About Didtek Valve

Established in 1985, Didtek Valve is a preferred supplier of industrial valves for major Chinese manufacturers.

Through 30 years’ development, Didtek valve has been recognized as a valve manufacturer with superior quality and capability of meeting all kinds of technical requirements of customers. It can produce customized products for a variety of intentions, being highly popular among customers.

The factory of Didtek valve is located in Oubei (Zhejiang, China), covering an area of 25,000 square meters, of which square meter is for office work whereas 24,000 square meters is for production (including the assembly area, testing area and warehouse area). Moreover, the factory is only 9 miles to Yong Qiang Airport, greatly facilitating for the visitor of our international customers and partners.

Boasting of excellent technical strength, design and experience in Gate, Ball, Butterfly and Bellow valves manufacturing, the company has a quality management system as required by ISO9001-2008 and has obtained the Pressure Equipment Directive 97/23 CE (PED).

The certifications of Didtek valve include ISO9001:2008, PED directive Mod H, API 6D, CU TR 010/032

Didtek Valve have been working to find reliable sales agents or distributors.

Related News

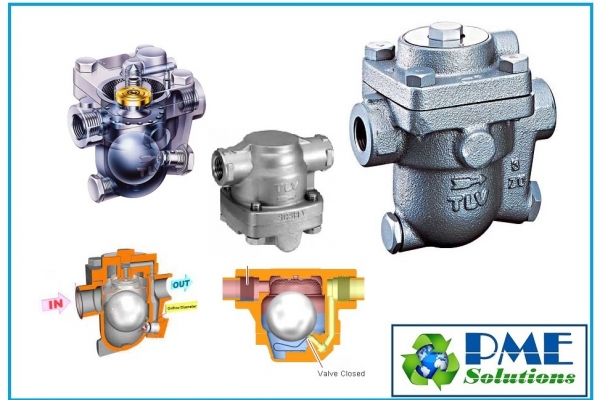

VINVAL Float Steam Trap – The Optimal Solution for Industrial Steam Systems

07/05/2025

VINVAL Float Steam Trap – The Optimal Solution for Industrial Steam Systems Welcome to Phuc Minh Industrial Valves – the official importer and distributor of VINVAL Float Steam Traps in Vietnam. We are proud to present the VINVAL product line, a premium solution for effectively removing condensate, minimizing steam loss, and maximizing efficiency in industrial steam systems. Why Choose the VINVAL Float Steam Trap?

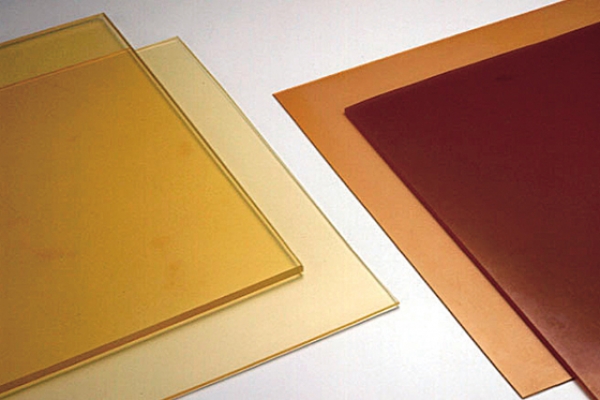

Polyurethane rubberUrethane Rubber Sheet (Ti-Prene Sheet)

23/04/2025

Polyurethane rubberUrethane Rubber Sheet (Ti-Prene Sheet) Function ・ Mechanical Strength ・ Impact Resilience ・ Abrasion Resistance ・ Ozone Resistance ・ Oil Resistance About Urethane Rubber Sheet (Ti-Prene Sheet) Rubber-like elastic bodies obtained by the reaction of polyester or polyether with isocyanate are collectively called urethane rubber. Ti-Prene® is a trademark of our urethane rubber. Features Mechanical Strength: Due to its chemical structure, it has a strong secondary bond between molecules, so it has the highest strength among elastic bodies, and because of its high modulus, it is to be less deformed and can withstand heavy loads even with small objects. Due to its high hardness and high elongation, it is to be less susceptible to damage due to impact. Abrasion Resistance: It has more than 10 times more abrasion resistance than natural rubber. It is to be superior to metal in some conditions of use. Oil Resistance: It has excellent resistance to most oils, including petroleum-based oils. Especially excellent for mineral oil (only for use at room temperature). Heat Resistance: The using limit temperature is 70 ° C. Avoid using continuously at 70 ° C or more. Cold Resistance: It has rubber elasticity and mechanical strength even at -25 ° C or less. Water Resistance: Please avoid using it in a hot and humid environment because it has the property of being easily hydrolyzed. Ozone Resistance: It is hardly affected by ozone because it does not contain unsaturated parts in its molecular structure. Weather Resistance: Please be noted that when used outdoors for a long period of time, the effects of water, humidity, light, etc. may cause deterioration of physical properties and discoloration.

