Analysis of check valves.

What is a check valve?

What is a check valve? Why use this valve? When to use? Let's learn about the types, structures, operating principles and practical applications of 1-way valves with Phuc Minh..

What is a check valve? What is check valve?

The English name of the one-way valve is “ Check Valve “. The name tells the definition of this type of valve, that is, a valve that only allows fluid to flow in one direction only, not in the opposite direction, or automatically stops flow when there is reverse flow.

Why control in only one direction?

Let's try to imagine, when the pump fails to work, water from the pipe flows back to the pump. When the fan blows the exhaust air from the plant or machine, it blows to the outside, but due to a malfunction the air blows back. When the wastewater is dirty, the exhaust gas has toxins, the mixed chemical flow flows in the opposite direction… Obviously, it is very bad for the working environment, can cause damage to machinery and equipment, and can even be dangerous. dangerous to humans… We need to control the flow of that liquid or gas.

Then the check valve is used as a safety device, to protect the pipeline system, machinery, further to protect property, environment and people.

What is the structure, operating principle and application of a check valve?

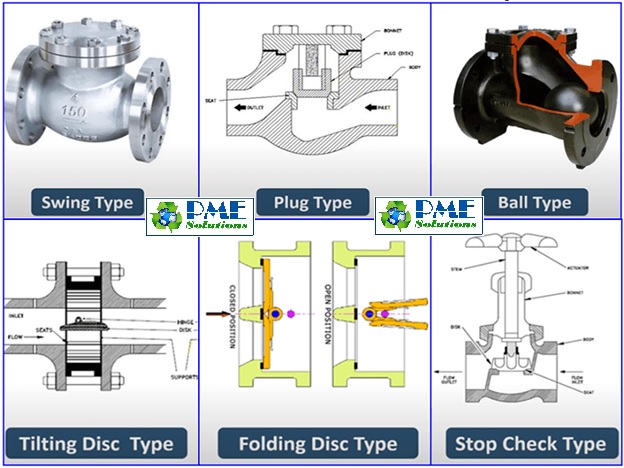

Unlike the 2-way flow valves that we have learned “what is a ball valve, or what is a butterfly valve, what is a gate valve or a globe valve… These valves often have the same structure, only different. about materials, connection types, operating methods. However, with one-way valves, depending on the type, they have different structures, operating principles and applications.

Symbol (check valve Icon) and note for installation with 1-way valve

Learn about " Symbols of valves " we already know how the one-way valve has the symbol. However, depending on the design, in each factory, each project or each different standard, one-way valves have different symbols. Check valves usually use the following symbols.

.jpg)

General note when installing one-way valve

With the common feature of a one-way valve, which only allows fluid to flow in one direction, during installation, it is imperative not to install it in the wrong direction of flow. The direction of flow is specified on the drawing, by arrows, or by the symbol of a one-way valve, to know the direction of flow. When we know the flow direction on the system, we rely on the flow direction on the valve to install it in the same direction. Incorrect installation may damage the system. Or at least the valve does not perform its function.

Leaf check valve

First, let's learn about this most common type of check valve. Because of the simplicity and convenience of the one-way valve with flip-flops

Swing check valve – Swing check valve

1.1 What is a flap check valve?

The flap check valve is a valve, the valve disc is fixed on a hinge that rotates around its pin. At first glance, when the valve works, it will look like a leaf flipping over and over and the flow is one-way, so it is called a one-way valve.

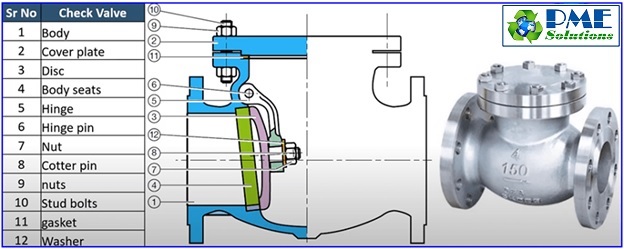

1.2 Flange flap check valve structure

The valve has a basic structure consisting of 12 parts as shown below. In particular, the material of the valve body plays a decisive role in the cost of the product, in addition, the valve disc, valve seat and valve pin are also very important parts that play a role in determining the quality of the valve.

