Operating Principle of a Boiler

I./Operating Principle of a Boiler and Safety Measures

Operating Principle of a Boiler

A boiler, also known as a steam generator, is a device that converts water into steam using heat generated from fuel combustion. This steam is then used for various industrial purposes such as heating, power generation, and running machinery. Below is a basic overview of how a boiler operates:

-

Fuel and Combustion System:

-

Fuel: Fuel, which can be coal, oil, gas, or biomass, is fed into the boiler's combustion chamber.

-

Combustion: The fuel is burned in the combustion chamber, generating heat. This process requires a supply of air or oxygen to sustain combustion.

-

-

Heat Transfer:

-

Direct Heat Transfer: The heat generated from combustion is directly transferred to water through the heat exchange surfaces of water tubes or steam pipes.

-

Convection and Radiation Heat Transfer: Heat is also transferred via radiation from the flame and convection from the combustion gases.

-

-

Water to Steam Conversion:

-

Water Reservoir: Water is stored in a reservoir and comes into contact with the heat exchange surfaces.

-

Boiling and Evaporation: As heat is transferred to the water, its temperature rises until it reaches the boiling point and begins to evaporate, producing high-pressure steam.

-

-

Steam Collection and Utilization:

-

Steam Collection: The generated steam is collected and directed through steam pipes to various systems for utilization.

-

Steam Use: The steam is used to generate mechanical power, heat, or electricity.

-

II/ Safety Measures for Boilers

Ensuring safety in boiler operation is crucial. Here are several safety measures to protect boiler operations:

-

Pressure Control Systems:

-

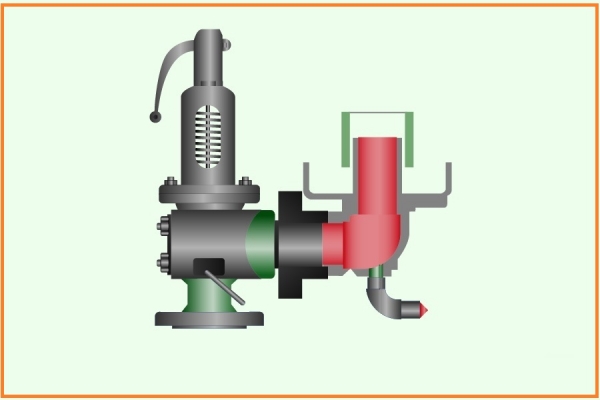

Safety Valves: Safety valves are installed to release excess pressure if it exceeds safe levels.

-

Pressure Gauges: These help monitor and ensure pressure remains within safe limits.

-

-

Temperature Control Systems:

-

Temperature Sensors: These monitor the water and steam temperature to ensure it does not exceed safe levels.

-

Thermostats: Automatically adjust the temperature to maintain safe operating conditions.

-

-

Water Level Control:

-

Water Level Alarms: Warn when the water level is too low or too high, preventing damage from water shortage or overflow.

-

Feed Water Controllers: Ensure a continuous and stable supply of water to the boiler.

-

-

Emergency Protection Systems:

-

Emergency Shut-off Systems: Allow immediate shutdown of the boiler in case of emergency.

-

Safety Switches: Automatically cut off power if any faults or hazards are detected.

-

-

Regular Maintenance and Inspection:

-

Routine Maintenance: Regularly inspect and maintain the boiler to ensure all components function properly.

-

Comprehensive Inspections: Perform detailed inspections, including pressure testing, water quality testing, and safety device checks.

-

-

Training and Education of Personnel:

-

Safety Training: Ensure operators are thoroughly trained in safety procedures and boiler operation.

-

Ongoing Training: Provide regular updates and training sessions to keep personnel informed about the latest safety practices and technologies.

-

By implementing these measures, boiler operation becomes safer, reducing the risk of accidents and ensuring efficient production while protecting the health and safety of workers.

Related News

VinVal Industrial Water Valves: Stainless Steel Globe Valves & Pipeline Solutions from PM-E

20/12/2025

Discover high-quality VinVal industrial water valves. PM-E specializes in providing stainless steel globe valves and diverse fluid control solutions for your pipeline systems.

Steam Energy-Saving Solutions for Factories | Phuc Minh Engineering

17/12/2025

Optimize your steam system with Phuc Minh Engineering. Reduce energy loss, increase boiler efficiency, and cut fuel costs by 10–30%. Contact us now.

Flow Measurement & Pressure Control Solutions.

17/12/2025

Solutions for measuring flow and controlling pressure in steam, air, water, oil, and chemical systems. Optimize operations – reduce losses – enhance safety. Contact Phuc Minh.

What Is a Pressure Reducing Valve? Structure – Working Principle – How to Select the Best PRV for Industrial Plants (2025)

17/12/2025

A Pressure Reducing Valve (PRV) is a device used to reduce high inlet pressure to a stable, lower outlet pressure, helping protect piping systems, instruments, and machinery while improving operational safety. PRVs are widely used in: Steam systems Compressed air, gas, nitrogen Clean water – process water – chilled water Oil, chemicals, and other industrial media

Safety Valve For Steam Systems: Structure, Operation Principles & Selection Guide 2025 | Phuc Minh Engineering

17/12/2025

Learn what a steam safety valve is, how it works, different types, and how to select the correct valve for boilers and pipelines. EN/ASME-standard valves from Phuc Minh Engineering.

.png)