DKM-KOREA

Introduction:

In the realm of industrial equipment and fluid control systems, South Korea has emerged as a hub of innovation and excellence. Among the many companies contributing to this reputation is DKM Valve, a prominent player in the valve manufacturing industry. Renowned for its commitment to quality, technological advancement, and customer satisfaction, DKM Valve stands as a testament to South Korea's prowess in engineering and manufacturing.

DKM Valve in Korea:

DKM Valve, headquartered in Korea, is a leading manufacturer of industrial valves, catering to diverse sectors such as oil and gas, petrochemicals, power generation, and water treatment. With a focus on precision engineering and innovative design, DKM Valve has earned a reputation for delivering reliable, high-performance valve solutions tailored to meet the unique needs of its customers.

Specializing in a wide range of valve types, including gate valves, globe valves, ball valves, check valves, DKM Valve offers comprehensive solutions for fluid control applications across various industries. Whether it's ensuring the safety and efficiency of oil refineries, optimizing water distribution networks, or maintaining precise control in chemical processing plants, DKM Valve's products are trusted by engineers and operators worldwide.

Backed by state-of-the-art manufacturing facilities and a team of experienced engineers and technicians, DKM Valve maintains stringent quality control standards throughout the production process. From the selection of materials to the final testing phase, every aspect of valve manufacturing is meticulously monitored to ensure compliance with international standards and customer specifications.

Furthermore, DKM Valve is committed to continuous innovation and technological advancement. By investing in research and development, and embracing emerging trends such as digitalization and automation, DKM Valve aims to stay ahead of the curve and provide cutting-edge solutions that address the evolving needs of its customers in an ever-changing industry landscape.

In summary, DKM Valve exemplifies excellence in valve manufacturing, blending Korean ingenuity with global best practices to deliver reliable, high-quality products that drive efficiency, safety, and performance across industries. As a trusted partner to its customers, DKM Valve continues to set the standard for innovation and excellence in the fluid control industry.

DongKang (DKM) Valve Distributor in Vietnam

Overview

DongKang (DKM) is a leading manufacturer of forged steel valves in Korea, specializing in producing high-temperature and high-pressure forged steel valves.

DKM is equipped with a superior quality control system that meets ISO 9001:2008 standards and has been granted patents by the Korean Intellectual Property Office for its valve lines used in hydropower plants, petrochemical refineries, thermal power plants, and more, thanks to the advanced anti-leak technology of DKM valves.

DongKang (DKM) Valve Agent in Vietnam

DKM is a premium Korean valve line made from forged steel, widely used in the market. To ensure you purchase genuine DKM products and avoid counterfeit, fake, or low-quality goods, please contact the official DKM agents in Vietnam.

Phúc Minh Engineering Company is proud to be the official DKM valve distributor in Vietnam. All DKM valves we distribute come with import documents and customs declarations that can be provided to customers upon request. The genuine DKM products distributed by Phúc Minh offer the most competitive prices in the market. With a team of experienced technicians, we always provide enthusiastic and dedicated consultation when you reach out to us. Phúc Minh is a leading distributor of industrial valves and equipment in Vietnam, promising to bring you genuine products and brands at the best prices on the market.

Please contact our hotline at 028 - 3535.2125 or 0907.45.05.06 - 0902.72.08.14 or send your inquiry to info@pm-e.vn for consultation and quotation.

The DongKang (DKM) valve products currently distributed by Phúc Minh include the following:

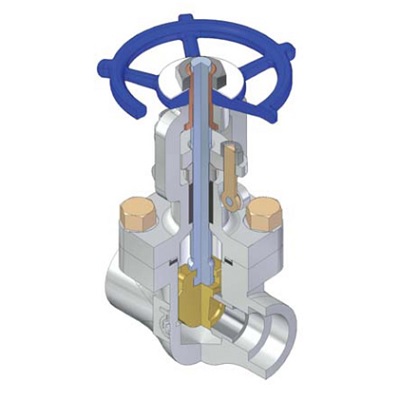

1. GATE VALVE

- DESCRIPTION

- Serves as efficient stop valves with flow in either direction. They are commonly used where a minimum of pressure drop is important because they offer practically no resistance to flow when fully open. Throttling is not conducive to accurate and consistent flow control. Also the valves may be damaged by the high velocity across the seats. They function best fully open or fully closed.

- CLASS

- API 800, 1500

ANSI 150, 300, 600, 900, 1500, 2500 - SIZE

- 3/8", 1/2" , 3/4" , 1" , 1 1/4" , 1 1/2" , 2"

- MATERIAL

- ASTM A105, A182-F5, A182-F9, A182-F11, A182-F22, A182-F304, A182-F316,

A182-F304L, A182-F316L, A182-F321, A182-F347, A182-F51, A182-F91, A350-LF2

Other Materials also Available on Application - END CONNECTION

- SOCKET WELDING, THREADED, BUTT WELDING, FLANGED

- FEATURE

- BOLTED BONNET OR WELDED BONNET OUTSIDE SCREW & YOKE SOLID WEDGE DISC RENEWABLE SEAT

2. GLOBE VALVE

- DESCRIPTION

- Are ideal for throttling service. Their flow characteristics permit accurate and repeatable flow control. However, caution must be exercised to avoid extremely close throttling when pressure drop exceeds 20%. This creates excessive noise, vibration, and possibly damage to valves and piping. When these conditions are anticipated, consult dong-kang for recommendations.

