Sprinklers

Fire sprinkler (Sprinkler) – Phuc Minh imported directly

Sprinkler is a type of sprinkler head that spreads evenly over the fire area, each different type of nozzle is designed to work at each operating threshold and type of nozzle according to the type of structure of the nozzle body.

Each Sprinkler will operate individually when the pre-set trigger temperature is reached. Most Sprinkler nozzles spray around 80-100 liters/minute, this depends on the design of the system. Some special sprinklers are designed to allow spraying up to 400 liters per minute.

1. Structure and operating principle of the fire sprinkler Sprinkler

a. Structure Sprinkler

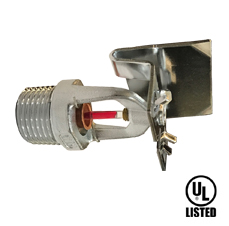

– Body: Creates a structure for the nozzle, to withstand the water pressure in the spray pipe. The body will hold the heat sensor and stopper to seal the water, supporting the sprinkler guide plate. Constructed of brass or chrome-plated steel to prevent rust. Choosing the right nozzle body type depends on the size of the area to be extinguished.

– Heat sensor: A temperature control element for water injection. At normal temperature, the sensor will block and hold the stopper to seal the water, when the temperature reaches the operating threshold, the sensor will release and drop the stopper. Usually the temperature sensor used is a glass bulb containing mercury.

– Stopper: Used to block and seal to prevent water from leaking out, blocked by the heat sensor to prevent water from spraying out. When the sensor works (broken or broken ...) the stopper will fall off and the water in the pipe will spray out.

– Guide plate: Mounted on the nozzle bar opposite the stopper where the water will spray out. The task of the guide plate is to evenly distribute the spray water and spread it over the surface of the fire fighting area. The guide plate determines the mounting pattern of the nozzle by the direction and angle of the spray. Common nozzle mounting styles are upward, downward, and horizontal. The installation of Sprinkler nozzles must be in accordance with the design, the selection of sprinkler type must be based on the architecture of the building.

The design of the sprintler nozzle normally consists of 3 parts:

The metal frame has a solid structure and a different size

The part of the heat collector is responsible for sensing the ambient temperature that affects the mercury bulb

The mercury bulb is like a tree, connected to a load-bearing cap that normally prevents water from escaping.

Each nozzle sprinkler works independently when a predetermined heat level is reached to the trigger temperature, number of nozzlessprinkler operation is limited so that only nozzles that are close to the fire will operate to help Maintaining water pressure at the nozzles near the fire helps to fight the fire more effectively.

b. Working principle of sprilker injector

The nozzle sprinkler works when the temperature changes, it will automatically open water directly on the fire, the operating temperature of the nozzle is fixed on each type of head, the operating principle is based on hot expansion when it encounters heat. the temperature of the glass bulb inside the sprinkler head is pushed out with the large pressure of the water flow directed by the fixed wing on the nozzle, which will directly affect the fire to control or completely extinguish the fire, Normally, the spray head is used to direct the water flow directly to the fire ( office area..) or the spray head is directed to the upward flow and then back to the fire ( used in garages, warehouses, etc.) ) only a certain number of nozzles operate in the event of a fire due to the response of the pumping system and safety standards, the system only activates when there is a relatively limited temperature change to a minimum of irritating conditions. animator.

Sprinkler nozzles have a color-coded activation temperature on the glass bulb of the nozzle, the corresponding activation temperature is a key issue in the operation and control of the system operating according to the requirements set forth, for For residential areas where safety is high, people use a injector type sprinkler quick response ( response time, triggering on very fast temperature changes )

2. Sprinkler standard – How to install sprinkler Sprinkler – Should it be mounted up or down?

Should I install the Injector Sprinkler facing up or down?

We would like to share some experience, it is possible to remove some floors without the sprinkler head design, if the ceiling area of that floor does not have many technical systems (only a few negative electrical pipes, small air ducts, etc.). small..), focus only on areas with many technical systems and technical floors on the commercial area.

It is the responsibility of the manufacturer to implement a quality control program to ensure that the manufacturer continually responds to the requirements in the same way as for the samples initially tested. Prior to testing, the nozzles shall be inspected and marked, for conformity to the manufacturer's drawings and for obvious defects.

