Comprehensive Overview of Oil and Gas Valves: Optimal Solutions for the Oil and Gas Industry

Introduction to Oil and Gas Valves

Oil and gas valves are crucial components in the oil and gas industry, playing a vital role in controlling the flow of oil, gas, and other fluids during extraction, transportation, and processing. Choosing and maintaining the right valves not only enhances operational efficiency but also ensures the safety of the entire system.

.jpg)

Common Types of Oil and Gas Valves

Gate Valves

Gate valves are widely used to control the opening and closing of flow in oil and gas systems. They provide a tight seal, ideal for applications requiring unobstructed flow when fully open. However, gate valves are not suitable for flow regulation.

Globe Valves

Globe valves are suitable for regulating flow. They provide excellent shutoff capabilities and can be used in both on/off and flow regulation applications. Their design allows for high pressure control, making them ideal for systems requiring precise management.

Ball Valves

Ball valves offer exceptional shutoff capabilities and are easy to operate. They are suitable for both on/off control and flow regulation, making them widely used in oil and gas systems due to their durability and high performance.

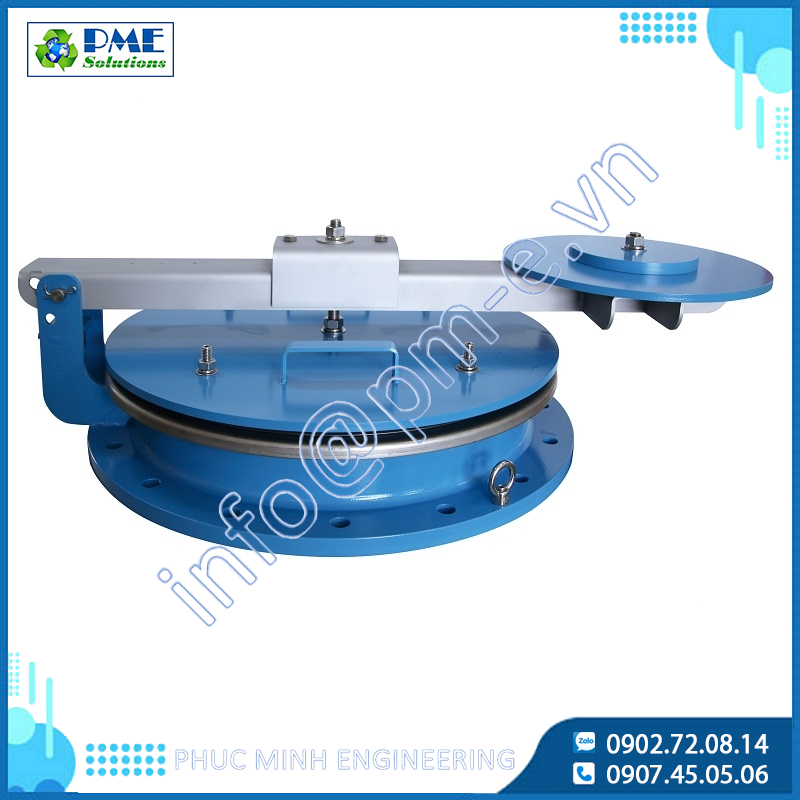

Butterfly Valves

Butterfly valves are lightweight, cost-effective, and can handle large volumes of flow. They are often used in applications with limited installation space and require efficient flow control.

Check Valves

Check valves prevent backflow, protecting systems and equipment from damage. They allow flow in one direction and automatically close to prevent reverse flow.

Plug Valves

Plug valves are suitable for on/off control and flow regulation. They offer quick and simple flow control solutions, especially effective in high-pressure and high-temperature environments.

.jpg)

Key Features of Oil and Gas Valves

High Durability

Oil and gas valves are made from materials that withstand harsh conditions, such as stainless steel, carbon steel, and special alloys. This ensures that the valves can endure high pressure, extreme temperatures, and corrosive environments.

Safety and Compliance

Safety is paramount in the oil and gas industry. Valves must comply with stringent safety standards to prevent leaks and accidents. Certifications from reputable organizations ensure that the valves meet rigorous safety and quality requirements.

High Efficiency

Oil and gas valves are designed to operate efficiently, minimizing pressure loss and ensuring stable flow. Features like low torque operation and quick response times help maintain optimal performance.

.jpg)

Practical Applications of Oil and Gas Valves

Upstream

In upstream operations, oil and gas valves are used in drilling rigs and extraction systems. Gate valves and ball valves are commonly used to control the flow from wells.

Midstream

In midstream operations, which include the transportation and storage of oil and gas, valves are used in pipelines, storage tanks, and pumping stations. Check valves and butterfly valves are essential for maintaining flow control and preventing backflow.

Downstream

In downstream operations, which involve refining and processing oil and gas, globe valves and plug valves are used to regulate flow and control pressure at various stages of processing. They ensure that the refining processes are safe and efficient.

Selection and Maintenance of Oil and Gas Valves

Selecting Oil and Gas Valves

When selecting oil and gas valves, consider the following factors:

- Operating Conditions: Pressure, temperature, and type of fluid.

- Valve Function: On/off control, flow regulation, or backflow prevention.

- Material Compatibility: Ensuring the valve material is suitable for the fluid and operating environment.

Valve Maintenance

Regular maintenance is crucial to ensure the efficient operation and longevity of oil and gas valves. Maintenance activities include:

- Periodic Inspections and Testing: Detect and address issues such as leaks, corrosion, and wear.

- Cleaning and Lubrication: Ensure smooth operation and prevent deposit buildup.

- Replacement of Parts: Timely replacement of seals, gaskets, and other components to prevent failures.

.jpg)

Conclusion

Oil and gas valves are essential for ensuring the safety and efficiency of oil and gas operations. Understanding the different types of valves, their features, and applications helps in selecting the right valve for specific needs. Regular maintenance ensures that the valves operate reliably, enhancing overall performance and safety.

If you are looking for a reliable industrial valve solution for the oil and gas industry, consider investing in high-quality products. Contact Phuc Minh Engineering to advise and choose the most suitable valves for your needs, ensuring optimal performance and safety in your operations.

>>>>See more: Overview of gate valves: Instructions for use and applications

PHUC MINH ENGINEERING COMPANY LIMITED

Address: 92/38 Street 12, Quarter 18, Binh Hung Hoa Ward, Binh Tan District, Ho Chi Minh City

Hotline: +842835352125

Email: info@pm-e.vn

Website: www.pm-e.vn

.png)