SAFE TANK PROTECTION – OPTIMIZED PRESSURE CONTROL

SAFE TANK PROTECTION – OPTIMIZED PRESSURE CONTROL

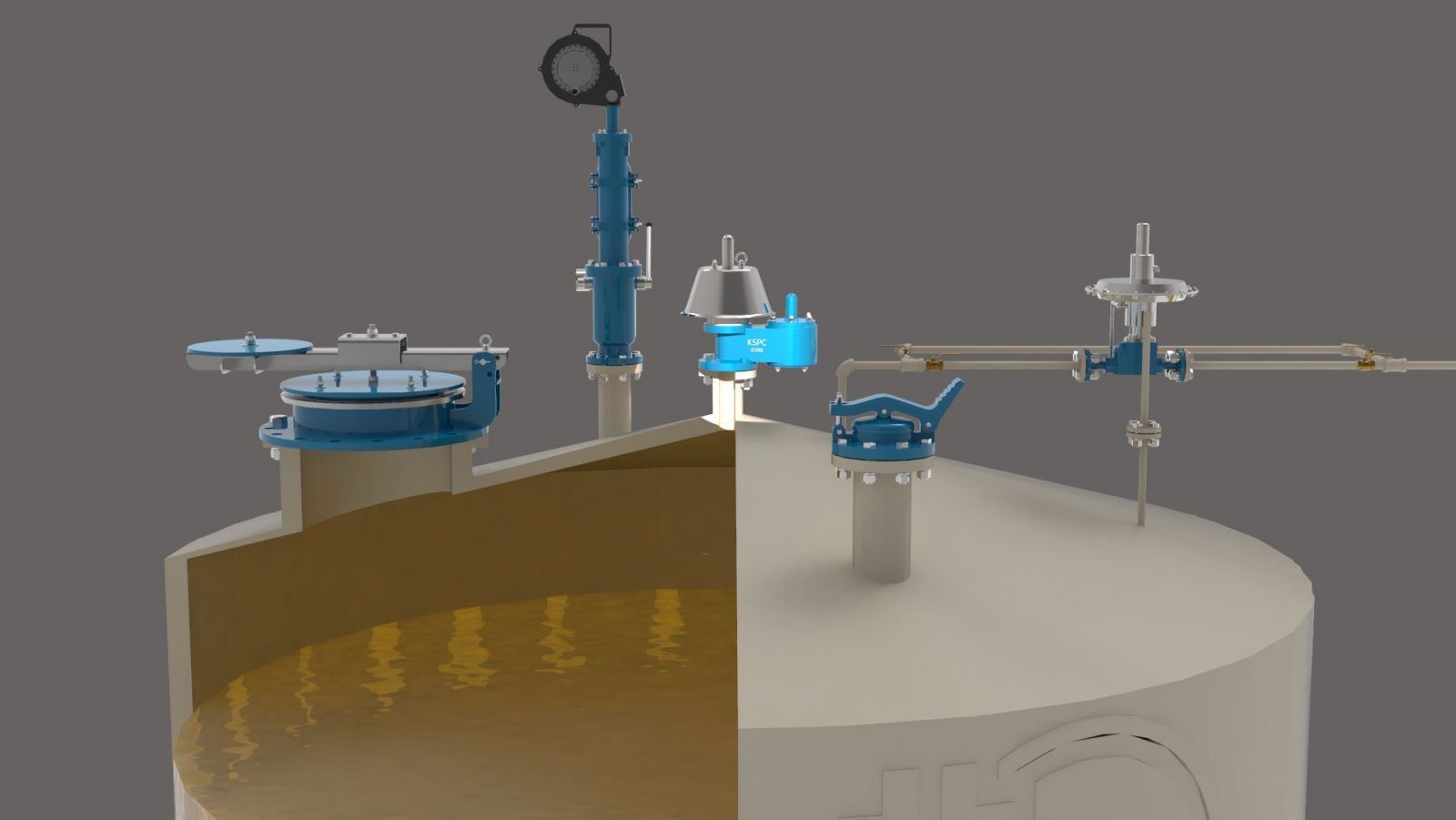

KSPC BREATHER VALVE – LEADING SOLUTION FROM KOREA

For chemical, fuel, edible oil storage tanks and similar systems:

-

Sudden pressure increase or decrease can cause tank deformation, explosion, or denting.

