HIGH-TEMPERATURE GASKETS – UP TO 1000°C WITH THERMa-PUR™ 4122 MATERIAL

HIGH-TEMPERATURE GASKETS – UP TO 1000°C WITH THERMa-PUR™ 4122 MATERIAL

In many heavy industries such as chemical processing, oil refining, cement, and power generation, sealing materials must endure extreme temperatures, high pressure, and harsh oxidative environments.

Phuc Minh Engineering Co., Ltd. is proud to be a distributor of high-temperature gaskets rated up to 1000°C, combining Garlock’s advanced THERMa-PUR™ 4122 material with Corrugated Metal Gaskets (CMG) – delivering an optimal sealing solution for extreme industrial conditions.

1. THERMa-PUR™ 4122 – Advanced High-Temperature Sealing Material

🔥 Temperature resistance up to 1000°C (1832°F) – Engineered for continuous high-temperature service.

🛡️ Superior oxidation resistance – Unique formulation reduces material breakdown under high heat and corrosive conditions.

⚖️ Retains 95% of original weight – Compared to traditional vermiculite gaskets that lose up to 10% due to oxidation.

🌱 Solvent-free manufacturing process – Environmentally friendly with minimal contamination risk.

🔩 Garlock’s proprietary fiber core structure – Minimizes deformation and simplifies installation.

