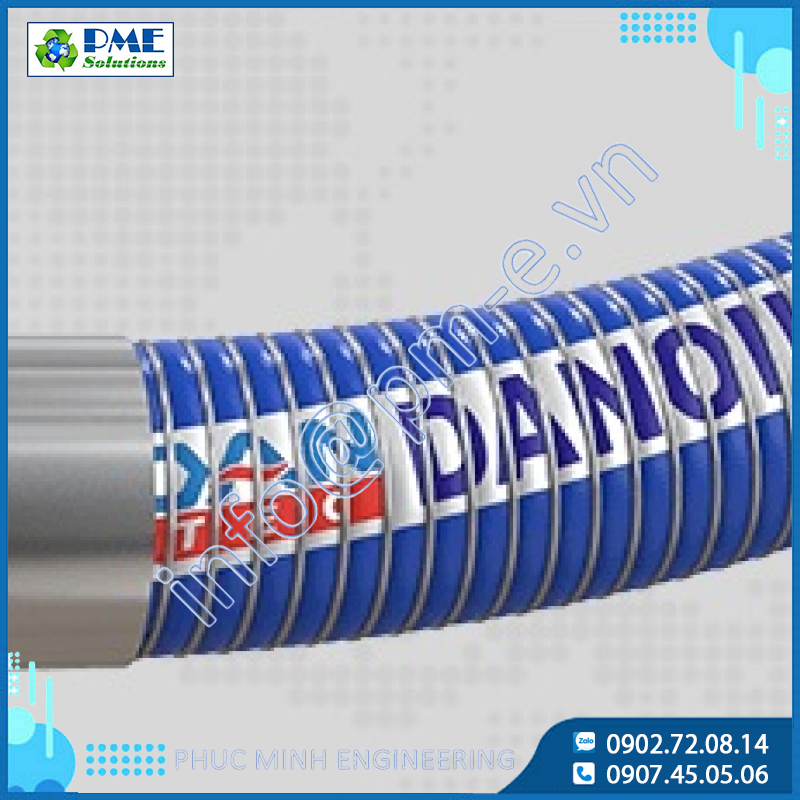

Composite hose

Price: Contact

Danoil® - Oil, Hydrocarbons, Aromatics, Solvents, Biofuels

Danoil family of Dantec composite hoses come in 3 grades; Danoil 3 (light hydrocarbons) Danoil 7 (Heavier hydrocarbons) Danoil 9 (Biofuel, Aromatics, Solvents).

Danoil® - Oil, Hydrocarbons, Aromatics, Solvents, Biofuels

Danoil family of Dantec composite hoses come in 3 grades; Danoil 3 (light hydrocarbons) Danoil 7 (Heavier hydrocarbons) Danoil 9 (Biofuel, Aromatics, Solvents).

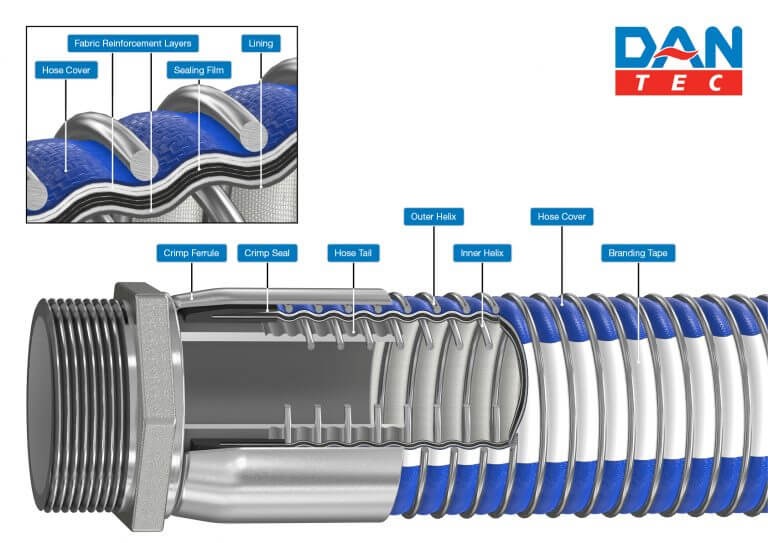

Both the Danoil 3 and Danoil 7 hoses, which are Dantec’s recommended hydrocarbon transfer hoses, are manufactured from multiple layers of polypropylene fabrics and films.

