VINVAL Float Steam Trap – The Optimal Solution for Industrial Steam Systems

VINVAL Float Steam Trap – The Optimal Solution for Industrial Steam Systems

Welcome to Phuc Minh Industrial Valves – the official importer and distributor of VINVAL Float Steam Traps in Vietnam. We are proud to present the VINVAL product line, a premium solution for effectively removing condensate, minimizing steam loss, and maximizing efficiency in industrial steam systems.

Why Choose the VINVAL Float Steam Trap?

1. Efficient Condensate Removal

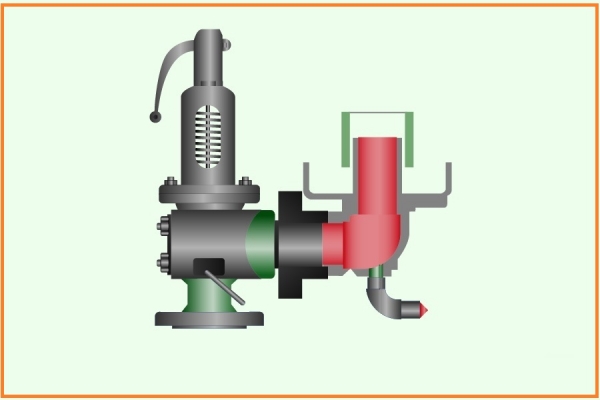

The VINVAL float steam trap operates automatically based on the density difference between condensate and steam. When condensate accumulates, the float rises and opens the discharge valve. As condensate levels drop, the float lowers and closes the valve. This ensures:

-

Optimal heat transfer

-

Prevention of water hammer

-

System safety and reliability

2. Maximum Energy Savings

Thanks to its airtight construction and integrated air vent, the VINVAL steam trap offers:

-

Reduced steam losses

-

Increased boiler efficiency

-

Lower fuel and maintenance costs

It is the ideal choice for businesses seeking energy-saving and sustainable solutions.

3. Long Service Life

Manufactured with high-quality stainless steel or cast iron, VINVAL traps withstand high pressure and temperatures. Corrosion-resistant and wear-resistant design ensures durability and long-term reliability, minimizing replacement costs.

4. Easy Installation & Maintenance

With a compact and modular design, VINVAL steam traps are easy to install and service. Phuc Minh Industrial Valves provides detailed technical guides and on-site installation and maintenance services, helping your team operate efficiently and safely.

Widely Used Across Various Industries

VINVAL steam traps are used in steam systems for:

-

✅ Food & Beverage (sterilization, drying)

-

✅ Chemical Industry (process heating, drying)

-

✅ Textile Industry (dyeing machines, finishing machines)

-

✅ Pulp & Paper (paper drying, water treatment)

-

✅ HVAC systems (buildings, malls, hospitals)

-

✅ Oil & Gas and Power Plants

Popular VINVAL Steam Trap Models

Phuc Minh Industrial Valves offers a wide range of VINVAL steam traps:

-

Basic Float Steam Trap – Simple, efficient, and cost-effective

-

Float Trap with Automatic Air Vent – Enhances heat transfer and removes non-condensable gases

-

High-Pressure Float Steam Trap – Ideal for power and chemical plants

-

Float Trap with Built-in Check Valve – Easy inspection and quick maintenance

How to Select the Right VINVAL Steam Trap

When selecting a VINVAL steam trap, consider the following factors:

-

✅ System pressure and temperature

-

✅ Condensate load

-

✅ Specific application (drying, heating, deaeration, etc.)

-

✅ Material compatibility (cast iron, stainless steel)

-

✅ Pipe connection size and type

Our experienced engineers are always available to help you select the most efficient solution.

Full-Service Maintenance & Technical Support

Phuc Minh Industrial Valves offers comprehensive services for all VINVAL steam traps:

-

🔧 Routine inspection and troubleshooting

-

♻️ Cleaning and genuine spare part replacement

-

📐 System optimization and upgrade consultation

We are committed to delivering efficient – reliable – sustainable solutions for your operations.

Why Choose Phuc Minh Industrial Valves?

-

✅ Official distributor of VINVAL in Vietnam

-

✅ Over 10 years of experience in industrial equipment supply

-

✅ Highly skilled engineering team with dedicated support

-

✅ Fast delivery and nationwide technical services

Contact Us for a Free Consultation

📞 Hotline: +84 909 123 456

🌐 Website: www.pm-e.vn

📧 Email: sales@pm-e.vn

Phuc Minh Industrial Valves – Your trusted partner in industrial steam solutions!

Related News

VinVal Industrial Water Valves: Stainless Steel Globe Valves & Pipeline Solutions from PM-E

20/12/2025

Discover high-quality VinVal industrial water valves. PM-E specializes in providing stainless steel globe valves and diverse fluid control solutions for your pipeline systems.

Steam Energy-Saving Solutions for Factories | Phuc Minh Engineering

17/12/2025

Optimize your steam system with Phuc Minh Engineering. Reduce energy loss, increase boiler efficiency, and cut fuel costs by 10–30%. Contact us now.

Flow Measurement & Pressure Control Solutions.

17/12/2025

Solutions for measuring flow and controlling pressure in steam, air, water, oil, and chemical systems. Optimize operations – reduce losses – enhance safety. Contact Phuc Minh.

What Is a Pressure Reducing Valve? Structure – Working Principle – How to Select the Best PRV for Industrial Plants (2025)

17/12/2025

A Pressure Reducing Valve (PRV) is a device used to reduce high inlet pressure to a stable, lower outlet pressure, helping protect piping systems, instruments, and machinery while improving operational safety. PRVs are widely used in: Steam systems Compressed air, gas, nitrogen Clean water – process water – chilled water Oil, chemicals, and other industrial media

Safety Valve For Steam Systems: Structure, Operation Principles & Selection Guide 2025 | Phuc Minh Engineering

17/12/2025

Learn what a steam safety valve is, how it works, different types, and how to select the correct valve for boilers and pipelines. EN/ASME-standard valves from Phuc Minh Engineering.

.png)