Detail each department and explain in detail the functions and duties of each department

|

No |

Part Name |

Department name – Explanation |

|

① |

Body |

Valve body – Main pressure part, flange mounted on both sides |

|

② |

Cover plate |

Cover plate – Together with the valve body, it forms a unified, fluid-tight block |

|

③ |

Disc |

Valve disc – Hinged, with backflow prevention valve seat |

|

④ |

Body seats |

Valve seat – Creates a seal with the valve disc, preventing flow |

|

⑤ |

Hinge |

Hinge – Together with the hinge pin, rotates the disc face |

|

⑥ |

Hinge pin |

Hinge pin – Creates rotation of the hinge with the disc mounted on it |

|

⑦ |

Nut |

Nut – Used to fix the hinge to the valve disc |

|

⑧ |

Cotter pin |

Disc latch – Fixing valve disc with hinge |

|

⑨ |

Nuts |

Valve cover nuts – Fix the valve cover to the valve body |

|

⑩ |

Stud bolts |

Valve cap bolts – Together with the nut that secures the valve cover to the valve body |

|

⑪ |

Gasket |

Sealing Gaskets – Ensure fluid does not leak from body and lid joints |

|

⑫ |

Washer |

Gasket – Prevents fluid from leaking through the valve disc when in the closed state |

The valve seat and disc are designed in different styles, to meet different requirements, the opening angle of the valve disc is generally from 0° to 45°, and the valve seat is generally designed around 5° to 7°, the design This will minimize the possibility of water hammer. The valve seat is usually a metal ring, with an elastic material attached with a leak-proof feature.

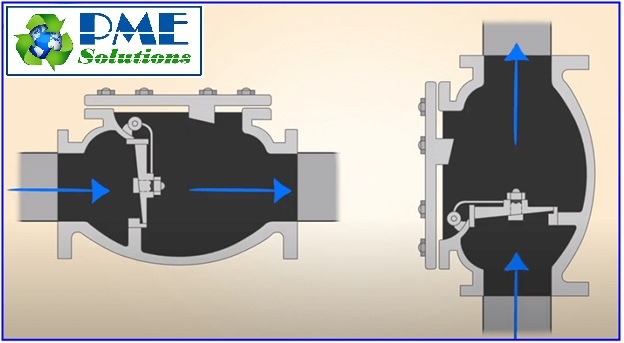

1.3 The principle of operation of one-way leaf flipping

When there is flow, the pressure of the flow pushes the valve disc up and allows the flow to pass through the valve, under the pressure of the flow, the valve is continuously opened to let the liquid flow through. When the flow stops, or when it reverses, by its own gravity, the flap will automatically close to prevent the fluid from flowing in the opposite direction.

.jpg)

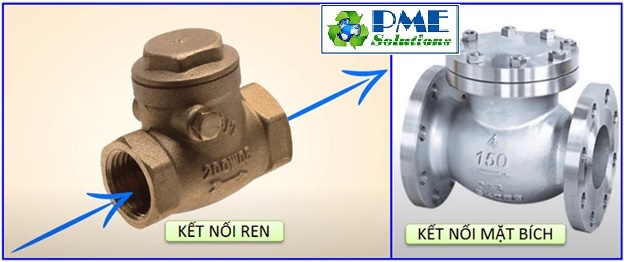

1.4 Flip check valve connection type

According to the connection method, we have flange one-way valve and flange one-way valve with threaded connection. Normally, flap valve usually connects flanges used with pipes from DN50, with valves smaller than DN40 usually connected by thread, because this connection is suitable and flexible in construction and installation. small size pipes

1.5 Materials for the manufacture of check valves

Valves are made of many different materials such as plastic, stainless steel, copper and cast iron. Suitable for many different fluid environments such as clean water - wastewater - water with chemicals... Rich options for users.

In fact, PHUC MINH can provide customers with check valves according to the following table materials

|

Stainless steel swing check valve |

Cast Iron swing check valve |

PVC swing check valve |

|

PP swing check valve |

Bronze swing check valve |

PVDF swing check valve |

1.6 Swing check valve brand

In Vietnam, most of the check valve brands in use are imported from countries with developed industries, because their production technology creates quality products at competitive prices.

|

Tozen swing check valve

|

YDF swing check valve |

Asahi swing check valve |

|

DK swing check valve |

Didtek swing check valve |

Sekisui swing check valve |

|

Tecofi swing check valve |

RITAG check valve |

Hershey swing check valve |

1.7 Origin of swing check valve

Among industrial valve exporters, valves from Japan are rated as the best quality, but the price is relatively high. The valve line from Korea is considered to be very suitable for new industrial park construction projects in Vietnam, because of its good price and quality.

|

Japan swing check valve |

Taiwan swing check valve |

|

Korea swing check valve |

Vietnam swing check valve |

|

US swing check valve |

China swing check valve |

|

France swing check valve |

Germany swing check valve |

1.8 Installation of flap check valve

With the structural characteristics and operating principle of the valve, we see that placing the valve in the right flow direction and valve position is impossible to be wrong. Because if placed in the wrong position, or in the opposite direction of flow, not only the valve has no function, but also prevents the flow. In the case of a pre-installed piping system, attention should be paid to the distance between the two flanges of the valve.

1.9 Application of swing check valve

The swing (flap) check valve is mainly used to protect pipelines, pumping equipment, reservoirs, etc. Used in many different systems, from domestic water, wastewater, to chemical systems. .