The inner helix is available in galvanised steel and aluminium. The outer wire is available in galvanised steel, and only in the case of the Danoil 3 is also available in aluminium.

Danoil 9 range is a polyamide (nylon) lined version of the Danoil 7; This hose is used for products with high aromatic content and biofuels. The inner helix is available in 316 stainless steel, galvanised steel and aluminium, with the outer wire available in 316 stainless steel and galvanised steel.

Danoil 3 range is a robust but light weight hose, which is only available as a 10.5 bar standard duty hose and is mainly used in gravity to low pressure applications, such as road tanker deliveries.

Danoil 7 and Danoil 9 range are both 14 bar, tough high strength transfer hose and they are available in both standard and heavy duty.

Standard duty version is used in rail car unloading and in plant transfers. Heavy duty is available for ship to shore and marine applications.

APPLICABLE STANDARDS:

- BS EN 13765: 2018

- HEAVY DUTY HOSES:

- INTERNATIONAL MARITIME ORGANISATION

- IBC CODE (FOR MARINE APPLICATIONS)

- UNITED STATES COASTGUARD REQUIREMENTS (FOR MARINE APPLICATIONS)

TECHNICAL DATA:

SIZES AVAILABLE:

STANDARD DUTY: 1” – 4” (25MM – 100MM)

HEAVY DUTY: 4” – 10” (100MM – 250MM)

TEMPERATURE RANGE: -30°C TO + 100°C

MAXIMUM WORKING PRESSURE:

- 7 BAR (DANOIL 3AA)

- 10.5 BAR (DANOIL 3AG, DANOIL 3GG)

- 14 BAR (DANOIL 7, DANOIL 9)*

VACUUM RANGE: 0.9 BAR

SAFETY FACTOR:

- 4:1 FOR STANDARD DUTY

- 5:1 FOR HEAVY DUTY

NOTE ALL WORKING PRESSURES CALCULATED ARE FOR TRANSFERS AT AMBIENT WORKING TEMPERATURE. ELEVATED TEMPERATURES MAY REDUCE WORKING PRESSURE OR SERVICE LIFE. CONTACT DANTEC FOR MORE INFORMATION.

SELECTION GUIDE:

INNER WIRE HELIX:

Stainless Steel: Premium choice, excellent chemical resistance, best mechanical strength. (Danoil 9SG, Danoil 9SS)

Galvanised Steel: Economical choice, good mechanical strength. (Danoil 3GG, Danoil 7GG, Danoil 9GG) Not to be used with Biofuels

Aluminium: Lightweight choices for hoses were weight is an issue (Danoil 3AA, Danoil 3AG, Danoil 7AG, Danoil 9AG)

OUTER WIRE HELIX:

Stainless Steel: Premium choice, excellent chemical resistance, best suited to weathering and external conditions (Danoil 9SS)

Galvanised Steel: Economical choice (Danoil 3AG, Danoil 3GG, Danoil 7GG Danoil 9AG, Danoil 9SG)

LINER:

Polypropylene: All hydrocarbon products (D3AA, D3AG, D3GG, D7AG, D7GG)

Polyamide: Excellent resistance for high aromatic solvents, MTBE, and biofuel (D9AG, D9GG, D9SG, D9SS)

DATA SHEETS

Danoil 3AA Composite Hose

BS EN 13765:2018 Type 1

| Bore Diameter | Max. Working Pressure | Bend Radius | Weight | |||

| INS | MM | BARS | PSI | INS | MM | KG/M |

| 3 | 75 | 7 | 100 | 8.0 | 205 | 1.5 |

| 4 | 100 | 7 | 100 | 10.5 | 265 | 1.9 |

CONSTRUCTION:

1. Inner Wire Helix: Aluminium Wire

2. Lining: Polypropylene

3. Sealing Film: Polypropylene

4. Reinforcements: Polypropylene

5. Cover: PVC Coated Polyester Cloth

6. Outer Wire Helix: Aluminium Wire

SAFETY FACTOR:

4:1

MAX VACUUM:

0.9 BAR

TEMPERATURE RANGE:

-30ºC to +100ºC

N.B. It is important to advise Dantec of the full working parameters when ordering Composite Hoses (medium, working temperature and working pressure). Working pressure rating stated above is based on transferring product at ambient temperatures (21°C/70°F). Elevated temperatures and end fitting ratings can severely reduce the working pressure of a hose assembly. Please consult Dantec technical sales with your requirements.

