Difference between ball valve, gate valve and globe valve

As we all know, ball valve, gate valve & globe valve (ball valve, gate valve & check valve) are three types of valves commonly used in pipeline systems, they are all used for the same purpose. open/close or regulate the flow. So what is the difference between them? When do we use ball valve, gate valve or globe valve? In the following article, we would like to share some basic experiences to distinguish this type of valve.

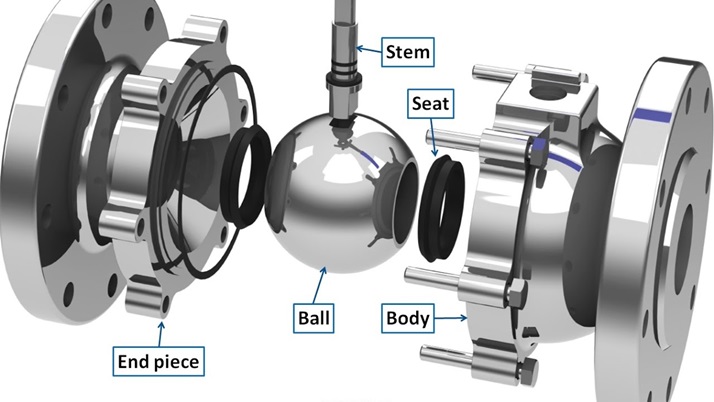

1. Ball valve

Ball valve, English name is Ball valve, is the most commonly used valve in pipeline systems with quick opening/closing ability, is considered as a valve with perfect service life & ability after long time use. The opening / closing mechanism of the ball valve is through a hollow ball inside the body, which is controlled through the shaft linked to the upper control arm. The control arm closes/opens at an angle of 90 degrees, when the control arm is perpendicular to the pipeline/valve body – it means the valve is in the closed position. And vice versa, when the control arm is parallel to the pipe – this means the valve is open. Depending on the size & working conditions, there are many options of materials, hand control styles, etc. for users to choose from.

Advantages & disadvantages of ball valve:

* Advantages:

- Ball valve has a simple structure, but very solid, easy to operate.

- Withstand high pressure, well adapted to a variety of harsh environments.

- Extremely suitable for opening/closing applications, especially fast-opening/closing applications.

* Defect:

- Due to the valve line used to open / close quickly, the frictional pressure between the ball body and the sealing gasket is very large. These parts are often damaged during use.

- Not suitable for dirty or thick media.

- Usually well used for the purpose of opening / closing, but the ability to regulate accuracy is low & medium.

