Technical Analysis of Various Types of Strainers

Industrial valves are a vital component in modern manufacturing processes and industrial systems. This article will provide an overview of the uses and benefits of industrial valves in various industries.

Introduction to Strainers

Strainers are critical components in fluid systems, designed to remove unwanted particles from liquids and gases, protecting equipment and ensuring smooth operation. This article will analyze different types of strainers, including Y-strainers, T-strainers, basket strainers, and debris strainers, their structures, advantages, and applications.

Types of Strainers

1. Y-Strainer

Structure: The Y-strainer has a compact, Y-shaped design, allowing fluid to flow through a mesh filter that traps particles.

Advantages:

- Compact and space-saving design.

- Suitable for high-pressure systems.

- Easy to install and maintain.

Applications:

- Steam and gas pipelines.

- Chemical processing and petrochemical industries.

- HVAC systems.

2. T-Strainer

Structure: The T-strainer features a T-shaped design, where the fluid flows through a perforated screen or mesh, trapping debris.

Advantages:

- High capacity for dirt and debris retention.

- Easy access for cleaning and maintenance.

- Suitable for large-diameter pipelines.

Applications:

- Water treatment plants.

- Industrial cooling systems.

- Power generation plants.

3. Basket Strainer

Structure: Basket strainers use a cylindrical or basket-shaped mesh that allows fluid to flow while capturing larger debris.

Advantages:

- High debris-holding capacity.

- Easy removal and cleaning of the basket.

- Suitable for large volumes of fluid.

Applications:

- Pump protection systems.

- Industrial water and wastewater treatment.

- Oil and gas processing.

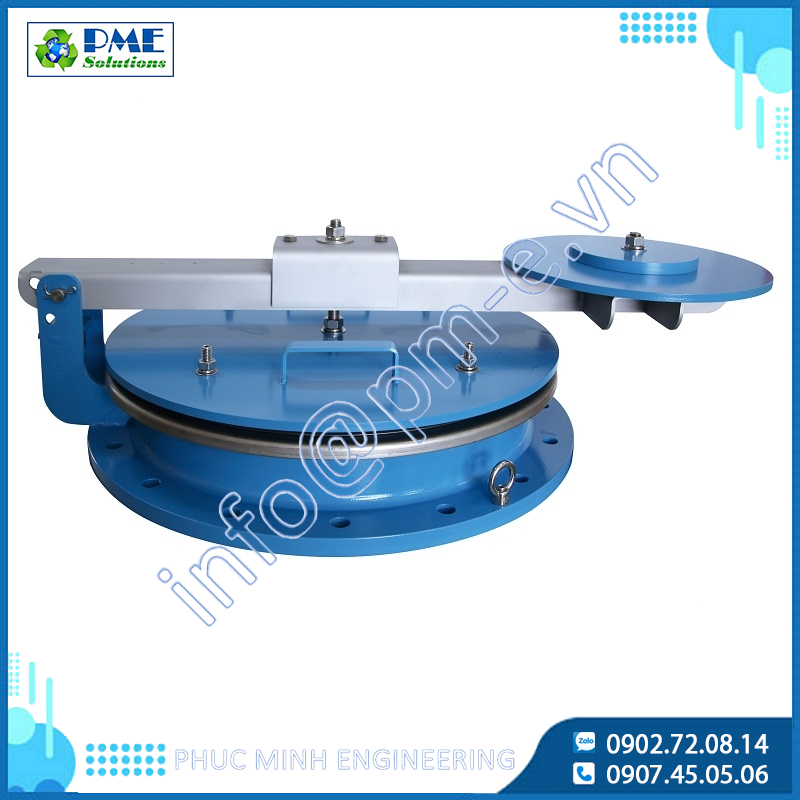

4. Duplex Strainer

Structure: Duplex strainers consist of two basket strainers within a single housing, allowing one basket to be cleaned while the other continues to operate.

Advantages:

- Continuous operation without shutdown.

- High flow capacity and efficiency.

- Easy switching between baskets for cleaning.

Applications:

- Marine and shipbuilding industries.

- Chemical and petrochemical processing.

- Cooling water systems.

5. Debris Strainer

Structure: Debris strainers are designed to capture larger debris and particles from fluid systems, usually featuring a coarse mesh or perforated screen.

Advantages:

- Effective in removing large particles.

- Protects downstream equipment from damage.

- Simple design and easy to maintain.

Applications:

- Municipal water supply systems.

- Irrigation and agricultural applications.

- Raw water intakes.

Conclusion

Strainers are essential for maintaining the integrity and efficiency of fluid systems by removing unwanted particles and debris. Each type of strainer—Y-strainer, T-strainer, basket strainer, duplex strainer, and debris strainer—has specific advantages and applications. Understanding the differences between these strainers will help you choose the right one for your system, ensuring optimal performance and longevity of your equipment.

If you are looking for a high quality strainer /filters solution, contact Phuc Minh Engineering to advise and choose the right product for your specific needs, ensuring optimal performance and safety in your operations. your industry.

>>>>See more: Overview of gate valves: Instructions for use and applications

PHUC MINH ENGINEERING COMPANY LIMITED

Address: 92/38 Street 12, Quarter 18, Binh Hung Hoa Ward, Binh Tan District, Ho Chi Minh City

Hotline: +842835352125

Email: info@pm-e.vn

Website: www.pm-e.vn

.png)