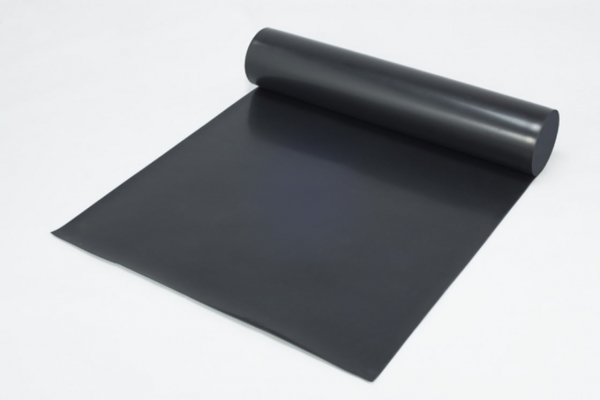

EPT Sheet (Ethylene-propylene terpolymer rubber)

23/04/2025

EPT Sheet (Ethylene-propylene terpolymer rubber) Features ・Excels in weather resistance. ・Excels in ozone resistance. ・Excels in cold resistance. ・Excels in heat resistance. Applications ・Seal material for window frame. ・Bulletin Board.

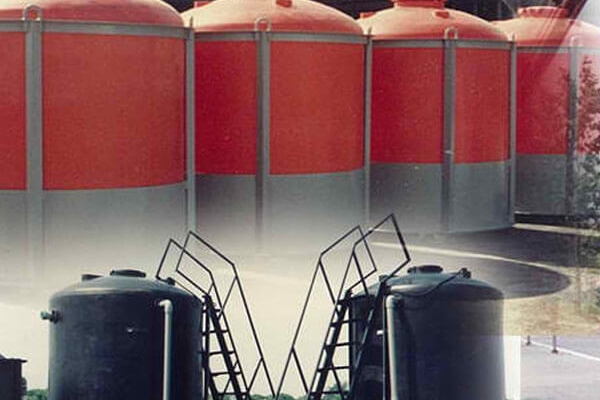

Chemical & Water Tanks

23/04/2025

Chemical & Water Tanks All tanks supplied by our supplier are either rotomoulded or blow moulded. PE rotomoulded or blow moulded tanks are one piece seamless tanks produced from polyethylene using rotational moulding or blow moulding process which offer superior quality as they are corrosion resistant, flexible and will not break or shatter under normal expansion and contraction. PE tanks are competitively priced and suitable as storage and transportation tanks for a wide range of chemicals and can be used by water and wastewater industries and any industry that require storage or movement of chemicals. Polyethylene resins used to manufacture PE tanks is an ethylene octane copolymer specifically designed for applications requiring excellent environmental stress crack resistance and impact strength combined with low warpage. It is fully head and UV stabilized resulting in good colour retention and long life expectancy. The resins comply with U.S. FDA 21 CFR 177.1520©3.1a

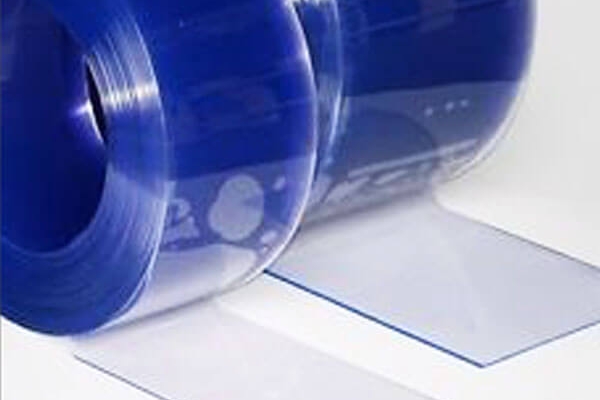

PVC Curtains & Doors

23/04/2025

PVC Curtains & Doors PE Rotomoulded Tanks PVS Curtain strips for curtain doors from 2mm to 5mm PVC clear rools S.S Accessories for installation of curtain strips Stainless steel

.png)