Comprehensive Valve and Process Control Solutions for Key Industries

Comprehensive Valve and Process Control Solutions for Key Industries

1. Water Treatment Industry – Scale and Challenges

Water treatment is a vital sector, ensuring safe water supply for both residential and industrial use. As urbanization and industrialization accelerate, water treatment systems must meet increasingly stringent requirements:

-

Ensure output water quality meets national and international standards.

-

Maintain continuous, stable operation while minimizing unexpected downtime.

-

Optimize energy efficiency and reduce operational and maintenance costs.

-

Integrate monitoring and automation for enhanced remote control and management.

-

Comply with strict environmental protection regulations and carbon emission reduction goals.

Recommended Solutions: Specialized industrial valves, sensors, and process control devices supplied by Phuc Minh Engineering, tailored to meet the complex demands of modern water treatment plants.

2. Textile Dyeing Industry – Valve and Process Control Solutions

The textile dyeing industry is a key manufacturing sector facing specific challenges:

-

High energy consumption in heating, washing, dyeing, and drying processes.

-

Precise temperature and pressure control to ensure fabric quality.

-

Reliable system operation in harsh industrial environments.

-

Standard-compliant wastewater treatment to protect the environment.

Phuc Minh Valve Solutions: High-temperature, high-pressure resistant valves, precision control equipment, and automated systems designed to improve energy efficiency and system stability.

3. Instant Noodle Manufacturing Industry – Optimal Control Solutions

The instant noodle production industry requires continuous operation with strict food safety and process control standards:

-

Precise control of temperature and pressure in steaming, frying, and seasoning processes.

-

Optimization of steam and frying oil usage to reduce operating costs.

-

Ensuring system stability and accuracy in heat exchange and steam distribution.

-

Guaranteeing operational safety and minimizing pressure and temperature-related incidents.

Phuc Minh Offers:

-

Steam valves, pressure valves, and high-quality flow and pressure measurement devices.

-

Automated control solutions for continuous, stable production lines.

4. Chemical Industry – Specialized Solutions for Harsh Environments

The chemical industry operates in highly corrosive and hazardous conditions, requiring:

-

Accurate flow and level control of chemicals in tanks and pipelines.

-

Safe operation with minimal risk of chemical leaks.

-

High corrosion resistance to ensure equipment durability.

-

Advanced automation for monitoring and controlling processes safely and efficiently.

Phuc Minh’s Solutions: Corrosion-resistant specialty valves, liquid level sensors, and fully automated chemical flow and level control systems.

5. Fire Protection Systems (Fire Fighting) – High-Quality Valves

Phuc Minh Engineering supplies a wide range of UL/FM-certified fire protection valves, including:

-

Gate valves, butterfly valves, globe valves, angle valves, check valves, ball valves, and sprinkler heads.

-

High durability and reliability for commercial buildings, residential projects, industrial plants, and oil & gas facilities.

-

Compliance with international standards for fire protection systems.

6. HVAC Systems (Heating, Ventilation, Air Conditioning) – Complete Solutions

Phuc Minh provides high-quality HVAC products and solutions designed to optimize temperature, humidity, and air quality while saving energy:

-

Mechanical Valves: Butterfly valves, ball valves, gate valves, check valves made from stainless steel and ductile iron for durability and high performance.

-

Control Valves: Pneumatic and electric actuators for precise flow and pressure regulation.

-

Flow Meters: For accurate water and gas flow monitoring.

-

Pressure and Temperature Gauges: For system monitoring, adjustment, and safety.

Sourced from leading international brands: VYC (Spain), Nacional (Spain), Ritag (Germany), KSPC (Korea), Yamamoto (Japan), Conval (USA), OCV (USA), Boscarol (Italy), Kunkle (USA), Gasso (Spain), etc.

Phuc Minh Engineering is committed to providing optimal, energy-efficient HVAC solutions for all projects.

Related News

VinVal Industrial Water Valves: Stainless Steel Globe Valves & Pipeline Solutions from PM-E

20/12/2025

Discover high-quality VinVal industrial water valves. PM-E specializes in providing stainless steel globe valves and diverse fluid control solutions for your pipeline systems.

Steam Energy-Saving Solutions for Factories | Phuc Minh Engineering

17/12/2025

Optimize your steam system with Phuc Minh Engineering. Reduce energy loss, increase boiler efficiency, and cut fuel costs by 10–30%. Contact us now.

Flow Measurement & Pressure Control Solutions.

17/12/2025

Solutions for measuring flow and controlling pressure in steam, air, water, oil, and chemical systems. Optimize operations – reduce losses – enhance safety. Contact Phuc Minh.

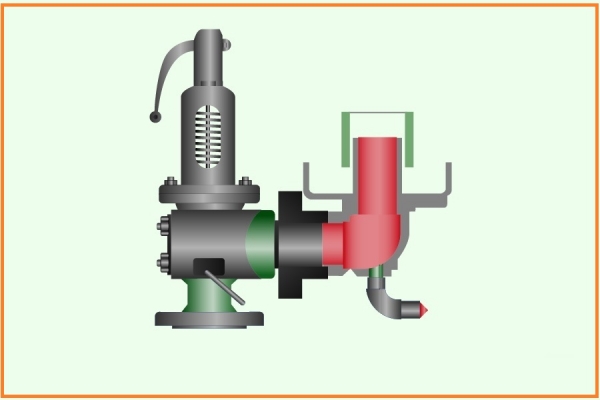

What Is a Pressure Reducing Valve? Structure – Working Principle – How to Select the Best PRV for Industrial Plants (2025)

17/12/2025

A Pressure Reducing Valve (PRV) is a device used to reduce high inlet pressure to a stable, lower outlet pressure, helping protect piping systems, instruments, and machinery while improving operational safety. PRVs are widely used in: Steam systems Compressed air, gas, nitrogen Clean water – process water – chilled water Oil, chemicals, and other industrial media

Safety Valve For Steam Systems: Structure, Operation Principles & Selection Guide 2025 | Phuc Minh Engineering

17/12/2025

Learn what a steam safety valve is, how it works, different types, and how to select the correct valve for boilers and pipelines. EN/ASME-standard valves from Phuc Minh Engineering.

.png)