Danoil 3AG Composite Hose

BS EN 13765:2018 Type 2

Meets class 1 for aviation fuels

| Bore Diameter | Max. Working Pressure | Bend Radius | Weight | |||

| INS | MM | BARS | PSI | INS | MM | KG/M |

| 2.5 | 65 | 10 | 150 | 7.0 | 180 | 1.6 |

| 3 | 75 | 10 | 150 | 8.0 | 205 | 1.7 |

| 4 | 100 | 10 | 150 | 10.5 | 265 | 2.4 |

CONSTRUCTION:

1. Inner Wire Helix: Aluminium Wire

2. Lining: Polypropylene

3. Sealing Film: Polypropylene

4. Reinforcements: Polypropylene

5. Cover: PVC Coated Polyester Cloth

6. Outer Wire Helix: Galvanised Mild Steel High Tensile Strength Wire

SAFETY FACTOR:

4:1

MAX VACUUM:

0.9 BAR

TEMPERATURE RANGE:

-30°C to +100°C

N.B. It is important to advise Dantec of the full working parameters when ordering Composite Hoses (medium, working temperature and working pressure). Working pressure rating stated above is based on transferring product at ambient temperatures (21°C/70°F). Elevated temperatures and end fitting ratings can severely reduce the working pressure of a hose assembly. Please consult Dantec technical sales with your requirements.

Danoil 3GG Composite Hose

BS EN 13765:2018 Type 2

| Bore Diameter | Max. Working Pressure | Bend Radius | Weight | |||

| INS | MM | BARS | PSI | INS | MM | KG/M |

| 1 | 25 | 10 | 150 | 4.0 | 100 | 0.8 |

| 1.5 | 38 | 10 | 150 | 5.0 | 125 | 1.1 |

| 2 | 50 | 10 | 150 | 6.0 | 150 | 1.6 |

| 2.5 | 65 | 10 | 150 | 7.0 | 180 | 2.1 |

| 3 | 75 | 10 | 150 | 8.0 | 205 | 2.5 |

| 4 | 100 | 10 | 150 | 10.5 | 265 | 3.6 |

CONSTRUCTION:

1. Inner Wire Helix: Galvanised Mild Steel High Tensile Strength Wire

2. Lining: Polypropylene

3. Sealing Film: Polypropylene

4. Reinforcements: Polypropylene

5. Cover: PVC Coated Polyester Cloth

6. Outer Wire Helix: Galvanised Mild Steel High Tensile Strength Wire

SAFETY FACTOR:

4:1

MAX VACUUM:

0.9 BAR

TEMPERATURE RANGE:

-30°C to +100°C

N.B. It is important to advise Dantec of the full working parameters when ordering Composite Hoses (medium, working temperature and working pressure). Working pressure rating stated above is based on transferring product at ambient temperatures (21°C/70°F). Elevated temperatures and end fitting ratings can severely reduce the working pressure of a hose assembly. Please consult Dantec technical sales with your requirements.