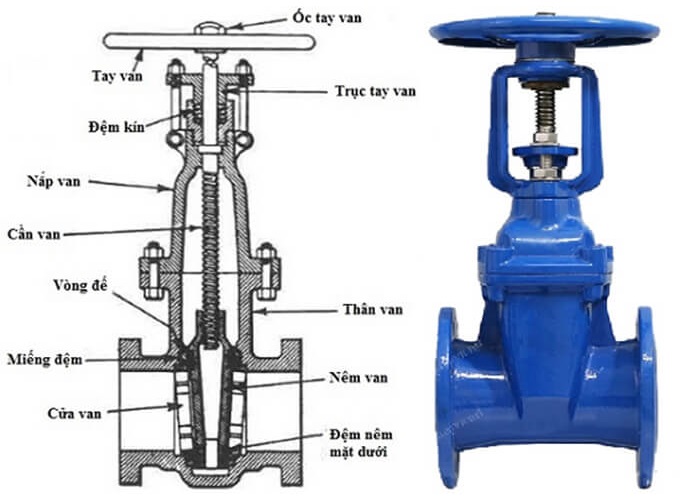

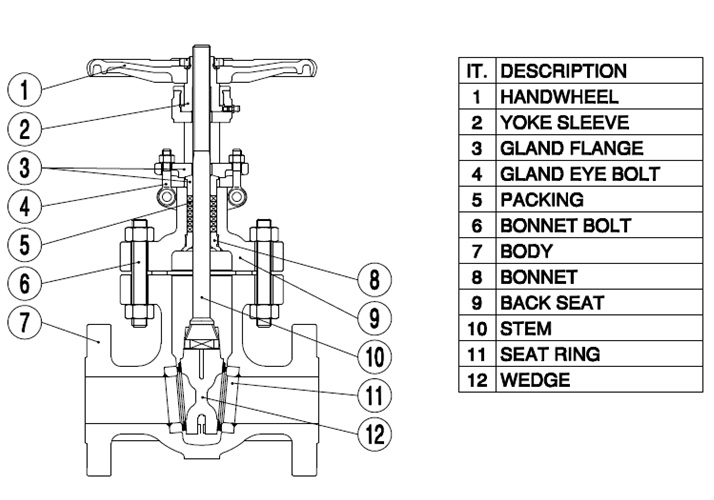

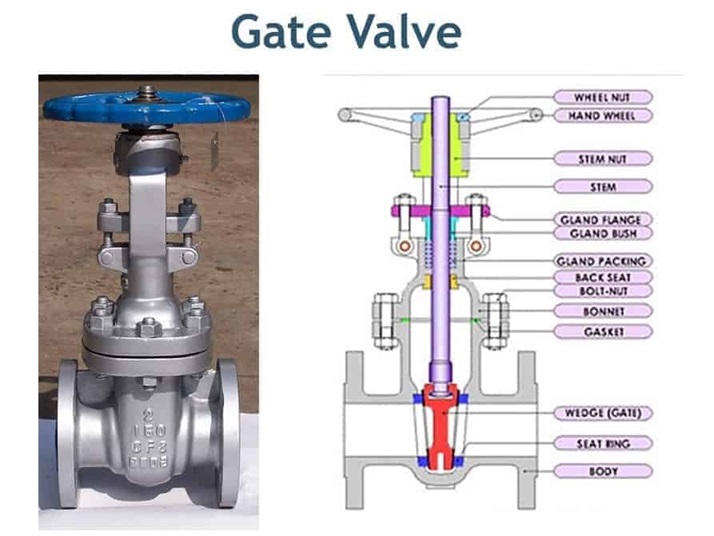

2. Gate valve

Gate valve (also known as gate valve), English name is Gate valve, they are called gate valve because of the opening/closing mechanism of this type of valve through the valve shaft to control the valve disc (also called gate valve). valve) moves up/down like a gate. When the valve disc is in the lowest position (closer to the valve seat), it means that the valve is closed - the flow does not circulate. And vice versa, when the valve is open, the position of the valve port is at the highest position. With the above operating mechanism, the gate valve is susceptible to corrosion and should only be used in the fully open or closed positions (because in the case of a partially open/closed valve, the valve disc will be shaken by the impact of the current. melt and easily lead to damage).

Pros & cons of gate valves:

* Advantages:

- Gate valve has high durability, less maintenance and maintenance.

- Globe valve has a flow & flow rate that does not change when passing through the valve, helping the system to operate stably.

- Operating the gate valve is relatively easy.

- Narrow body width, easy to install in any position.

* Defect:

- Because of the specificity in the operating mechanism, gate valves are rarely used for the purpose of regulating flow.

- The opening and closing stroke is slow, so it is not suitable for fast opening and closing positions.

- When the valve is not closed completely, noise will be generated.

- High maintenance and maintenance costs due to complex structure. Often users will skip the valve repair phase, but will replace the valve completely when damaged.