-

Loss of fuel, water, edible oil vapors leads to resource waste.

-

Release of toxic chemical vapors pollutes the environment and endangers human health.

Comprehensive Solution:

BREATHER VALVE – KSPC, KOREA

OUTSTANDING ADVANTAGES OF KSPC BREATHER VALVES:

-

Automatic pressure balancing: Maintains tank stability and safety.

-

Capable of collecting and treating harmful vapors.

-

High tightness – Accurate venting: Meets API 2000 standard.

-

Wide range of materials: SS304, SS316, Aluminum, Carbon Steel, Teflon Seat—suitable for highly corrosive environments.

-

Superior durability: Stable performance under harsh industrial conditions.

-

Flexible customization: According to required pressure, flow rate, and tank size.

WIDELY USED IN:

-

Refineries, chemical plants, food processing, pharmaceuticals...

-

(Fuel tanks, edible oil tanks, palm oil tanks, chemical tanks, gas-tight tanks, etc.)

Official Importer – With CO/CQ Certificates – Free Technical Consultation

SAFE TANK PROTECTION – OPTIMIZED PRESSURE CONTROL

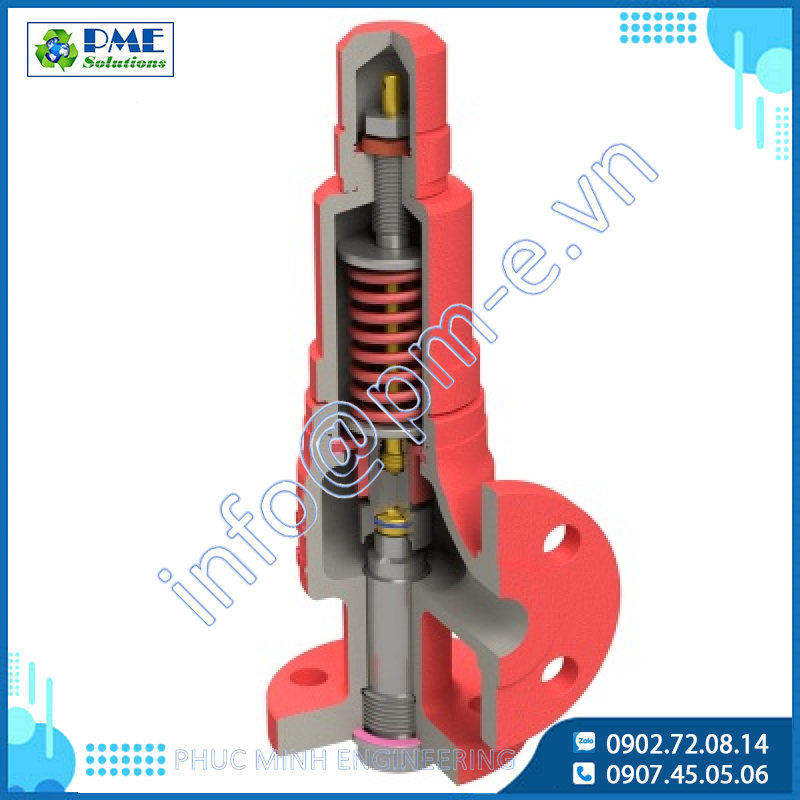

KSPC BREATHER VALVE – LEADING SOLUTION FROM KOREA

For chemical, fuel, edible oil storage tanks:

-

Sudden pressure changes can deform, dent, or even explode the tank.

-

Vapor loss (fuel, water, edible oil...) leads to wasted resources.

-

Toxic vapor emissions pollute the environment and pose health risks.

Comprehensive Solution:

BREATHER VALVE – KSPC, KOREA

KEY BENEFITS OF KSPC BREATHER VALVES:

-

Automatic pressure balancing: Ensures tank stability and safety.

-

Capable of collecting and treating harmful vapors.

-

High sealing performance – precise venting: API 2000 compliant.

-

Various materials: SS304, SS316, Aluminum, Carbon Steel, Teflon Seat... for corrosive environments.

-

Superior durability: Reliable operation under tough industrial conditions.

-

Flexible customization: Tailored to pressure, flow, and tank size requirements.