Danoil 7AG Composite Hose

BS EN 13765:2018 Type 3

| Bore Diameter | Max. Working Pressure | Bend Radius | Weight | |||

| INS | MM | BARS | PSI | INS | MM | KG/M |

| 1.5 | 38 | 14 | 200 | 5.5 | 140 | 1.1 |

| 2 | 50 | 14 | 200 | 7.0 | 180 | 1.75 |

| 2.5 | 65 | 14 | 200 | 8.0 | 205 | 2.1 |

| 3 | 75 | 14 | 200 | 11.0 | 280 | 2.4 |

| 4 | 100 | 14 | 200 | 15.5 | 395 | 3.9 |

CONSTRUCTION:

1. Inner Wire Helix: Aluminium

2. Lining: Polypropylene

3. Sealing Film: Polypropylene

4. Reinforcements: Polypropylene

5. Cover: PVC Coated Polyester Cloth

6. Outer Wire Helix: Galvanised Mild Steel High Tensile Strength Wire

SAFETY FACTOR:

4:1

MAX VACUUM:

0.9 BAR

TEMPERATURE RANGE:

-30°C to +100°C

N.B. It is important to advise Dantec of the full working parameters when ordering Composite Hoses (medium, working temperature and working pressure). Working pressure rating stated above is based on transferring product at ambient temperatures (21°C/70°F). Elevated temperatures and end fitting ratings can severely reduce the working pressure of a hose assembly. Please consult Dantec technical sales with your requirements.

Danoil 7GG Composite Hose

BS EN 13765:2018 Type 3

| Bore Diameter | Max. Working Pressure | Bend Radius | Weight | |||

| INS | MM | BARS | PSI | INS | MM | KG/M |

| 1 | 25 | 14 | 200 | 4.0 | 100 | 0.8 |

| 1.5 | 38 | 14 | 200 | 5.5 | 140 | 1.2 |

| 2 | 50 | 14 | 200 | 7.0 | 180 | 1.9 |

| 2.5 | 65 | 14 | 200 | 8.0 | 205 | 2.5 |

| 3 | 75 | 14 | 200 | 11.0 | 280 | 3.0 |

| 4 | 100 | 14 | 200 | 15.5 | 395 | 5.2 |

CONSTRUCTION:

1. Inner Wire Helix: Galvanised Mild Steel High Tensile Strength Wire

2. Lining: Polypropylene

3. Sealing Film: Polypropylene/Polyester

4. Reinforcements: Polypropylene

5. Cover: PVC Coated Polyester Cloth

6. Outer Wire Helix: Galvanised Mild Steel High Tensile Strength Wire

SAFETY FACTOR:

4:1

MAX VACUUM:

0.9 BAR

TEMPERATURE RANGE:

-30°C to +100°C

N.B. It is important to advise Dantec of the full working parameters when ordering Composite Hoses (medium, working temperature and working pressure). Working pressure rating stated above is based on transferring product at ambient temperatures (21°C/70°F). Elevated temperatures and end fitting ratings can severely reduce the working pressure of a hose assembly. Please consult Dantec technical sales with your requirements.

Danoil 7GG HD Composite Hose

BS EN 13765:2018 Type 3 (4"-8")

BS EN 13765: 2018 Type 2 (10”)

Meets the requirement of the US Coastguard & IMO Code

| Bore Diameter | Max. Working Pressure | Bend Radius | Weight | |||

| INS | MM | BARS | PSI | INS | MM | KG/M |

| 4 | 100 | 14 | 200 | 16 | 405 | 6.4 |

| 6 | 150 | 14 | 200 | 20 | 510 | 10.7 |

| 8 | 200 | 14 | 200 | 30 | 760 | 15.0 |

| 10 | 250 | 14 | 200 | 36 | 915 | 20.5 |

CONSTRUCTION:

1. Inner Wire Helix: Galvanised Mild Steel High Tensile Strength Wire

2. Lining: Polypropylene

3. Sealing Film: Polypropylene/Polyester

4. Reinforcements: Polypropylene

5. Cover: PVC Coated Polyester Cloth

6. Outer Wire Helix: Galvanised Mild Steel High Tensile Strength Wire

SAFETY FACTOR:

5:1

MAX VACUUM:

0.9 BAR

TEMPERATURE RANGE:

-30°C to +100°C

N.B. It is important to advise Dantec of the full working parameters when ordering Composite Hoses (medium, working temperature and working pressure). Working pressure rating stated above is based on transferring product at ambient temperatures (21°C/70°F). Elevated temperatures and end fitting ratings can severely reduce the working pressure of a hose assembly. Please consult Dantec technical sales with your requirements.