1.10 Advantages and disadvantages of flap check valve

Advantages of flap check valve

♠ Compact design, when installed in the system does not occupy space

♠ Automatically open and close, no need to worry about operating space, just maintenance space

♠ Valves with threaded and flanged connections, rich choices for customers

♠ Wide size range, suitable for many pipe sizes

♠ Valves are made from many different materials, very convenient to use for many types of fluids

Disadvantages of flap check valve

∇ The valve has no shaft so it is difficult to know the opening position of the valve disc

∇ In case of liquid with garbage, or hinge latch failure, the valve will stay open continuously despite the reverse flow.

❷ Butterfly check valve – Wafer dual plate check valve ( Folding disc type check valve )

What is a butterfly check valve?

2.1 What is a butterfly check valve?

Butterfly check valve, also known as folding check valve. English also has many different names such as: Folding disc type check valve (Translation: Folding disc check valve) or Wafer check valve (Translation: Plate check valve).

2.2 Construction of one-way butterfly valve

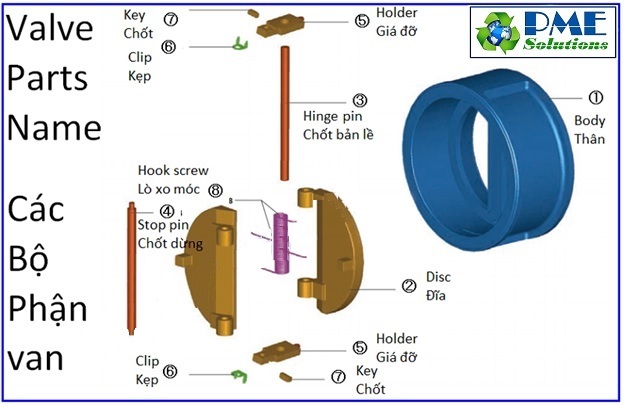

The valve is composed of 7 basic parts, including:

① Valve body – Usually made of cast iron or stainless steel

② Valve disc – Also known as vane is attached to the hinge pin with the hook spring

③ Hinge pin – Is a fixed pin, so that the valve disc rotates

④ The stop pin has the function to prevent the 2 vanes from colliding with each other when fully open

⑤ Bracket – Where to connect and fix the hinge pin to the valve body

Fasteners and Clamps

⑧ Hook spring – The part that creates pressure for the vane is always closed when there is no pressure from the flow in the correct direction

2.3 Operation principle one-way butterfly valve

The valve is in the normally closed state, because the discs are kept closed by the torsion spring. When there is fluid flowing in the forward direction, the pressure of the fluid causes the two discs to open hinges, allowing the fluid to flow through the valve. When the fluid stops flowing, or the flow reverses, the valve disc immediately closes with the force of the spring.

2.4 One-way butterfly valve connection type

The valve has 3 main connection types: Wafer - Clamp connection type, Lug - Flange connection type and Semi Lug - shortened flange connection type. So compared with butterfly valve, this type of valve has no flange connection type

.jpg)

2.5 Vật liệu chế tạo van bướm 1 chiều

Với những loại van này các nhà sản xuất thường đưa ra nhiều chủng loại vật liệu để khách hàng lựa chọn. Thông thường vẫn là các vật liệu chủ yếu như gang, thép đúc, inox.

2.6 Origin – One-way butterfly valve brand

This type of valve in Vietnam market emerged with many brands from Korea, Taiwan, Malaysia and especially China.

|

Germany RITAG dual plate check valve |

DIDTEK dual plate check valve |

|

Wonil dual plate check valve |

Korea dual plate check valve |

|

AUT dual plate check valve |

Malaysia dual plate check valve |

|

Emico dual plate check valve |

China dual plate check valve |

|

DongJin dual plate check valve |

Taiwan dual plate check valve |

|

YDF dual plate check valve |

NEWAY dual plate check valve |

|

KVC dual plate check valve |

US dual plate check valve |

2.7 Installation of 1-way butterfly valve

Bearing common characteristics of one-way valves, structural characteristics and general operating principles. Valves must be installed in the correct flow direction, which is an important requirement. Especially when the flow is vertical, the weight of the fluid must be taken into account.

2.8 Application of one-way butterfly valve

Suitable for applications in a variety of liquid and vapor systems such as water supply and drainage systems, ventilation systems, fire protection systems, thermal engineering systems, air conditioning systems.

2.9 Advantages and disadvantages of butterfly1 way valve

Advantages of valve 1 way butterfly cánh

♠ Compact design, when installed in the system does not occupy space

♠ Automatically open and close, no need to worry about operating space, just maintenance space

Valves are made from many different materials, very convenient to use for many types of fluids.

Disadvantages of butterfly one-way valve

∇ The valve does not have a shaft, so it is difficult to know the opening position of the valve disc.

∇ In case of liquid with garbage, or hinge latch failure, the valve will stay open continuously despite the reverse flow.

∇ The valve is flanged only. With different flange types.