%20-3.jpg)

WIDELY USED IN:

-

Refineries, chemical plants, food, pharmaceutical industries...

(Fuel tanks, edible oil tanks, palm oil tanks, chemical tanks, gas-tight tanks...)

Official Importer – CO/CQ Certificates Available – Free Technical Consultation

Contact us now for technical consultation and accurate pricing!

Official Authorized Agent in Vietnam:

PHUC MINH ENGINEERING CO., LTD

Website: www.pm-e.vn | www.kspc.net.vn | www.phucminh.net

Zalo/Phone: +84 902 72 08 14 | +84 907 45 05 06 | +84 90 28 007 28 | +84 979 73 73 51 | +84 766 22 61 61 | +84 902 601 875

Tel: +84 28-3535 2125 | Fax: +84 28-3535 0254

Email:

info@pm-e.vn | info@kspc.com.vn

sales@pm-e.vn | duong@pm-e.vn | vinh@pm-e.vn

Phuc Minh provides free technical consultation, on-site installation and maintenance support, and always maintains stock availability to promptly serve all projects.

Related News

Composite Hose – Leading Anti-Corrosion, Chemical-Resistant Flexible Hose Solution in Vietnam

11/08/2025

High-quality imported composite hose, resistant to corrosion, chemicals, oils, and solvents. Available in Vietnam at competitive prices, full size range, and fast delivery.

Comprehensive Valve and Process Control Solutions for Key Industries

16/07/2025

Water Treatment Industry – Scale and Challenges Water treatment is a vital sector, ensuring safe water supply for both residential and industrial use. As urbanization and industrialization accelerate, water treatment systems must meet increasingly stringent requirements: Ensure output water quality meets national and international standards. Maintain continuous, stable operation while minimizing unexpected downtime. Optimize energy efficiency and reduce operational and maintenance costs. Integrate monitoring and automation for enhanced remote control and management. Comply with strict environmental protection regulations and carbon emission reduction goals.

Korea Industrial Valve?

15/07/2025

Industrial valves play a crucial role in ensuring the smooth operation of modern pipeline systems, from large-scale manufacturing plants to daily water supply systems. They help control flow, regulate pressure, and protect equipment, contributing to safe and efficient system operation. In this article, Phuc Minh Engineering—a leading distributor of genuine industrial valves in Vietnam—will help you better understand industrial valves: their definition, classification, operating principles, and real-world applications. What Is an Industrial Valve? An industrial valve is a mechanical device installed in pipelines to control the flow of fluids. Fluids can include liquids (water, oil, chemicals), gases (compressed air, gas), or even slurry and powder. Main Functions of Industrial Valves: Fully open/close fluid flow Regulate fluid flow rate Adjust system pressure, protect equipment Switch flow direction Prevent incidents such as overpressure or backflow Phuc Minh Engineering offers expert consultation on selecting the right valve to optimize system efficiency, reduce operating costs, and extend equipment lifespan.

Kitz Valves – Top-Quality Industrial Valves from Japan

15/07/2025

Kitz Valves are a leading industrial valve brand from Japan, widely trusted in Vietnam across factories, industrial zones, water supply projects, oil & gas, and chemical industries. Thanks to outstanding quality, high durability, and a wide product range, Kitz valves are always among the first choices for MEP engineers. 1️⃣ What Are Kitz Valves? Kitz Valves are manufactured by Kitz Corporation of Japan—one of the largest industrial valve manufacturers worldwide. Kitz is renowned for strict production standards, consistent quality, and long product lifespan. Key Advantages: 100% made in Japan or by Kitz Group factories Wide material options: cast iron, bronze, stainless steel, forged steel, plastic High pressure and temperature resistance Long service life, smooth operation, easy maintenance

What Is an Industrial Valve? Types, Applications, and How It Works

14/07/2025

Industrial valves may seem like small components, but they play an essential role in the operation of countless modern piping systems. From large-scale manufacturing plants to residential water supply and drainage systems, industrial valves are always present, performing critical functions that help control fluid flow safely and efficiently. So, what exactly is an industrial valve? What types are there? How do they operate, and in which industries are they commonly applied? Let’s explore these questions in detail with Phuc Minh Engineering in the article below.

.png)