INTRODUCTION TO DANTEC COMPOSITE HOSES – UK

INTRODUCTION TO DANTEC COMPOSITE HOSES – UK

& OFFICIAL AUTHORIZED DISTRIBUTOR IN VIETNAM: PHUC MINH ENGINEERING CO., LTD

-

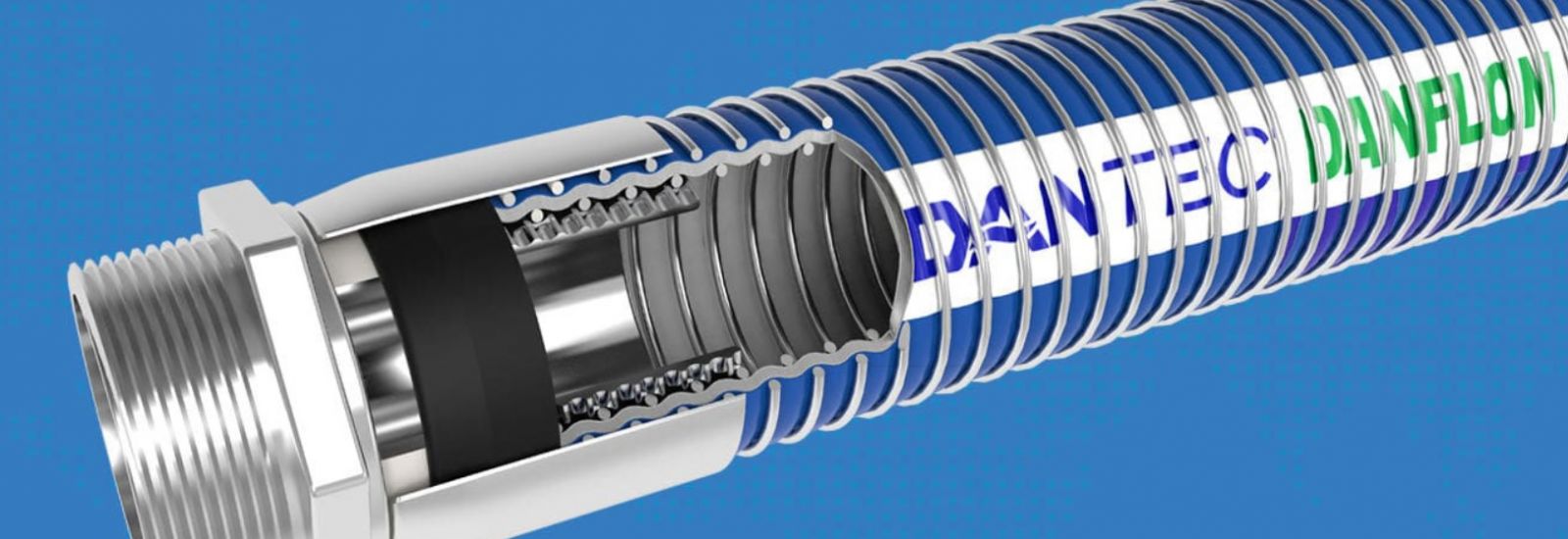

About Dantec – The World’s Leading Composite Hose Manufacturer

Founded in 1969 in the United Kingdom, Dantec Ltd is recognized as one of the world’s most advanced composite hose manufacturers, exporting products to over 60 countries.

Originally starting as a gasket-cutting business, Dantec diversified into industrial products, especially composite hoses, in 1977 to meet the stringent requirements of the UK’s largest petrochemical complex at Ellesmere Port. Continuous innovation and development have positioned Dantec as a global leader in composite hose technology.

All products are manufactured at Dantec’s purpose-built facility in Northern England, using high-specification materials and strict international quality standards. Dantec’s hoses ensure outstanding durability, safety, and performance for industrial applications.

-

Global Distribution System & Official Distributor in Vietnam

Dantec operates its headquarters and manufacturing plant in Moreton, Merseyside, UK, supported by a network of trained distributors worldwide.

In Vietnam, Dantec has officially appointed:

PHUC MINH ENGINEERING CO., LTD (PME)

Official Authorized Distributor of Dantec Composite Hoses in Vietnam.

