SAFE TANK PROTECTION – OPTIMIZED PRESSURE CONTROL

SAFE TANK PROTECTION – OPTIMIZED PRESSURE CONTROL

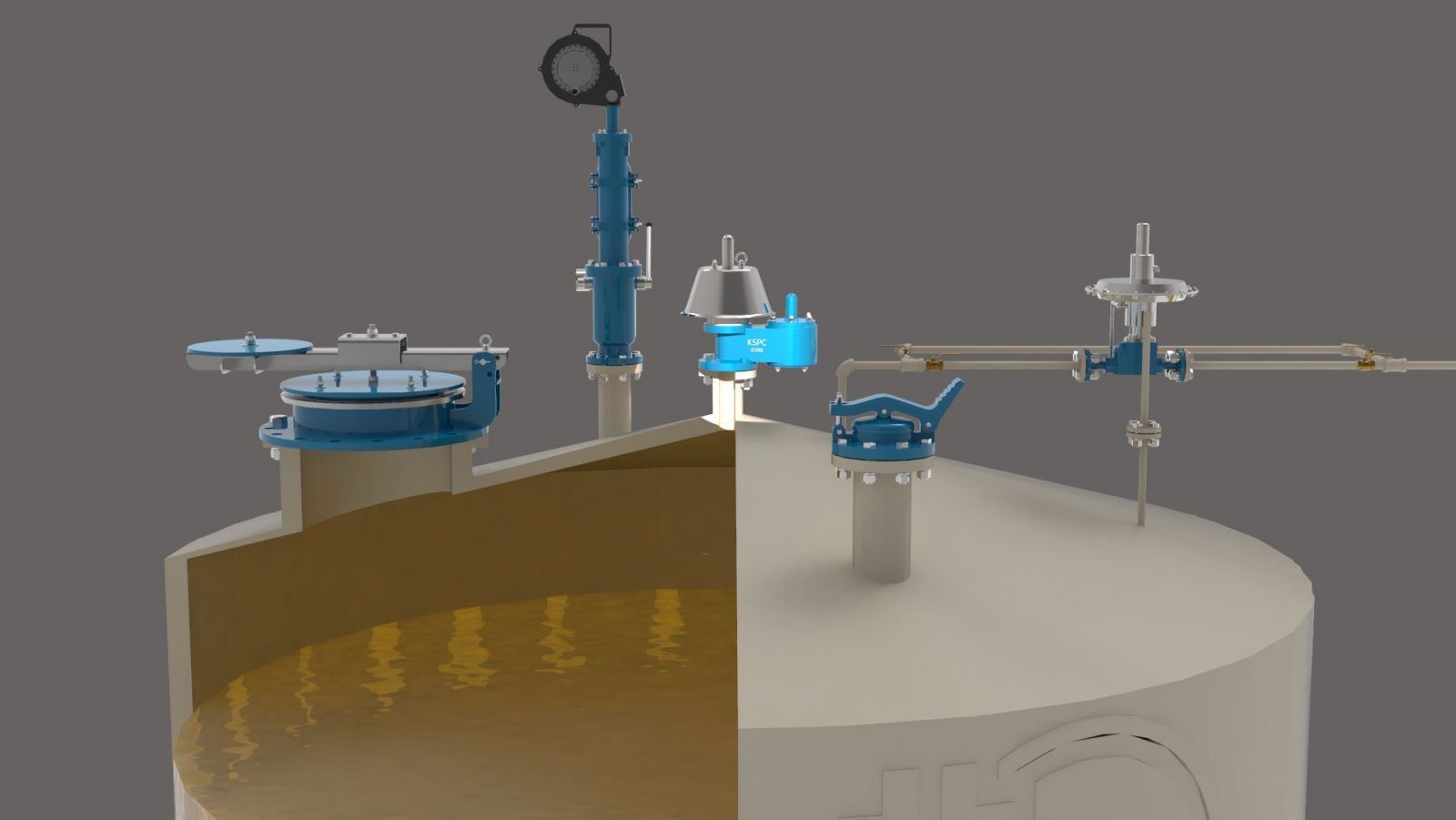

KSPC BREATHER VALVE – LEADING SOLUTION FROM KOREA

For chemical, fuel, edible oil storage tanks and similar systems:

-

Sudden pressure increase or decrease can cause tank deformation, explosion, or denting.

-

Loss of fuel, water, edible oil vapors leads to resource waste.

-

Release of toxic chemical vapors pollutes the environment and endangers human health.

Comprehensive Solution:

BREATHER VALVE – KSPC, KOREA

OUTSTANDING ADVANTAGES OF KSPC BREATHER VALVES:

-

Automatic pressure balancing: Maintains tank stability and safety.

-

Capable of collecting and treating harmful vapors.

-

High tightness – Accurate venting: Meets API 2000 standard.

-

Wide range of materials: SS304, SS316, Aluminum, Carbon Steel, Teflon Seat—suitable for highly corrosive environments.