Each automatic nebulizer must pass a leak resistance test equivalent to a hydrostatic pressure of at least 2.5 times the rated working pressure but not less than 3.0 MPa (30 bar) impact. for at least 2 s.

The nebulizer head shall be designed to seal its water contact surface for extended periods of time without leakage and open as intended, releasing all components from minimum operating pressures up to nominal working pressure, for nozzles for operating pressures of 1.2 MPa (12 bar) or less, sealing of the water contact face cannot be achieved using an O-ring dynamic or similar seal (O-ring or similar cuff that moves during operation or comes into contact with a moving part during operation).

The load on the heat-responsive element in automatic injectors shall be set by the manufacturer in such a way that field adjustment or replacement is prevented. The nozzle hole/direction must be permanently attached to the nozzle to prevent adjustment or replacement in the field.

All nozzles shall be designed so that a sphere with a diameter of 5 mm can pass through each water path in the nozzle. Nozzles with smaller holes must use a mesh filter (mesh) attached to each nozzle.

Mesh filters or nozzle filters shall be made of corrosion-resistant materials. The maximum size of a hole in a mesh filter or filter should not exceed 80% of the smallest protected hole diameter.

3. Nozzle classification Sprinkler

*Nozzles (nozzles)

– Automatic nozzle (automatic nozzle)

Heat sensitive device designed to react at a predetermined temperature by automatically discharging a water mist into a selected area and volume with a reaction time index (RTI) not greater than 50(m.s)1/2 and the coefficient of thermal conductivity (C) is not more than 1.0 (m/s)1/2.

– Coated nozzle

Coated nozzles for corrosion protection are carried out at the site of manufacture.

– Fast response nozzle

The automatic nozzle has a reaction time index (RTI) not greater than 50 (m.s)1/2 and a thermal conductivity coefficient (C) not greater than 1.0 (m/s)1/2.

– Fusible element nozzle

The nozzle is opened due to the melting of the part under the influence of heat.

– Glass bulb nozzle

The nozzle is opened due to the explosion of the bulb (fragile) because of the pressure caused by the expansion of the liquid contained in this bulb under the influence of heat.

– Multiple orific nozzle

Nozzle with two or more outlet openings arranged to distribute the discharge of water in a specified pattern and quantity to a defined protected area.

– Open nozzle (open nozzle)

The nozzle has no heat sensitive elements.

– The nozzle is pointing downwards (pendent nozzle)

The nozzle is constructed so that the mist is directed downward by impacting the distribution plate or by the directional plate.

– Upright nozzle (upright nozzle)

The nozzle is constructed so that the mist is directed upwards onto the opposite dispersion plate

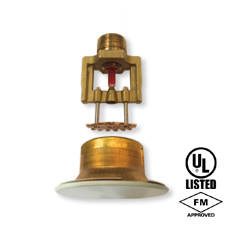

4. HD Fire sprinkler types

HD fire sprinklers are small, thermosensitive, glass-bulb water spray sprinklers available in several different models, finishes and temperature ratings to meet design requirements. These sprinklers come in brass construction with chrome coating, natural brass finish or custom colour finish. HD sprinklers can also be used as open sprinklers (glass bulb removed). There are sprinkler models suitable for specific requirements and hazards. HD also provides various sprinkler system accessories and products like HD-Flex sprinkler flexible drops, test and drain valves, sprinkler system check valves, etc. HD sprinklers are UL Listed and FM Approved. Not all models and configurations may carry all approvals. Please refer to product catalogues for approval information, technical specifications and ordering information.

Pendent Sprinklers

Upright Sprinklers

Horizontal Sidewall Sprinklers

HSW – Extended Coverage,

Quick Response Sprinklers

Vertical Sidewall Sprinklers

Concealed Sprinklers

Conventional Sprinklers

Recessed Sprinklers

Pendent, Upright, Recessed K-8 Sprinklers

Horizontal Sidewall K-8

Sprinklers

Test and Drain Valves

Sprinkler Guards

Pressure Relief Valves

Foam Water Sprinklers

Sprinkler Cabinet

Zone Control Manifold Assembly

Related projects

.png)