- CLASS

- API 800, 1500

ANSI 150, 300, 600, 900, 2500, 4500 - SIZE

- 3/8" , 1/2" , 3/4" , 1" , 1 1/4" , 1 1/2" , 2"

- MATERIAL

- ASTM A105, A182-F5, A182-F9, A182-F11, A182-F22, A182-F304, A182-F316,

A182-F304L, A182-F316L, A182-F321, A182-F347, A182-F51, A182-F91, A350-LF2

Other Materials also Available on Application - END CONNECTION

- SOCKET WELDING, THREADED BUTT WELDING, FLANGED

- FEATURE

- BOLTED BONNET OR WELDED BONNET OUTSIDE SCREW & YOKE

PLUG DISC INTEGRAL SEAT

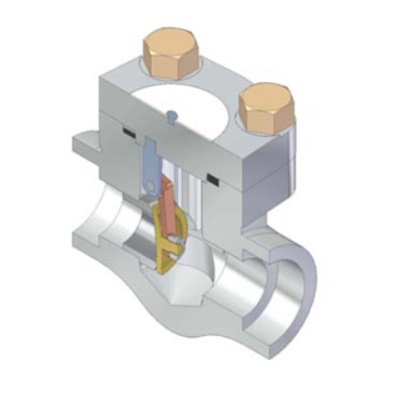

3. DONGKANG SWING CHECK VALVE

DESCRIPTION

Prevent reversal of flow through pipe lines. The swing check valve uses a hinged door to open during flow and to close against a pressure reversal. Most Dong-kang swing check valves can be installed in horizontal or vertical upward flow piping. they offer low resistance to flow and are particularly suited to low velocity service.

CLASS

- API 800, 1500

- ANSI 150, 300, 600, 900, 2500, 4500

SIZE

- 3/8" , 1/2" , 3/4" , 1" , 1 1/4" , 1 1/2" , 2"

MATERIAL

- ASTM A105, A182-F5, A182-F9, A182-F11, A182-F22, A182-F304, A182-F316,

- A182-F304L, A182-F316L, A182-F321, A182-F347, A182-F51, A182-F91, A350-LF2

- Other Materials also Available on Application

END CONNECTION

- SOCKET WELDING, THREADED BUTT WELDING, FLANGED

FEATURE

- BOLTED COVER OR WELDED COVER RENEWABLE SEAT

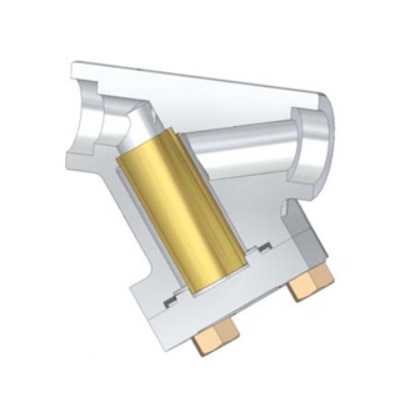

4. Y-STRAINER

- DESCRIPTION

- Y Strainers for Forged take their name from their configuration. They are most commonly used in pressurized lines, gas or liquid, but can also be used in suction or vacuum conditions. They are intended for applications where small amounts of solid particulate are expected, and where clean-out will be infrequent. If solids will flush easily from the screen, and fluid can be exhausted to atmosphere, a blow-down valve on the drain port will allow clean-out without removal of the screen, and without interrupting the process flow.

- CLASS

- API 800, 1500

ANSI 150, 300, 600, 900, 1500, 2500 - SIZE

- 3/8", 1/2" , 3/4" , 1" , 1 1/4" , 1 1/2" , 2"

- MATERIAL

- ASTM A105, A182-F304, A182-F304L, A182-F316, A182-F316L, ETC

- END CONNECTION

- SOCKET WELDING, THREADED, BUTT WELDING, FLANGED

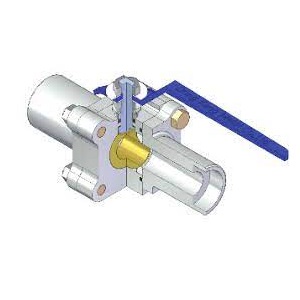

5. BALL VALVE

- DESCRIPTION

- The DKM Ball Valves reflect many years of manufacturing and field testing based on accepted design criteria and sound engineering practices. You can rely on these ball valves to provide dependable, low cost, safe operation with which the name DKM has been associated for nearly 20 years throughout the process piping industry.

- CLASS

- API 800, 1500

ANSI 150, 300, 600, 900, 1500, 2500 - SIZE

- 3/8", 1/2" , 3/4" , 1" , 1 1/4" , 1 1/2" , 2"

- MATERIAL

- ASTM A105, A182-F304, A182-F304L, A182-F316, A182-F316L, ETC

- END CONNECTION

- SOCKET WELDING, THREADED, BUTT WELDING, FLANGED

For details please contact:

Phuc Minh Engineering Co., Ltd

🏢 92/38 No 12 Street, Quarter 18, Binh Hung Hoa Ward, Binh Tan Disctrict, Ho Chi Minh City.

☎️ (028) 3535.2125 – 0902720814 - 0907450506

📥 sales@pm-e.vn/ info@pm-e.vn

🌐 www.pm-e.vn

.png)