-

Superior durability: Stable performance under harsh industrial conditions.

-

Flexible customization: According to required pressure, flow rate, and tank size.

WIDELY USED IN:

-

Refineries, chemical plants, food processing, pharmaceuticals...

-

(Fuel tanks, edible oil tanks, palm oil tanks, chemical tanks, gas-tight tanks, etc.)

Official Importer – With CO/CQ Certificates – Free Technical Consultation

SAFE TANK PROTECTION – OPTIMIZED PRESSURE CONTROL

KSPC BREATHER VALVE – LEADING SOLUTION FROM KOREA

For chemical, fuel, edible oil storage tanks:

-

Sudden pressure changes can deform, dent, or even explode the tank.

-

Vapor loss (fuel, water, edible oil...) leads to wasted resources.

-

Toxic vapor emissions pollute the environment and pose health risks.

Comprehensive Solution:

BREATHER VALVE – KSPC, KOREA

KEY BENEFITS OF KSPC BREATHER VALVES:

-

Automatic pressure balancing: Ensures tank stability and safety.

-

Capable of collecting and treating harmful vapors.

-

High sealing performance – precise venting: API 2000 compliant.

-

Various materials: SS304, SS316, Aluminum, Carbon Steel, Teflon Seat... for corrosive environments.

-

Superior durability: Reliable operation under tough industrial conditions.

-

Flexible customization: Tailored to pressure, flow, and tank size requirements.

%20-3.jpg)

WIDELY USED IN:

-

Refineries, chemical plants, food, pharmaceutical industries...

(Fuel tanks, edible oil tanks, palm oil tanks, chemical tanks, gas-tight tanks...)

Official Importer – CO/CQ Certificates Available – Free Technical Consultation

Contact us now for technical consultation and accurate pricing!

Official Authorized Agent in Vietnam:

PHUC MINH ENGINEERING CO., LTD

Website: www.pm-e.vn | www.kspc.net.vn | www.phucminh.net

Zalo/Phone: +84 902 72 08 14 | +84 907 45 05 06 | +84 90 28 007 28 | +84 979 73 73 51 | +84 766 22 61 61 | +84 902 601 875

Tel: +84 28-3535 2125 | Fax: +84 28-3535 0254

Email:

info@pm-e.vn | info@kspc.com.vn

sales@pm-e.vn | duong@pm-e.vn | vinh@pm-e.vn

Phuc Minh provides free technical consultation, on-site installation and maintenance support, and always maintains stock availability to promptly serve all projects.

Related News

VinVal Industrial Water Valves: Stainless Steel Globe Valves & Pipeline Solutions from PM-E

20/12/2025

Discover high-quality VinVal industrial water valves. PM-E specializes in providing stainless steel globe valves and diverse fluid control solutions for your pipeline systems.

Steam Energy-Saving Solutions for Factories | Phuc Minh Engineering

17/12/2025

Optimize your steam system with Phuc Minh Engineering. Reduce energy loss, increase boiler efficiency, and cut fuel costs by 10–30%. Contact us now.

Flow Measurement & Pressure Control Solutions.

17/12/2025

Solutions for measuring flow and controlling pressure in steam, air, water, oil, and chemical systems. Optimize operations – reduce losses – enhance safety. Contact Phuc Minh.

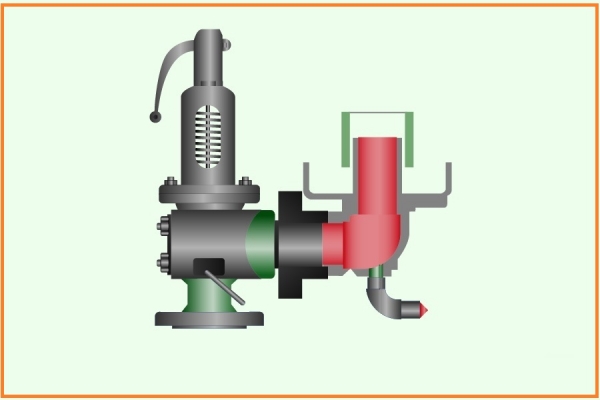

What Is a Pressure Reducing Valve? Structure – Working Principle – How to Select the Best PRV for Industrial Plants (2025)

17/12/2025

A Pressure Reducing Valve (PRV) is a device used to reduce high inlet pressure to a stable, lower outlet pressure, helping protect piping systems, instruments, and machinery while improving operational safety. PRVs are widely used in: Steam systems Compressed air, gas, nitrogen Clean water – process water – chilled water Oil, chemicals, and other industrial media

Safety Valve For Steam Systems: Structure, Operation Principles & Selection Guide 2025 | Phuc Minh Engineering

17/12/2025

Learn what a steam safety valve is, how it works, different types, and how to select the correct valve for boilers and pipelines. EN/ASME-standard valves from Phuc Minh Engineering.

.png)