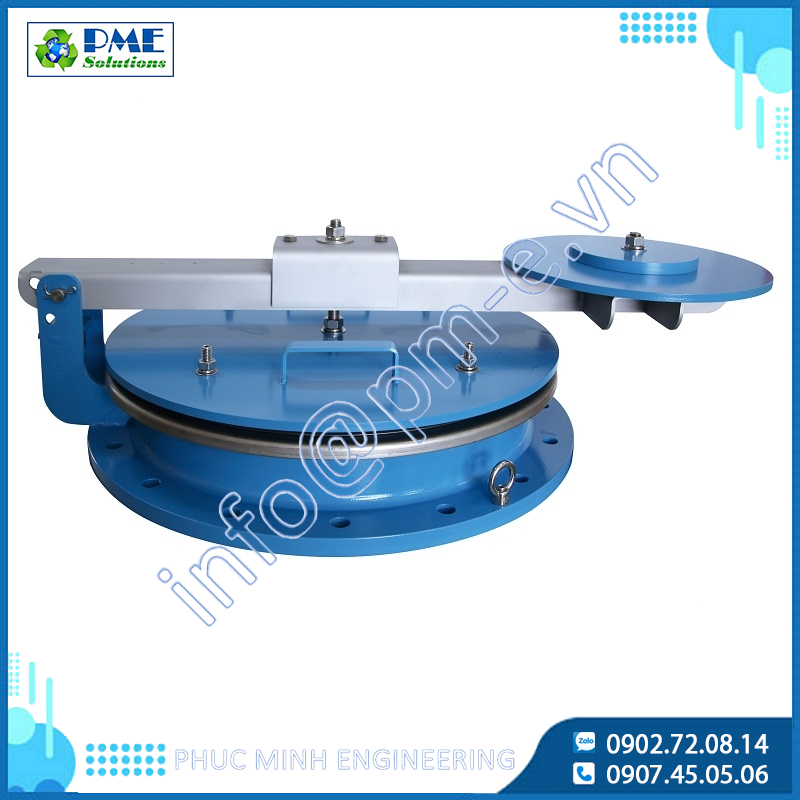

❸ Single disc check valve – Single disc check valve

Similar to the double-blade one-way valve, this single-blade valve works on the principle that, based on the self-weight of the butterfly, to open and close the flow. The valve works on the principle that, thanks to the effect of water flow pressure, pushes the valve disc up and allows the fluid to flow through the valve. When the fluid flow stops flowing, or flows in the opposite direction, by gravity the valve disc itself (in some cases with additional springs), will automatically close the valve.

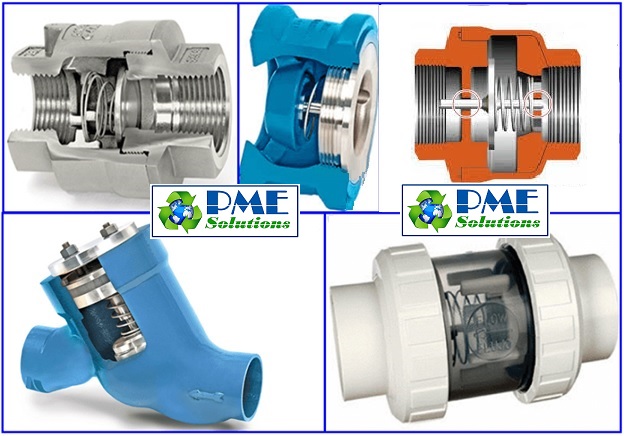

3 Van một chiều kiểu lọ xo là gì? Spring check valve

Van 1 chiều lò xo, còn có tên gọi tiếng anh là Spring Check Valve, là loại van dùng tác dụng của lò xo, đẩy đĩa van về trạng thái đóng. Ứng với loại van này có nhiều kiểu dạng và cách thức hoạt động có phần khác nhau, tuy nhiên đều dựa vào nguyên lý lực tác dụng của lò xo.

General advantages of spring check valve

♠ Valve has a compact design, does not take up installation space

♠ The valve operates fully automatically, thanks to the pressure of the line, no working space is required

♠ The valve body is made from many different materials, has many connections (mainly flange and thread), rich choices for customers.

♠ Simple to disassemble, maintain or replace

♠ With the valve body made from clear plastic, you can observe the opening and closing of the valve

General disadvantages of spring check valves

∇ Operated by the flow pressure and the thrust of the spring, so it is necessary to choose the spring with the appropriate thrust

∇ Spring works in a fluid environment, it is necessary to choose a material suitable for the fluid, to avoid corrosion and rust.

∇ The fluid must be absolutely free of sediment, garbage or solid sludge. Because of the effect on the spring function

∇ Do not control, or check the opening and closing, as well as check the leakage of fluid flowing through the valve in the closed state

❶ Axial check valve – Axial check valve

What is the axial spring of a check valve? It is a spring that is compressed and stretched along a fixed axis, or has a fixed axis to direct the movement of the spring, control and ensure that the spring is not deflected.

