Compression Packings

Price: Contact

HYBRID

Hybrid packings are a combination of available yarns that would be suitable for applications where due to service requirements a special mix of yarns is required.

This would include applications such as reciprocating pumps. Agitators, Outlet devices and difficult applications where high stresses and pressures are involved.

Depending on the yarns used and configurations they can also be used in what would be classed as standard applications.

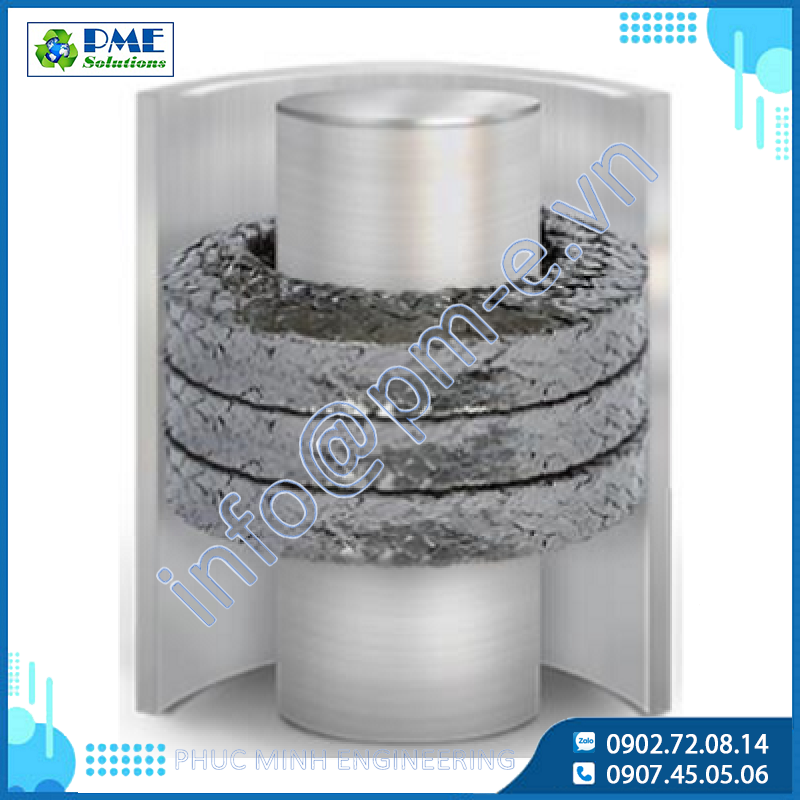

K55CCC

Expanded PTFE graphite reinforced with high strength Carbon yarns and Carbon corners. Blocked out with fine graphite.

One of the most versatile pump packings for all slurry applications as the unique structure of the packing ensures low abrasion, and reduces shaft and sleeve wear.

Offers a high degree of abrasion resistance in slurry applications and can be used in virtually all media including strong acids and alkalis.

Suitable for use as a general and specialist packing in highly caustic liquor and Bauxite pumps.

K4313

A hybrid packing that combines the properties of Aramid and PTFE resulting in an excellent dynamic packing for rotary and reciprocating duties.

The result is a packing with high resistance to extrusion that is best suited to high operating pressures and PTFE compatible speeds.

The strong aramid corner posts resist extrusion from the stuffing box while ensuring that unwanted particles are excluded. This reduces the detrimental effects of abrasive and viscous media which shorten packing life and reduce performance.

283R

Constructed with a pre-braided centre of carbon yarn pre twisted with graphite exfoliant. Around this centre is a braided single layer of Inconel wire, which aids in extraction of the whole sealing ring in one piece. The centre core is over braided with high temperature Polyimidazole textiles.

The outer braid maintains integrity during continuous use at 700°F (371°C) and at short-term excursions up to 800°F (427°C).

It serves to provide substantial and continuous strength against the shaft. This is an advantage over other sealing materials such as PTFE types that degrade and harden at the operational temperatures resulting in helical scoring of the shaft during tube run-out. The outer structure protection of the inner, pure core is the mechanical and thermal braid requirement for long term soot blower sealing success.

2017

High performance, engineering polymer based monofilament pre twisted with 99.6% carbon yarn, asymmetric matrix, inter braided.

Monofilament polymer portion exhibits very high tensile strength which resists “picking” and fraying.

Carbon yarn portion exhibits significant heat dissipation.

Pre twisting of both yields all characteristics present through entire matrix. Both textiles much “easier” on shafts than all other synthetics.

The “Tough Stuff”. Super heat conductivity. Highly suited for harsh mining environments like bauxite, gold, copper, coal, phosphate, etc. Pulp and paper applications include Liquors and Paper stock.

7413

Constructed from seven (7) different textiles, utilizing core to outside surface design technology. A super-dense pre-braided core is enmeshed allowing for easy extraction at the end of 7413’s operating life. Several blocking stages ensure zero porosity.

It resists “bunching” or “snaking” which requires both high tensile strength as well as a high compressive strength final product.

Heat conductivity is continual while contact friction is minimized. Maintenance personnel accomplish removal in complete rings. The best product on the market today for Outlet Devices, Screw Conveyors and Agitators.

Related projects

.png)