Danoil 9AG Composite Hose

BS EN 13765:2018 Type 3

| Bore Diameter | Max. Working Pressure | Bend Radius | Weight | |||

| INS | MM | BARS | PSI | INS | MM | KG/M |

| 2 | 50 | 14 | 200 | 7.0 | 180 | 1.75 |

| 2.5 | 65 | 14 | 200 | 8.0 | 205 | 2.1 |

| 3 | 75 | 14 | 200 | 11.0 | 280 | 2.4 |

| 4 | 100 | 14 | 200 | 15.5 | 395 | 3.9 |

CONSTRUCTION:

1. Inner Wire Helix: Aluminium

2. Lining: Polyamide

3. Sealing Film: Polypropylene/Polyamide

4. Reinforcements: Polypropylene

5. Cover: PVC Coated Polyester Cloth

6. Outer Wire Helix: Galvanised Mild Steel High Tensile Strength Wire

SAFETY FACTOR:

4:1

MAX VACUUM:

0.9 BAR

TEMPERATURE RANGE:

-30°C to +100°C

N.B. It is important to advise Dantec of the full working parameters when ordering Composite Hoses (medium, working temperature and working pressure). Working pressure rating stated above is based on transferring product at ambient temperatures (21°C/70°F). Elevated temperatures and end fitting ratings can severely reduce the working pressure of a hose assembly. Please consult Dantec technical sales with your requirements.

Danoil 9GG Composite Hose

BS EN 13765:2018 Type 3

| Bore Diameter | Max. Working Pressure | Bend Radius | Weight | |||

| INS | MM | BARS | PSI | INS | MM | KG/M |

| 1 | 25 | 14 | 200 | 4.0 | 100 | 0.8 |

| 1.5 | 38 | 14 | 200 | 5.5 | 140 | 1.2 |

| 2 | 50 | 14 | 200 | 7.0 | 180 | 1.9 |

| 2.5 | 65 | 14 | 200 | 8.0 | 205 | 2.5 |

| 3 | 75 | 14 | 200 | 11.0 | 280 | 3.0 |

| 4 | 100 | 14 | 200 | 15.5 | 395 | 5.2 |

CONSTRUCTION:

1. Inner Wire Helix: Galvanised Mild Steel High Tensile Strength Wire

2. Lining: Polyamide

3. Sealing Film: Polypropylene/Polyester

4. Reinforcements: Polypropylene

5. Cover: PVC Coated Polyester Cloth

6. Outer Wire Helix: Galvanised Mild Steel High Tensile Strength Wire

SAFETY FACTOR:

4:1

MAX VACUUM:

0.9 BAR

TEMPERATURE RANGE:

-30°C to +100°C

N.B. It is important to advise Dantec of the full working parameters when ordering Composite Hoses (medium, working temperature and working pressure). Working pressure rating stated above is based on transferring product at ambient temperatures (21°C/70°F). Elevated temperatures and end fitting ratings can severely reduce the working pressure of a hose assembly. Please consult Dantec technical sales with your requirements.

Danoil 9GG HD Composite Hose

BS EN 13765: 2018 Type 3 (4”-10”)

Meets the requirement of the US Coastguard & IMO Code

| Bore Diameter | Max. Working Pressure | Bend Radius | Weight | |||

| INS | MM | BARS | PSI | INS | MM | KG/M |

| 4 | 100 | 14 | 200 | 16 | 405 | 6.4 |

| 6 | 150 | 14 | 200 | 20 | 510 | 10.7 |

| 8 | 200 | 14 | 200 | 30 | 760 | 15.0 |

| 10 | 250 | 14 | 200 | 36 | 915 | 20.5 |

CONSTRUCTION:

1. Inner Wire Helix: Galvanised Mild Steel High Tensile Strength Wire

2. Lining: Polyamide

3. Sealing Film: Polyamide/Polypropylene

4. Reinforcements: Polypropylene

5. Cover: PVC Coated Polyester Cloth

6. Outer Wire Helix: Galvanised Mild Steel High Tensile Strength Wire

SAFETY FACTOR:

5:1

MAX VACUUM:

0.9 BAR

TEMPERATURE RANGE:

-30°C to +100°C

N.B. It is important to advise Dantec of the full working parameters when ordering Composite Hoses (medium, working temperature and working pressure). Working pressure rating stated above is based on transferring product at ambient temperatures (21°C/70°F). Elevated temperatures and end fitting ratings can severely reduce the working pressure of a hose assembly. Please consult Dantec technical sales with your requirements.