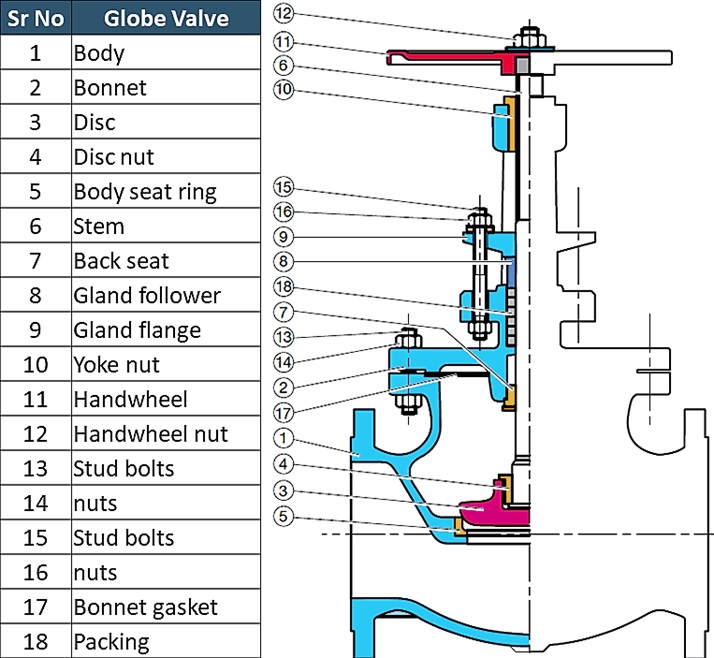

3. Globe valve.

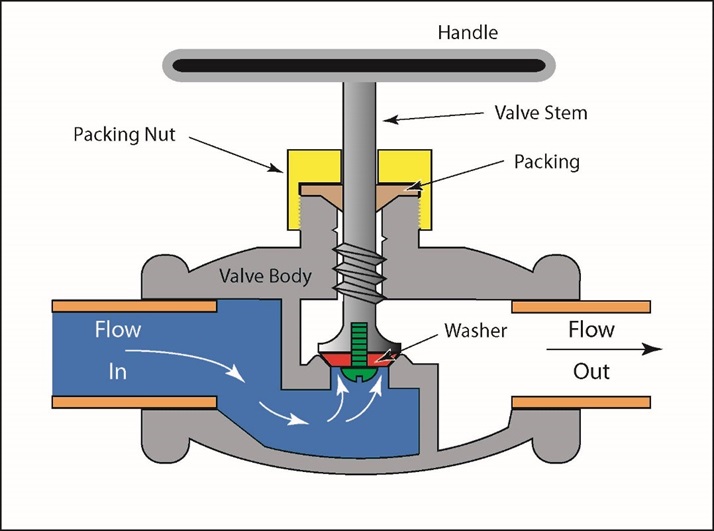

Globe valve (also known as saddle valve or fall valve), English name is Globe Valve, is a valve with a saddle-shaped (or fall-shaped) disc design, helping the flow to flow in a rectangular shape. Z should flow in a certain direction. The operating mechanism of the globe valve is similar to the gate valve, the valve disc is controlled through the valve shaft linked to the control arm. While ball valves & gate valves are only appreciated for opening/closing the circulating flow, globe valves are used in addition to opening/closing, and are also used in locations where flow regulation is often required (opening/closing is not open/closed). completely).

Pros & cons of globe valves:

* Advantages:

- Globe valve is easy to install & simple to operate.

- Globe valve has the ability to regulate the flow well, the ability to open / close easily & conveniently

- If operated regularly, the valve has high durability and the valve disc is less damaged and corroded

- Globe valve is controlled by a handwheel (hanwheel), so the pressure mechanism from the handwheel presses directly on the valve disc in the right direction, so in case the valve is completely closed, the possibility of fluid leakage is lower than other types of valves. .

- Globe valve has many designs, can be used in many applications, postures, easy to integrate with automatic controllers.

* Defect:

Globe valves are more expensive than other valves.

The pressure passing through the valve is reduced due to the diverted flow in the valve body.

Larger valves require a larger opening force than other valves.

- Weight & size of globe valve is usually larger than other valves of the same size.

- The upper surface of the valve seat and the lower surface of the valve disc are directly affected by the flow, so the flow condition in the valve creates air bubbles, causing cavitation in the valve seat (Seat). , when flowing in the opposite direction, it causes cavitation of the valve disc angle with the valve shaft.

The international standards applicable to valves today:

- API 6D - Specification for Pipeline and Piping Valves: Standard for valves of conveyance and technology pipelines.

- API 6FA - Specification for Fire Test for Valves: Standard for fire resistance testing for valves.

- API 598 - Valves Inspection and Testing: Standard for valve testing and inspection.

- API 607 - Fire Test for Quarter-turn Valves and Valves Equipped with Non-metallic Seats: Standard for fire testing of non-metallic internal valve seals.

- API 602 - Steel Gate, Globe, and Check Valves for Sizes NPS 4 (DN 100) and Smaller for Petroleum and Natural Gas Industries: Standard for gate, globe, and check valves for diameters less than or equal to 4 print.

- API 609 - Butterfly Valves (Double-flanged, Lug- and Wafer-type): Standard for butterfly valves with flange connection or lug/wafer-lug type.

- API 600 - Steel Gate Valves — Flange and Butt-welding Ends, Bolted Bonnet: Connection standard for gate valves (flange connection, butt-welded connection, bolt connection for valve cover).

.png)