What is a axial spring check valve?

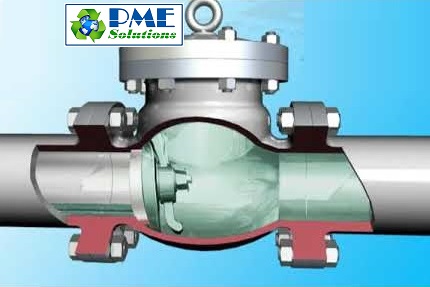

1.1 What is a axial spring check valve?

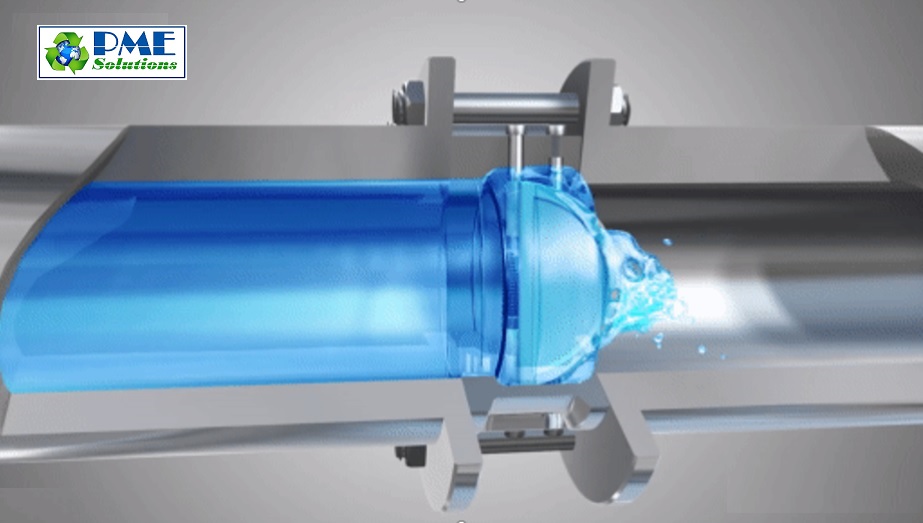

This is a spring-loaded check valve, where the spring is attached to the axis of the valve. The valve disc can be fixed to the shaft, to direct the movement of the disc, or just spring mounted and open and close directly with the movement of the spring.

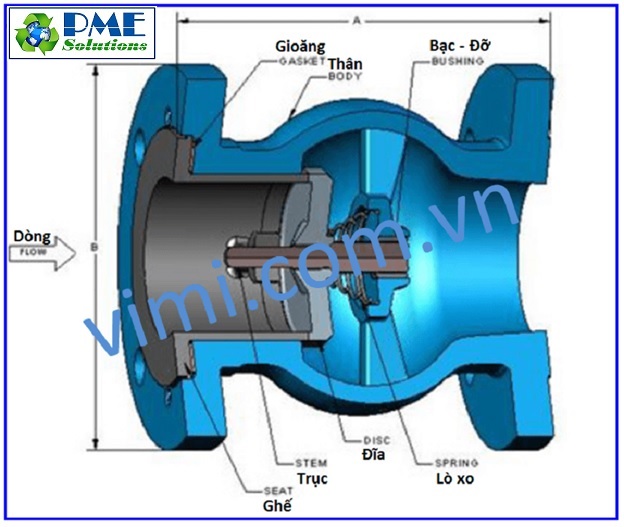

1.2 Construction of axial spring check valve

The structure of this type of spring is simple but ensures good fluid tightness

The body is divided into 2 parts: Made from cast iron or stainless steel, usually the correct body form with 2 flanged connections.

Gasket: Solid, ensuring fluid tightness with EPDM materials or different types of neoprene

1.3 Operating principle of axial spring check valve

We can easily imagine the operating principle of this valve that: When there is fluid, by the pressure of the fluid flow acting on the valve disc, until this pressure overcomes the pressure of the spring, the valve disc. opens and fluid flows through the valve. On the contrary, when there is no this pressure or the flow is reverse, under the action of spring force, keep the valve always in the closed state.

1.4 Shaft spring check valve connection type

Valves are mainly connected by flanges. However, at the request of the customer, some manufacturers can also provide other types of connections, like the connection of a butterfly valve.

1.5 Manufacturing material Shaft spring check valve

Valves are mainly made from cast iron, cast steel and stainless steel.

|

Shaft spring type one-way stainless steel valve |

Shaft spring cast steel one-way valve |

|

Shaft spring cast iron check valve |

Shaft spring plastic one-way valve |

1.6 Brand and origin of axial spring check valve

|

Trademark |

Origin |

|

Wonil axial spring check valve |

Korea Axial spring check valve |

|

Emico shaft spring check valve |

China Spring type check valve |

|

ARV shaft spring check valve |

Taiwan Axial spring check valve |

|

AUT . shaft spring check valve |

Axial spring check valve made in Malaysia |

❷ Y-spring check valve – Y Spring check valve

The same one-way valve line works based on the principle of the force of the spring, but the Y-shaped valve line creates a different flow through the valve than the valve analyzed above, and at the same time better calculates the flow, along with the accuracy of the valve. Better valve durability due to the way the valve is less subject to impact

What is a Y-spring check valve?

