DK VALVE Korea Cast Steel Valves

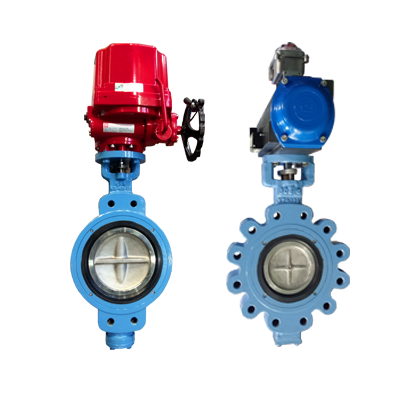

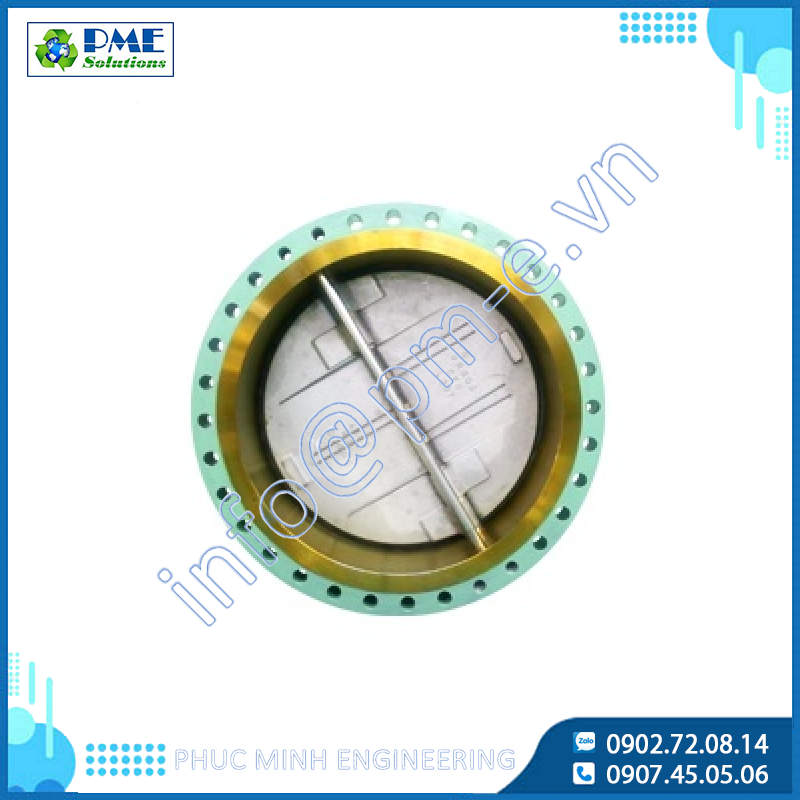

Double eccentric butterfly valve

Double Eccentric Geometry

▪ 1st offset :

The first offset is achieved by locating the shaft downstream of the centerline of the seat. This allows for a totally unobstructed 360 degree sealing surface.

▪ 2nd offset :

The second offset locates the shafts off-center of the vertical axis of the seat.

The combination of these two offsets creates a cam effect as the disc swings into and out of the seat. The disc lifts quickly out of the seat in the first few degrees of travel

and does not contact the seat again until it is nearly closed. There are no wear points between the seat and disc, while operating torques are reduced and seat life is extended.

Standard Specifications

DESIGN

▪ API 609 Cat.B

▪ ASME B 16.34

FACE-TO-FACE

▪ API 609 Cat. B

▪ Wafer and Lugged

▪ Double flange Short/Long

FLANGE STANDARD

▪ ASME B 16.5/16.47

▪ BS 4504 / EN 1092-1

▪ JIS B2220

▪ Others on request

PRESSURE RATING

▪ ASME B 16.34

▪ Class 150/300

NOMINAL DIAMETER

▪ 2” to 144”

▪ DN 50 to 3600

OTHER OPTIONS

▪ Fire safe design

▪ Anti-static device

▪ Cryogenic design

▪ Others on request

TESTING

▪ API 598

▪ ASME B 16.104 / FCI 70-2

▪ ISO 5208

Applicable Materials

| Carbon Steel | A105, A216 WCB / WCC / WC6 / WC9 |

| Low Temp. Carbon Steel | A350 LF2, A352 LCB / LCC |

| Austenitic Stainless Steel | A182 F304 / F316, A351 CF8 / CF8M / CF3 / CF3M |

| Duplex Stainless Steel | A182 F51 / F53 / F55, A995 4A / 5A / 6A |

| Special Alloy | Inconel® 625(UNS N06625), 254SMO®(UNS S31254) Monel® K400 / 500 (UNS N04400 / N05500) |

Related projects

.png)