Contact Information:

-

Hotline/Zalo: +84 902 720 814 – +84 907 450 506

-

Tel: +84 28 3535 2125

-

Email: info@pm-e.vn

-

Website: www.pm-e.vn

Phuc Minh Engineering imports directly from the UK and provides:

-

CO (Certificate of Origin)

-

CQ (Certificate of Quality)

-

Original Test Reports and Material Test Certificates upon order.

-

Main Applications of Dantec Composite Hoses

Dantec composite hoses are widely used in key industries such as oil & gas, chemical transportation, hazardous liquids handling, and food-grade applications. Typical applications include:

-

Ship to Shore Hose

-

Ship to Ship (STS) Transfer Hose

-

Snake Pit Hose

-

Tank to Tank Transfer Hose

-

Bottom Loading Hose

-

Tower Hose

-

Tank Terminal Hose

-

Rail Car Refuelling Hose

-

Road Tanker Hose

-

Roof Drain Hose

-

Pivot Hose

-

Framo Pump Hose

-

Cross Over Prevention Hose (COPsafe)

-

In-Plant Transfer Hose

-

Chemical Transfer Hose

-

Oil Transfer Hose

-

LPG Transfer Hose

-

Vapour Recovery Hose

-

Vapour Return Hose

-

Formula 1 Refuelling Hose

-

Jumper Hose

-

Commitment from Phuc Minh Engineering

-

100% Genuine Dantec UK Products

-

Full set of CO, CQ, International Quality Certificates

-

Competitive Pricing, Professional Technical Support

-

Consultation on model selection tailored to actual application needs

For project consultation, product quotation, or technical support regarding Dantec composite hoses in Vietnam, please contact Phuc Minh Engineering directly.

Related News

VinVal Industrial Water Valves: Stainless Steel Globe Valves & Pipeline Solutions from PM-E

20/12/2025

Discover high-quality VinVal industrial water valves. PM-E specializes in providing stainless steel globe valves and diverse fluid control solutions for your pipeline systems.

Steam Energy-Saving Solutions for Factories | Phuc Minh Engineering

17/12/2025

Optimize your steam system with Phuc Minh Engineering. Reduce energy loss, increase boiler efficiency, and cut fuel costs by 10–30%. Contact us now.

Flow Measurement & Pressure Control Solutions.

17/12/2025

Solutions for measuring flow and controlling pressure in steam, air, water, oil, and chemical systems. Optimize operations – reduce losses – enhance safety. Contact Phuc Minh.

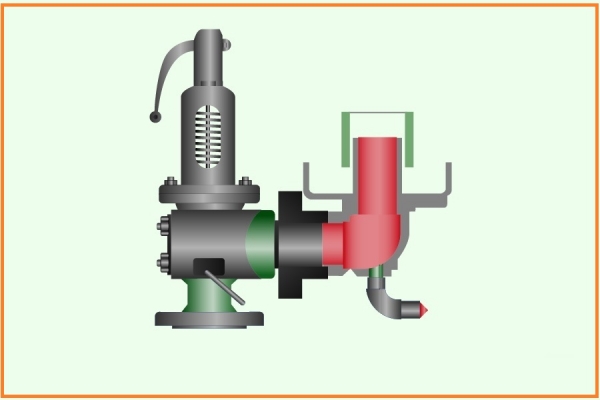

What Is a Pressure Reducing Valve? Structure – Working Principle – How to Select the Best PRV for Industrial Plants (2025)

17/12/2025

A Pressure Reducing Valve (PRV) is a device used to reduce high inlet pressure to a stable, lower outlet pressure, helping protect piping systems, instruments, and machinery while improving operational safety. PRVs are widely used in: Steam systems Compressed air, gas, nitrogen Clean water – process water – chilled water Oil, chemicals, and other industrial media

Safety Valve For Steam Systems: Structure, Operation Principles & Selection Guide 2025 | Phuc Minh Engineering

17/12/2025

Learn what a steam safety valve is, how it works, different types, and how to select the correct valve for boilers and pipelines. EN/ASME-standard valves from Phuc Minh Engineering.

.png)