2.1 What is a Y-spring check valve?

The name of the valve also helps us to imagine that it is a spring-loaded one-way valve, shaped like a Y shape. The valve automatically opens and closes, based on the pressure of the fluid flow.

2.2 Structure of Y-shaped spring check valve

Valves are usually cast in one block, the protective cover is connected to the body by a system of bolts and nuts. Valve body is made of many materials such as cast iron, copper and stainless steel. Valve discs with springs are usually installed at an angle of 45o to the flow direction

2.3 Operating principle of Y-spring check valve

Valves operate on the principle of automatic opening and closing, by the interaction between fluid pressure and spring thrust. When the pressure of the forward flow overcomes the thrust of the spring, the valve disc will be pushed up and the valve is opened, when the forward flow stops, or the backflow fluid, by its own gravity and the spring's thrust, will push the valve disc to the closed position.

2.4 Material for making Y-shaped spring check valve

Materials for manufacturing a Y-shaped 1-way spring valve. Valves are mainly made of materials such as: stainless steel, cast iron, or copper. Valves are often used with small sizes, connection types are mainly threaded, or welded

2.5 Brand and origin of Y-spring check valve

|

Brand name |

Origin |

|

Taiwan Y-shaped spring check valve |

Korea spring check valve |

|

NVS Y-type spring check valve |

China type spring check valve |

4. What is a gravity check valve? Gravitation check valve

In the types of 1-way valves, gravity-type check valves such as ball valves or 1-way globe valves are used relatively safely because the operating mechanism is less likely to be trapped by garbage or impurities mixed in the fluid.

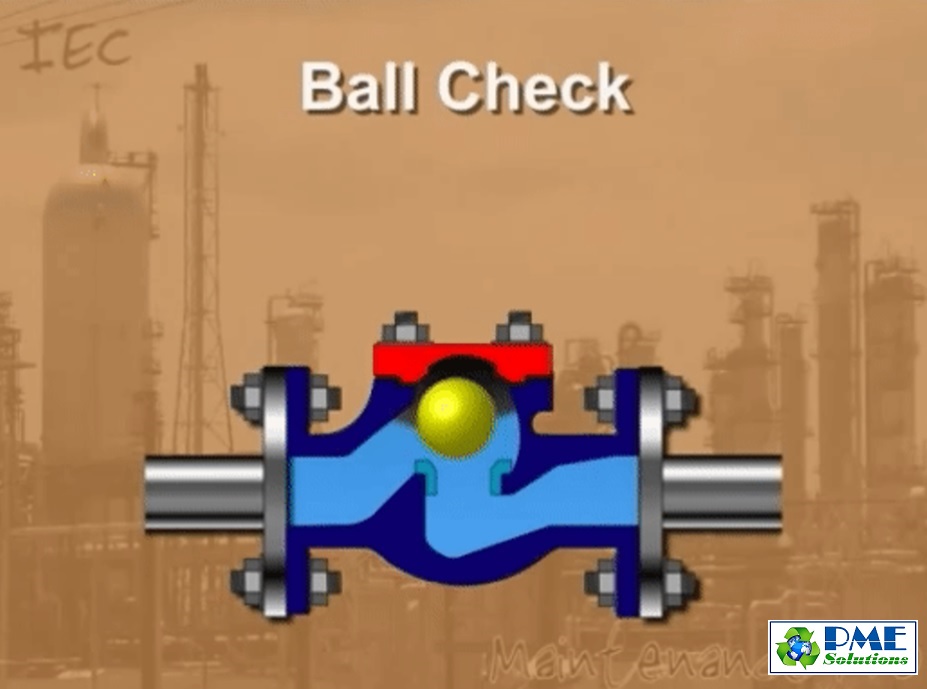

❶ Ball check valve

Valve type works based on the mechanism of self-floating ball when there is fluid or is pushed up by the pressure of the flow. When there is no push from the fluid, the ball will fall down on its own against gravity and seal the valve seat

1.1 What is a one-way ball valve? Working principle

As a one-way valve, in the valve body there is a ball, this ball is light enough to float on the fluid flow, when there is a forward flow (the flow from the bottom of the ball flows up). Conversely, valve automatically closes when the fluid stops flowing or flows backwards (flow from top to bottom).

Valves usually have a globe valve design, especially the Y-type is commonly used, to orient the ball and benefit more from gravity.

