Butterfly Valve

Price: Contact

401N - Double offset butterfly valves 401N series.

| Size range | 3” ÷ 56” (DN80 ÷ DN1400) |

| Type | Wafer, Lug, Double flanged on request |

| Design | ASME B16.34, EN 12516-2, EN 593 |

| Face to face | API 609, EN 558 |

| Operating temperature | -40°C + 220°C (-40 °F ÷ +428 °F) |

| Pressure ratings | ASME class 150 – bidirectional |

| Flange drilling | ASME B16.5, ASME B16.47 series A, EN1092-1 |

| Testing | API 598, EN 12266-1 |

| Leakage class | Rate “A” – No leakage – according to EN 12266-1 |

| Standard materials | Body: Ductile Iron, Carbon Steel, Stainles Steel |

| Disc: Ductile Iron, Carbon Steel, Stainles Steel | |

| Stem: AISI 304, AISI 316, AISI 630 | |

| Seat: PTFE + Carbographite | |

| INCONEL 625 LCF on request for metal to metal seated | |

| Applications | Chemical and Pharmaceutical industries, sistems for solvent recovery, |

| other applications with compatible materials to working conditions | |

| Certifications | 97/23/CE PED, 94/9/CE ATEX, Fire Safe API 607, ISO 10497, API 6FA (on request) |

| SIL – IEC 61508, IEC 61511, GOST-R, CU TR 10 – CU TR 32 |

Introduction: Double Eccentricity Butterfly Valve Series 401N

This is a new range of butterfly valves of the double eccentricity type with “bubble tight” seal, designed for heavy duty service, especially as regards to shipbuilding and petrochemical sectors.

Above all it is ideal for shut-off and/or flow control of aggressive fluids or gases.

Awide variety ofmaterials can be used tomake the valve; those falling, in the standard range are.

- Ductile Iron (only fromND350 and bigger size)

- CarboonSteel

- StainlessSteel

- Aluminium Bronze (only on request)

Such valves are manufactured according to the most up-to date design criteria, thereby offering maximum guarantee of correct operation and minimum maintenance.

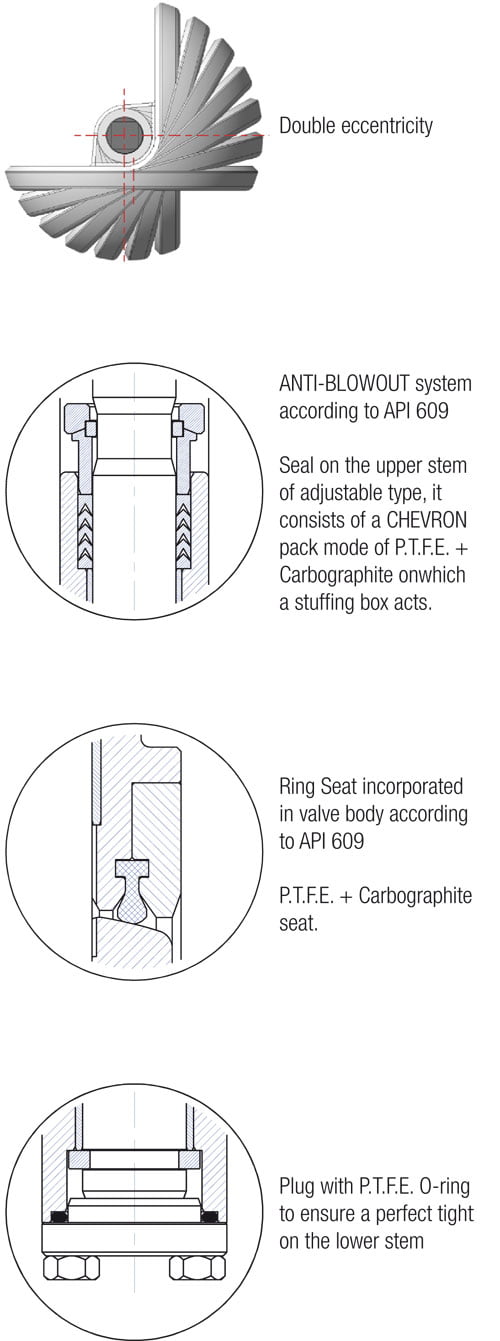

Constructive features

The valve body is of WAFER type with 4 centering holes for facilitating the mounting between the flanges or else of LUG type with threaded or throught lugs when the valve is to be used as a foot valve.

The butterfly disc is of the double eccentricity type. This design feature ensures a particularly favourable affect either for flow control or in the opening and closing movement. In fact, the butterfly disc has two surfaces which are different from the degree of the valve opening. This results in a moment of rotation which prevents any possible valve floating.

The seal on the upper stemis of the adjustable type and consist of a CHEVRON pack mode of P.T.F.E. + Carbographite, on which a stuffing box acts. When the stem seal requires replacement, such operation can be performed without having to remove the valve from the piping.

The stem is made from ‘h8’ ground bar, and besides being guided by c.s. + P.T.F.E. or s.s. + P.T.F.E. PAP bushings, it guarantees a perfectly tight shutt-off on the stuffing box. The stem is integral with the butterfly disc throught parallel key and tapered pins. A plug with P.T.F.E. O-ring ensures perfectly tight seal on the lower stem.

The seat retaining ring is embedded in the body, according to API 609, and it serves to keep the valve seat in its place. A phonographic groove is machined on the outside of the ring to ensure tight shutt-off between the valve and the flange through a common seal.

The seat is a drop-shaped section solid P.T.F.E. + Carbographite profile, which is in direct contact with the process fluid. Thanks to this solution, the seat can be replaced without having to fully disassemble the valve fromthe piping.

Related projects

.png)