Danoil 9SG Composite Hose

BS EN 13765:2018 Type 3

| Bore Diameter | Max. Working Pressure | Bend Radius | Weight | |||

| INS | MM | BARS | PSI | INS | MM | KG/M |

| 1 | 25 | 14 | 200 | 4.0 | 100 | 0.8 |

| 1.5 | 38 | 14 | 200 | 5.5 | 140 | 1.2 |

| 2 | 50 | 14 | 200 | 7.0 | 180 | 1.9 |

| 2.5 | 65 | 14 | 200 | 8.0 | 205 | 2.5 |

| 3 | 75 | 14 | 200 | 11.0 | 280 | 3.0 |

| 4 | 100 | 14 | 200 | 15.5 | 395 | 5.2 |

CONSTRUCTION:

1. Inner Wire Helix: 316 Stainless Steel High Tensile Strength Wire

2. Lining: Polyamide

3. Sealing Film: Polypropylene/Polyamide

4. Reinforcements: Polypropylene

5. Cover: PVC Coated Polyester Cloth

6. Outer Wire Helix: Galvanised Mild Steel High Tensile Strength Wire

SAFETY FACTOR:

4:1

MAX VACUUM:

0.9 BAR

TEMPERATURE RANGE:

-30°C to +100°C

N.B. It is important to advise Dantec of the full working parameters when ordering Composite Hoses (medium, working temperature and working pressure). Working pressure rating stated above is based on transferring product at ambient temperatures (21°C/70°F). Elevated temperatures and end fitting ratings can severely reduce the working pressure of a hose assembly. Please consult Dantec technical sales with your requirements.

1. Introduction to DANTEC Composite Hose

DANTEC composite hose is a high-quality industrial hose manufactured by Dantec Ltd – a leading UK brand in specialized hoses. With advanced production technology, Dantec hoses meet the stringent standards of the oil and gas, chemical, food, and maritime industries.

2. Outstanding Features of DANTEC Composite Hose

-

Optimal Corrosion Resistance: With a high-quality chemical-resistant lining, Dantec hoses can withstand harsh chemical environments, acids, alkalis, and organic solvents.

-

Lightweight & High Durability: Thanks to its special composite structure, Dantec hoses are lighter than metal hoses while ensuring superior durability.

-

High Flexibility: Dantec hoses are easy to bend, making installation quick and convenient in various industrial applications.

-

High Temperature & Pressure Resistance: Designed to operate under extreme temperature and pressure conditions, suitable for multiple working environments.

-

Compliance with International Standards: Dantec hoses are certified with ISO 9001, EN 13765, EN 13766, and many other safety standards.

3. Applications of DANTEC Composite Hose

Dantec hoses are widely used in industries such as:

-

Oil & Gas: Transporting fuel, crude oil, LPG, LNG.

-

Chemical: Conveying liquid chemicals, acids, solvents.

-

Food & Pharmaceuticals: Used in safe transport of liquid food and pharmaceuticals.

-

Maritime: Used on oil tankers, ports.

4. Why Buy DANTEC Composite Hose from Phuc Minh Engineering?

Phuc Minh Engineering (PME) is the official distributor of Dantec composite hoses in Vietnam, committed to providing genuine products, competitive prices, and professional after-sales services:

-

Stock availability, fast nationwide delivery.

-

Official warranty, complete CO, CQ documents.

-

24/7 technical support, in-depth consultation for each project.

5. Contact Us for Genuine Dantec Hose Quotation

📌 Phuc Minh Engineering (PME)

☎ Hotline: 0902720814 - 0907450506

📧 Email: info@pm-e.vn - sales@pm-e.vn

🌐 Website: www.pm-e.vn

👉 Contact us now for a free consultation and quotation on genuine Dantec composite hoses!

Related projects

.png)