1.2 Material and connection type of one-way ball valve

Valves are made of many different materials: Plastic, Stainless steel, cast iron or cast steel

Plastic material: Commonly used as chemical valves, because of the characteristics of this valve is chemical resistance, but the temperature resistance and impact strength of plastic are relatively poor

Stainless steel material: Overcoming the above disadvantages of plastic materials, stainless steel one-way valve is used in chemical systems and systems that require cleanliness, anti-fouling as well as no rusting of steel

Valves have 2 main connection types: Socket - Plastic material valve, flange with metal valve

1.3 Brand – Origin of one-way ball valve

This valve line currently, only a few brands are present in Vietnam

|

Trademark |

Origin |

|

TIS ball check valve |

Italy ball check valve |

|

AVK ball check valve |

Malaysia ball check valve |

1.4 Advantages and disadvantages of one-way ball valves

Advantages of one-way ball valve

♠ Self-cleaning balls

♠ Balls are available in different materials and weights, suitable for each type of fluid

♠ Special ball made from Polyurethane material, with anti-wear feature

♠ Capable of sealing fluids at low pressure

♠ Wide range of sizes suitable for many types of pipes. Flange connection valves are available in sizes from DN 50 – 600.

Threaded connection valve size DN32 - 40. DN32 - 80 is made of both stainless steel material

Disadvantages of one-way ball valve

∇ Water hammer effect caused by the ball +20%

∇ When flowing fluid causes vibration and noise

∇ The ball can be stuck in the valve seat ( Seat ), for metal core ball

❷ One-way globe valve – Stop check valve

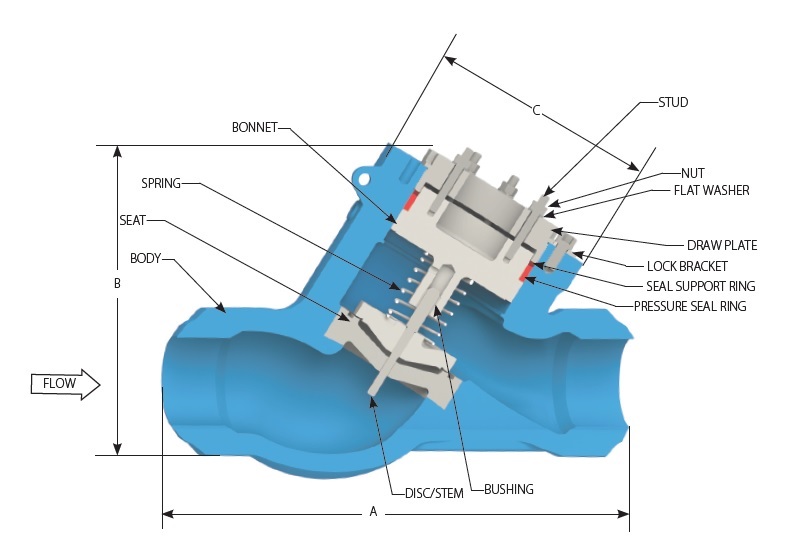

When learning "What is a globe valve", we already know the structure and operating principle of this type of valve. With conventional globe valves, the valve disc is attached to the valve shaft to open and close the valve seat. However, with this valve line, the key difference is that the valve disc and the valve shaft are not fixed, but the valve disc is movable on the valve shaft.

2.1 What is a one-way globe valve?

One-way globe valve, also known as Stop check valve. As a globe valve, with a disc that is not fixed to the valve shaft, the valve disc will automatically close, when there is no flow or reverse flow.

2.2 Construction of one-way globe valve

Similar to the globe valve structure, this type of valve has the following structure: Valve body, cover and bearing, valve disc. The difference between a 1-way globe valve and a normal globe valve is that this type of valve has a disc that is not fixed to the valve shaft. The disc will automatically return to the closed position, when the flow stops or reverses.

2.3 The principle of operation of the one-way globe valve

The one-way globe valve works, based on the self-gravity principle of the valve disc. Normally the valve is in the closed state, due to the gravity of the disc. When the fluid flows in the forward direction, the flow pressure will act on the valve disc, pushing the valve disc up and allowing the flow to flow. When the fluid stops flowing, or reverses, by its own gravity, the valve disc closes automatically.

.jpg)

2.4 One-way globe valve connection type

Globe valves also have a variety of connection types, and the most popular ones are threaded and flanged globe valves. Threaded connection for use with piping systems up to DN40, the pressure limit is not high. Flanged connection type of one-way globe valve, used to assemble on pipes with diameter from DN50 and above.

.jpg)

2.5 Material for making one-way globe valve

The materials for manufacturing one-way globe valves are usually cast iron, steel, stainless steel, etc., which helps buyers choose the right product suitable for the working environment. For environments with chemical components, people use valves with stainless steel materials, with high-pressure fluids using steel valves, used wastewater or normal feed water, cast iron valves are suitable for use. more suitable.

