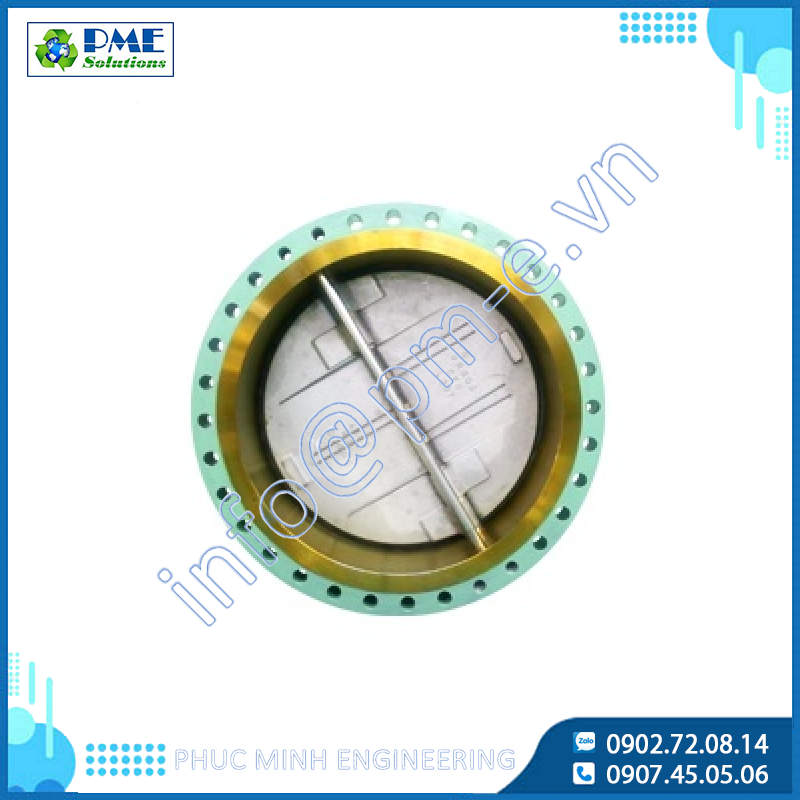

DK VALVE

PTFE-lined butterfly valve

Lining Materials

▪ PFA

PFA exhibits thermal characteristic like PTFE, being able to withstand super low to high temperature. It is also transparent and mechanically strong under high temperature. It is easily workable besides applicable with extrusion molding to the same degree as general thermoset plastic. It is used where purity is important, such a semiconductor wafer baskets, piping couplings and non-corrosive linings. PFA has better mechanical strength at high temperature than FEP, and excellent moldability for easy processing by extrusion, compression, blow, transfer and injection molding methods. Due to high bonding strength of carbon, fluorine and oxygen atoms, PFA demonstrates nearly the same outstanding capabilities as PTFE.

▪ FEP

FEP is a copolymer of tetra-fluoro-ethylene and hexa-fluoro-propylene. FEP consists of carbon anf fluorine atoms, as PTFE does, and has a molecular structure in which one of fluorine atoms bonded to carbon atoms, as PTFE does, and has a molecular structure in which one of fluorine atoms bonded to carbon atoms. FEP has a lower melt viscosity than PTFE and can be processed like other molten thermoplastic resins by extrusion, transfer, injection and compression molding. Because the bonding energy between its carbon and fluorine atoms is so high, and because the carbon chain is completely surrounded by fluorine atoms, FEP fluorocarbon polymer retains excellent thermal, electrical and chemical stability.

▪ PTFE

The fluorine atoms completely cover the carbon chain backbone and protect the carbon-carbon bond from attack. The fluorine atoms are also responsible for low surface energy and exceptional friction characteristics of PTFE. Because of very high melt viscosity, PTFE does not flow above its melting point. It requires special ploymer processing like past extrusion, compression molding and sintering. Among all the fluoro-plastic products, PTFE offers the highest heat resistances. It is not corroded and has good electrical insulation and dielectric characteristics. Moreover, it has a unique non-stick property and the lowest coefficient of friction among solids. It is the most widely used fluoro-plastic.

Standard Specifications

DESIGN

▪ API 609 Cat.A

▪ ISO 5752 Sr.20

▪ MSS SP 67

FACE-TO-FACE

▪ API 609 Cat. A

▪ Wafer and Lugged

FLANGE STANDARD

▪ ASME B 16.5

▪ BS 4504 / EN 1092-1

▪ JIS B2220

▪ Others on request

PRESSURE RATING

▪ ASME B 16.34

▪ Class 150

NOMINAL DIAMETER

▪ 2” to 24”

▪ DN 50 to 600

TESTING

▪ API 598

▪ High voltage pin hole test

Applicable Materials

| Cast Iron | A126 CL.B |

| Ductile Iron | A395 Gr.60-40-18, A536 Gr.65-45-12 |

| Austenitic Stainless Steel | A351 CF8 / CF8M / CF3 / CF3M |

| Duplex Stainless Steel | A890 4A / 5A / 6A, A995 4A / 5A / 6A |

| Special Alloy | Inconel® 625(UNS N06625), 254SMO®(UNS S31254) Monel® K400 / 500 (UNS N04400 / N05500) |

Related projects

.png)