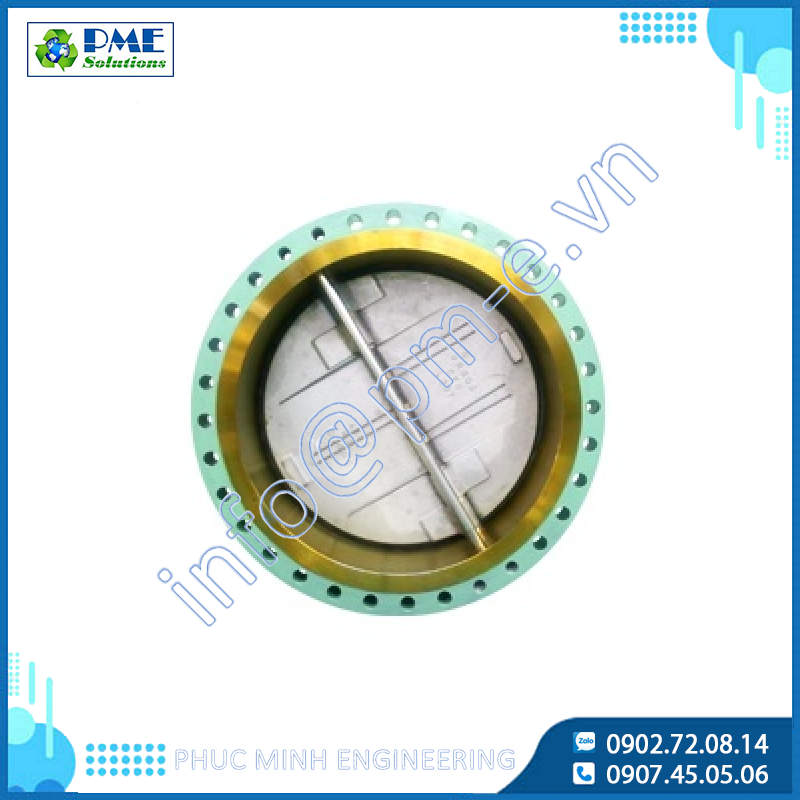

Triple offset butterfly valve

Triple Offset Geometry

▪ 1st offset :

The valve stem is offset behind the seat axis to allow complete sealing contact around the entire seat.

▪ 2nd offset :

The shaft centerline is offset from the pipe and valve which provides interference free opening and closing of the valve.

▪ 3rd offset :

The seat cone axis is offset from the shaft centerline to eliminate friction during closing and opening and to achieve uniform compressive sealing around the entire seat.

With this geometry, seat seal interference is completely eliminated ensuring long sealing life. The result is torque seating, process pressure aided frictionless seal.

The geometry allows the body seat to be used as the closed limit stop, aiding operator adjustment. The triple offset design is ideally suited to metal seated valves providing

bubble-tight performance on high temperature, high pressure and fire safe application.

Standard Specifications

DESIGN

▪ API 609 Cat.B

▪ ASME B 16.34

FACE-TO-FACE

▪ API 609 Cat. B

▪ Wafer and Lugged

▪ Double flange Short/Long

FLANGE STANDARD

▪ ASME B 16.5/16.47

▪ BS 4504 / EN 1092-1

▪ JIS B2220

▪ Others on request

PRESSURE RATING

▪ ASME B 16.34

▪ Class 150/300/600

▪ Class 900/1500

NOMINAL DIAMETER

NOMINAL DIAMETER

▪ 3” to 144”

▪ DN 80 to 3600

OTHER OPTIONS

▪ Anti-static device

▪ Cryogenic design

▪ Others on request

TESTING

▪ API 598

▪ ASME B 16.104 / FCI 70-2

▪ ISO 5208

Applicable Materials

| Carbon Steel | A105, A216 WCB / WCC / WC6 / WC9 |

| Low Temp. Carbon Steel | A350 LF2, A352 LCB / LCC |

| Austenitic Stainless Steel | A182 F304 / F316, A351 CF8 / CF8M / CF3 / CF3M |

| Duplex Stainless Steel | A182 F51 / F53 / F55, A995 4A / 5A / 6A |

| Special Alloy | Inconel® 625(UNS N06625), 254SMO®(UNS S31254) Monel® K400 / 500 (UNS N04400 / N05500) |

Related projects

.png)