2.6 Origin – One-way globe valve brand

The quality brands that supply globe valves that we may be interested in are those from Japan and Korea such as: tecofi, tozen, wonil, kitz, toyo, etc.

|

Trademark

|

Origin |

|

Tozen globe check valve |

Japan |

|

Tecofi globe check valve |

France |

|

DK Valve globe check valve |

Korea |

|

Conval globe check valve |

USA |

|

Wonil globe check valve |

Korea |

2.7 Guide to install one-way globe valve

With the structure and operating principle of the globe valve, when installing, it is imperative to direct the handwheel upwards, to ensure that the valve disc automatically returns to the closed position of the valve. In case of handwheel, downward or horizontal direction, it means that the valve disc will not automatically return to the closed position. At that time, van hong still functions as its name suggests.

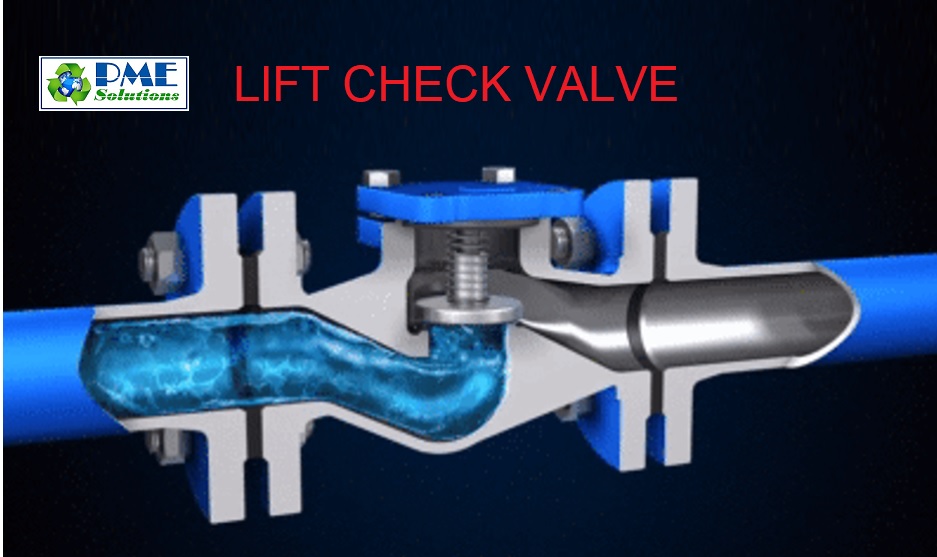

5 What is a lifting type check valve? Lift check valve

Another type of check valve, used mainly in specialized systems - special specialties, in common piping systems have almost no chance of being seen.

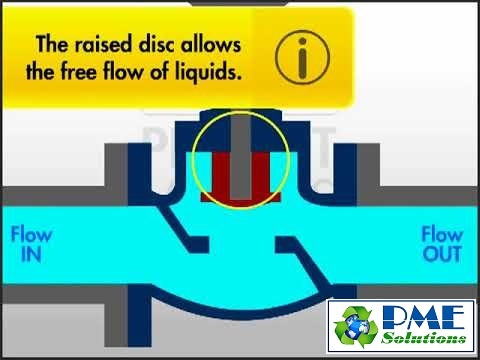

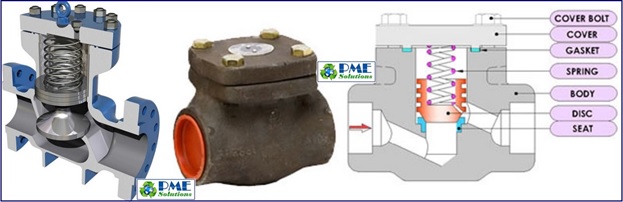

❶ What is Lift check valve? Valve structure

As a one-way valve where the valve disc is usually in the form of a piston or spring, valve has the same shape as a globe valve, but does not use a handwheel. Operates on the principle of self-opening when the forward flow pressure overcomes the force of the spring or piston. Automatically closes when stopping the forward flow, or the reverse flow.

❷ Construction of lift check valve

The valve has the same shape as the globe valve, the key difference is, the globe valve uses the valve shaft attached to the valve disc, and the lift check valve uses a spring attached to the valve disc. For the same reason, this type of valve usually does not use a handwheel.

❸ Operating principle of lift check valve

When the pressure of the fluid flows in the forward direction, overcome the thrust of the spring or piston. The valve disc is raised from the valve seat, when fluid flows through the valve. On the contrary, when the fluid pressure flows forward, the spring thrust cannot be overcome, or when the flow stops, or flows backwards. By the action of the spring, the valve disc is pushed back to the closed position, creating a closed contact surface with the valve seat.

❹ Check lift vale connection type

Most valves are flange-connected, because valves are mainly used in piping systems with relatively high pressures and often contain chemical flows. In addition, flange connection, convenient in adjusting the valve position, as well as during disassembly for maintenance and replacement.

❺ Application of check lift valve

Valves are commonly used for venting, air conditioning, or compressed air systems. Systems where the fluid has a high flow rate and pressure.

.png)