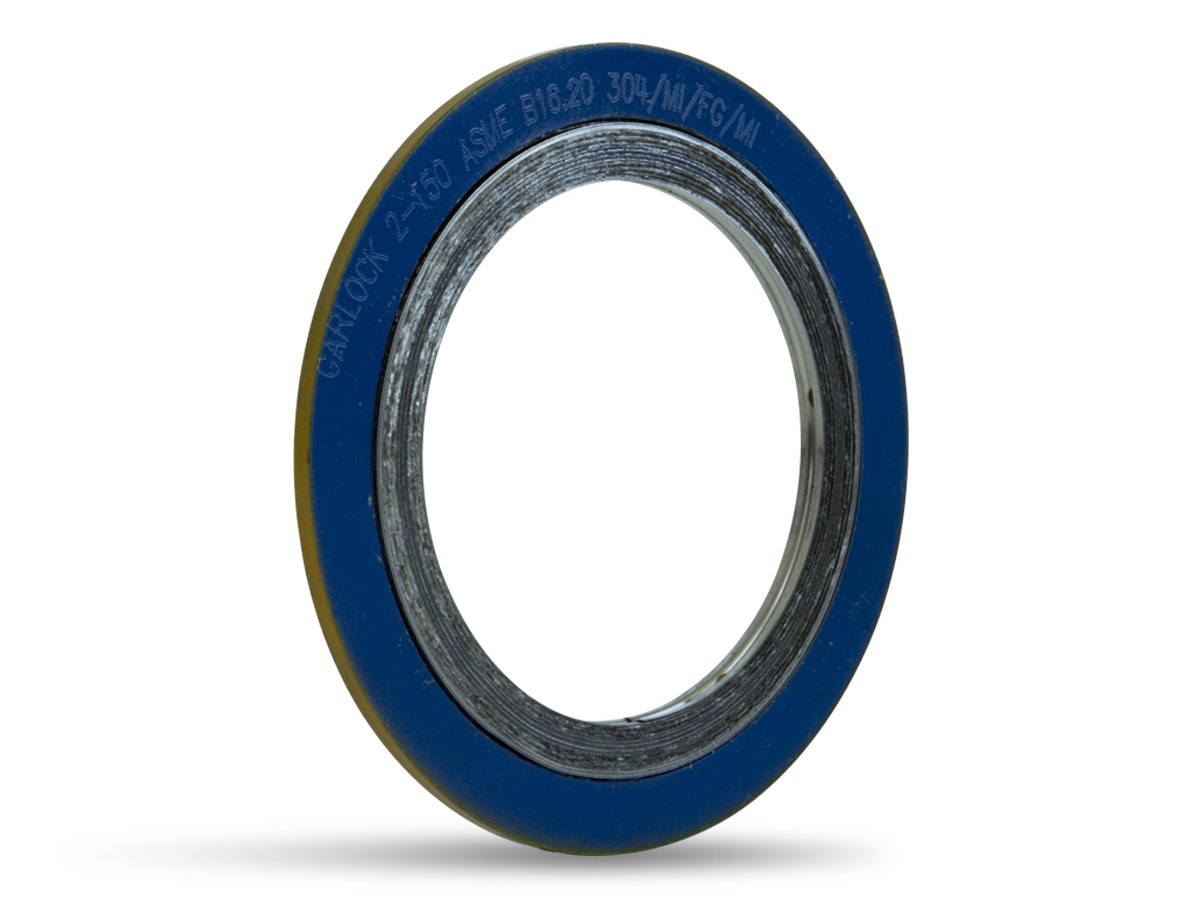

2. Combined Sealing Solution: CMG + THERMa-PUR™ 4122

The integration of THERMa-PUR™ 4122 and Corrugated Metal Gaskets (CMG) creates a high-performance gasket system capable of withstanding elevated temperature and pressure conditions:

✅ Enhanced sealing performance – Metal core offers resilience, THERMa-PUR™ ensures heat resistance.

✅ Reduced leakage risks – Dual-material structure maximizes overall sealing integrity.

✅ Naturally non-stick – THERMa-PUR™ facilitates easy removal and replacement.

✅ Flexible configuration – Compatible with various gasket types, especially 4122-CMG.

📌 Typical Applications

-

Power plants, cement kilns, oil & gas

-

Furnaces, combustion chambers

-

Heat exchangers, thermal pipelines

-

Pressurized systems requiring extreme sealing durability

Contact Phuc Minh – Your Trusted Sealing Expert

Phuc Minh Engineering Co., Ltd. is committed to delivering:

-

Genuine products from Garlock (USA)

-

Expert technical consultation from experienced engineers

-

Optimal solutions to enhance your system’s reliability and longevity

CONTACT INFORMATION

PHUC MINH ENGINEERING CO., LTD.

📍 92/38, Street No. 12, Binh Hung Hoa Ward, Binh Tan District, Ho Chi Minh City, Vietnam

📞 Hotline (Zalo): +84 902 720 814 – +84 907 450 506

📠 Tel: +84 28 3535 2125 – Fax: +84 28 3535 0254

📧 Email: info@pm-e.vn

🌐 Website: www.pm-e.vn

Related News

VinVal Industrial Water Valves: Stainless Steel Globe Valves & Pipeline Solutions from PM-E

20/12/2025

Discover high-quality VinVal industrial water valves. PM-E specializes in providing stainless steel globe valves and diverse fluid control solutions for your pipeline systems.

Steam Energy-Saving Solutions for Factories | Phuc Minh Engineering

17/12/2025

Optimize your steam system with Phuc Minh Engineering. Reduce energy loss, increase boiler efficiency, and cut fuel costs by 10–30%. Contact us now.

Flow Measurement & Pressure Control Solutions.

17/12/2025

Solutions for measuring flow and controlling pressure in steam, air, water, oil, and chemical systems. Optimize operations – reduce losses – enhance safety. Contact Phuc Minh.

What Is a Pressure Reducing Valve? Structure – Working Principle – How to Select the Best PRV for Industrial Plants (2025)

17/12/2025

A Pressure Reducing Valve (PRV) is a device used to reduce high inlet pressure to a stable, lower outlet pressure, helping protect piping systems, instruments, and machinery while improving operational safety. PRVs are widely used in: Steam systems Compressed air, gas, nitrogen Clean water – process water – chilled water Oil, chemicals, and other industrial media

Safety Valve For Steam Systems: Structure, Operation Principles & Selection Guide 2025 | Phuc Minh Engineering

17/12/2025

Learn what a steam safety valve is, how it works, different types, and how to select the correct valve for boilers and pipelines. EN/ASME-standard valves from Phuc Minh Engineering.

.png)