Electronic Control Valves

Price: Contact

Series 22 - Electronic Control Valves

The development and proliferation of SCADA, CAN, Intranet, and Cellular systems has increased the requirement for electronically controlled valves that interface with these systems. The OCV Series 22 Digital Control Valves were specifically designed for this task. While retaining the advantages of simplicity and line pressure operation, these valves offer an ease of operation and degrees of flexibility not previously achieved.

- Electronic Glossary

- Model 22VMU Flow Measurement and Flow Control System

- Model 22X Electronic Position Control Valve

- Model 22F Electronic Flow Control

- Model 22R Electronic Pressure Reducing

- Model 22S Electronic Pressure Sustaining

- ValveMeter Lite Flow Measurement System

Valve Features

THE CONTROLS

The OCV “Universal Valve Controller” (UVC) is a series that has been built and designed to provide numerous control functions for the OCV control valve. In addition, the UVC can be customized for specific user requirements.

FEATURES OF UVC CONTROLLERS

- Field upgradeable-Should system require

- Process Variable Input

- Analog (0-10V, 4-20mA)

- Digital (pulse)

- Remote Access / Communication (SCADA)

- 4-20mA for Remote Set Point

- RS232/RS485 Communication Port

- Internal Real Time Clock

- Time, Day of Week

- Enclosure: NEMA 4X (IP66)

- Electronic Controllers are UL Listed

- Operational Power

- 110-250 VAC, 50/60 Hz (less than 30 Watts

- Battery backup and DC Models are available-consult factory

- Power Saving Options

- Adjustable Display Activities

- Adjustable Solenoid Activation Cycle Time (where applicable)

In addition to the above features, two upgrade models are available. They include all of the above options, plus what is listed below.

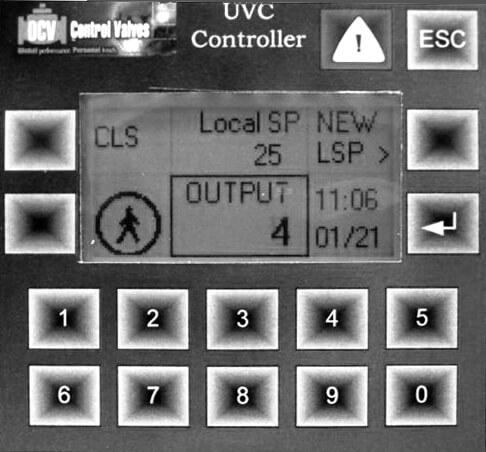

UVC BASIC

*Display may vary

Features of the UVC Basic:

- 128X64 Graphic Monochrome Display

- 15 Keys for entry and scrolling

Special Optional Features:

- Analog Output (4-20mA)

- Additional Discrete Inputs and Outputs

- SMS (text) Messaging by GSM Modem

UVC Basic Typical Applications:

- Pressure Control

- Level/Altitude Control

- Flow Control with External Flow Meter

- Flow Metering

- Consult factory for others

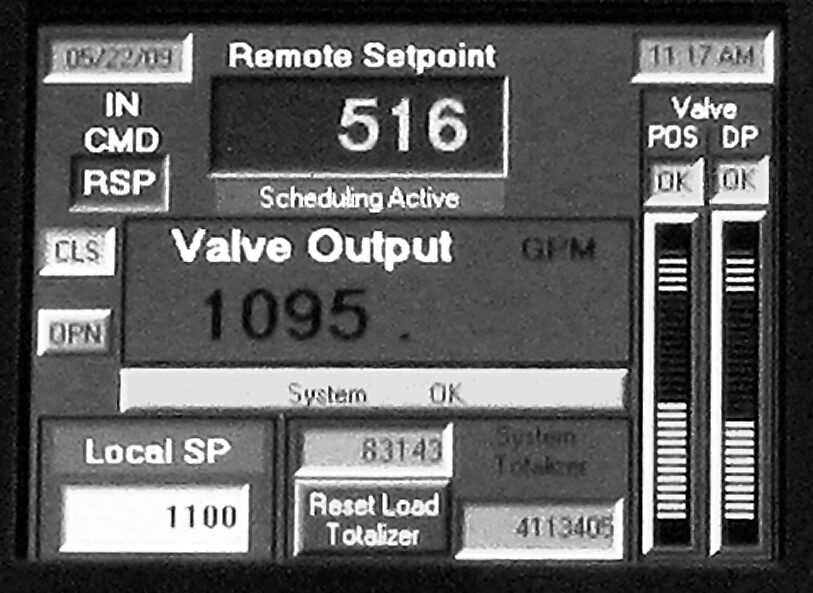

UVC ULTRA

*Display may vary

Specific Features of the UVC Ultra:

- 320X240 Color Graphic Display

- 5 Keys and Virtual Keyboards

- Touch Screen

- Logging Capabilities

Special Optional Features:

- Analog Output (4-20mA)

- MODBUS Protocol Support

- Additional Discrete Inputs and Outputs

- SMS (text) Messaging by GSM Model

- Ethernet Communications

- Email generation upon valve errors; sends to 1-5 email addresses

UVC Ultra Typical Applications:

- Pressure Control

- Level/Altitude Control

- Flow Control without External Flow Meter

- Flow Metering

- Consult factory for others

Valve Operation

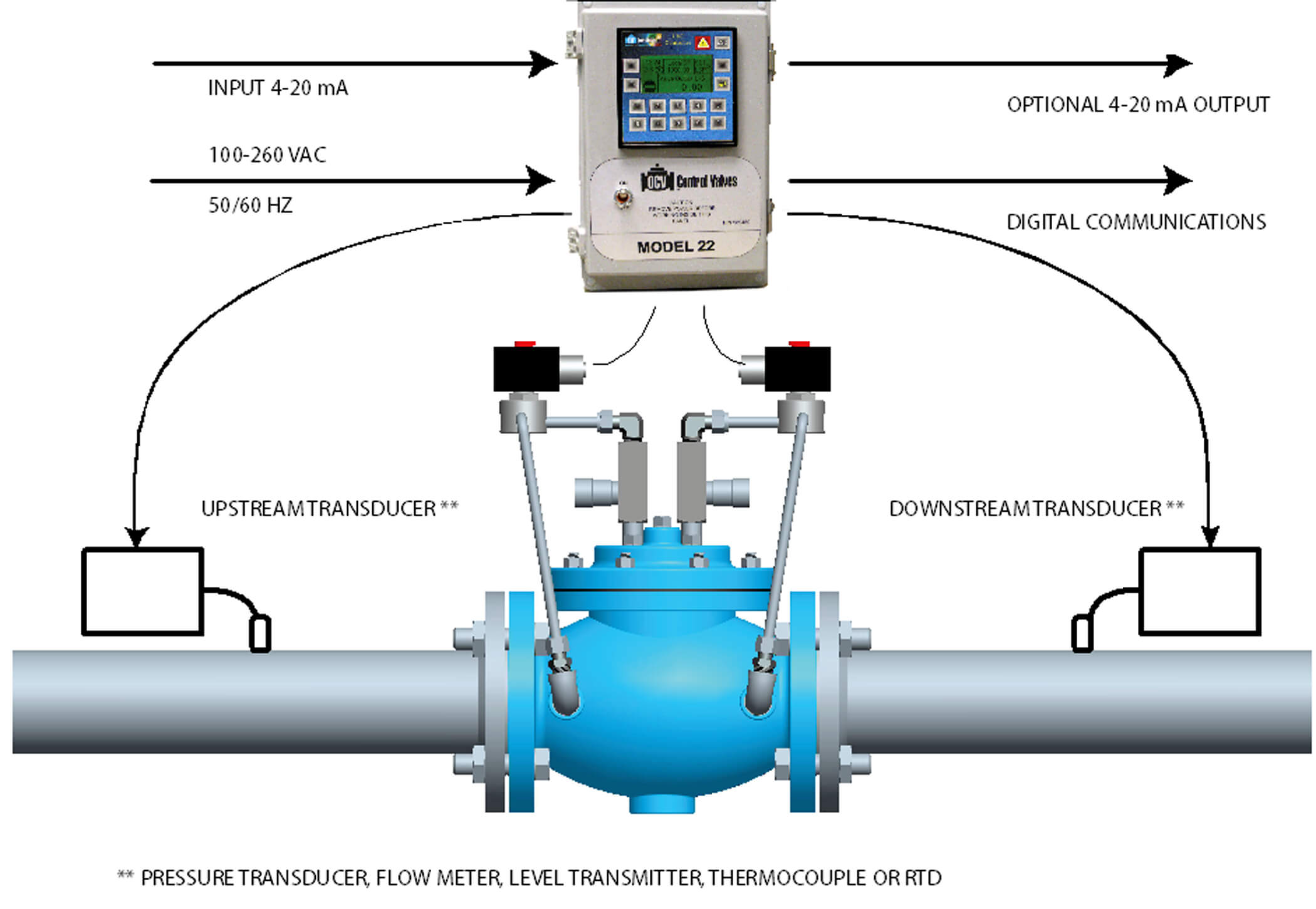

OPERATING PRINCIPLES OF THE SERIES 22 CONTROL VALVE

The system consists of:

- Universal Controller (UVC)

- Process Transducer(s)

- Model 115-3, hydraulically operated, dual solenoid controlled valve

- Valve Position Transmitter-required on some valves, optional on others

UVC Valve Controller

The UVC Controller is the electronic brains of the system. It is a highly sophisticated electronic module whose purpose is to control a process variable (flow, pressure, etc). The UVC receives input, compares it to the desired control setting and then sends electrical power to the valve solenoids until the desired setting is reached.

Model 115-3 Control Valve

The 115-3 valve is the dual solenoid, diaphragm actuated control valve for the series 22 electronic control valve. It is positioned by its two solenoid pilots (2) and (3). With pilot (2) closed and pilot (3) open, the diaphragm chamber of the main valve (1) in vented to downstream and the valve moves further open at an adjustable rate. Conversely, with pilot (2) open and pilot (3) closed, inlet pressure is applied to the main valve diaphragm chamber, moving the valve further closed at an adjustable rate. Finally, with both pilots closed, the diaphragm chamber is “hydraulically locked” (no flow on or off the chamber) and the valve holds its position. The 115-3 valve can be ordered with normally open, or normally closed pilots. In the event of failure, the valve will close, open or hold its last position depending on which failure position is specified.

UVC Operation with Valve

The UVC receives a signal (PV) from the process transducer and compares it to the programmed set point. If the PV is outside of the small dead band around the set point, the controller begins pulsing the appropriate solenoid pilot open and closed on a time proportional basis, with the amount of open time directly proportional to the deviation from the set point. Hydraulic locking occurs when the process variable is within the dead band around the set point. The pulsing action enables the set point to be maintained within close limits, with a minimum of overshoot or “hunting” when process conditions change. The locking action gives the valve extreme stability, even at highly throttled (low flow) positions. The UVC can be configured to either close, open or hold last position in the event input signal failure.

Valve Position Transmitter

The valve position transmitter (optional) uses movement of the valve stem to provide a 4-20mA analog signal proportional to the valve position. The signal increases as the valve opens. Mounted to the center port of the valve bonnet, a rod is threaded into the main valve stem. The valve position transmitter may be installed on virtually any OCV Control Valve without disassembly of the valve itself.

Process Transducer

A Process Transducer is a device that converts pressure flow, temperature, or level to an electrical measurement (e.g., Volts, Milliamps, frequency or pulses).

Related projects

.png)