Technical Analysis of All Types of Check Valves

Industrial valves are a vital component in modern manufacturing processes and industrial systems. This article will provide an overview of the uses and benefits of industrial valves in various industries.

Introduction to Check Valves

Check valves are essential industrial components designed to allow fluid flow in only one direction, preventing reverse flow. These valves are crucial in piping systems to protect equipment and maintain stable operation. This article provides a comprehensive analysis of various types of check valves and their applications.

Types of Check Valves

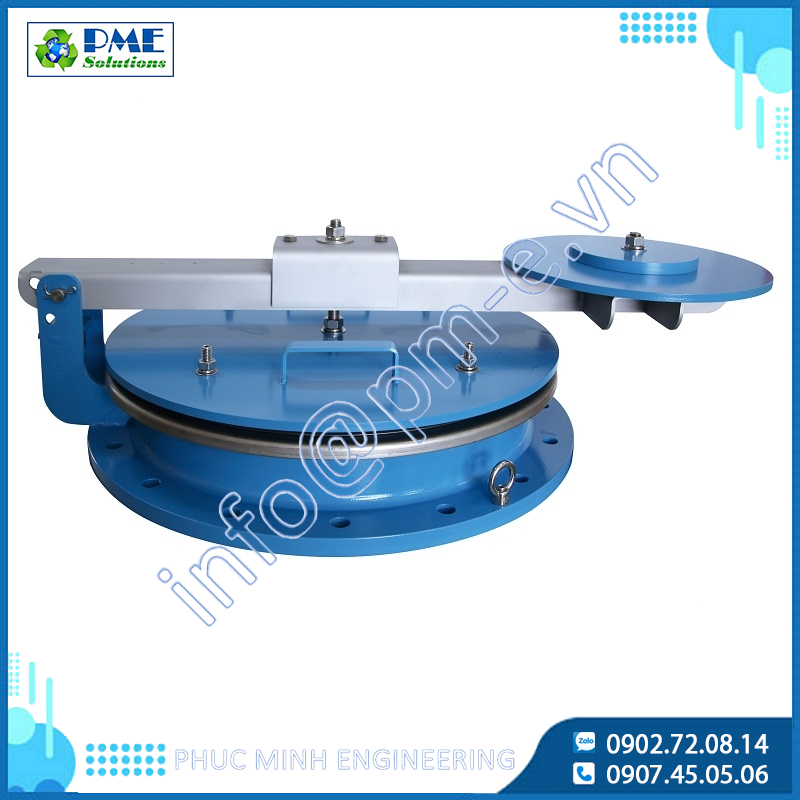

1. Swing Check Valve

Structure: Swing check valves have a hinged disc that allows flow when open and prevents reverse flow when closed.

Advantages:

- Simple design, easy to install and maintain.

- Suitable for low-velocity and low-pressure flow.

Applications:

- Water supply and drainage systems.

- Pump and wastewater treatment systems.

2. Lift Check Valve

Structure: Lift check valves have a disc that moves vertically within a guide. The disc lifts to allow flow and drops to block reverse flow.

Advantages:

- Better high-pressure resistance compared to swing check valves.

- Quick and effective opening and closing.

Applications:

- Oil and gas systems.

- Systems requiring high-pressure resistance.

3. Disc Check Valve

Structure: Disc check valves use a small disc to control flow. The disc moves up and down or rotates to allow or block flow.

Advantages:

- Compact size, ideal for tight spaces.

- Quick response to flow changes.

Applications:

- HVAC systems.

- Small industrial applications and water supply systems.

4. Ball Check Valve

Structure: Ball check valves use a ball to control flow. The ball moves within a chamber to allow flow and seals against a seat to prevent reverse flow.

Advantages:

- Simple, durable design.

- Suitable for flows containing particles or sludge.

Applications:

- Wastewater treatment systems.

- Food and pharmaceutical industries.

5. Diaphragm Check Valve

Structure: Diaphragm check valves use a flexible diaphragm to control flow. The diaphragm moves to allow flow and returns to its position to block reverse flow.

Advantages:

- Excellent reverse flow prevention.

- Suitable for viscous fluids or fluids containing particles.

Applications:

- Chemical and pharmaceutical industries.

- Corrosive fluid and slurry handling systems.

Conclusion

Check valves are effective solutions for controlling flow in piping systems, preventing reverse flow, and protecting equipment. Each type of check valve has its unique structure and advantages, making them suitable for specific applications. Understanding the different types of check valves and their applications will help you select the right product for your system, ensuring efficient and safe operation.

If you are looking for a high quality check valve solution, contact Phuc Minh Engineering to advise and choose the right product for your specific needs, ensuring optimal performance and safety in your operations. your industry.

>>>>See more: Overview of gate valves: Instructions for use and applications

PHUC MINH ENGINEERING COMPANY LIMITED

Address: 92/38 Street 12, Quarter 18, Binh Hung Hoa Ward, Binh Tan District, Ho Chi Minh City

Hotline: +842835352125

Email: info@pm-e.vn

Website: www.pm-e.vn

.png)